5

Dispose of the packing in an

environmentally friendly manner.

Clean all rust protected surfaces with

a mild solvent.

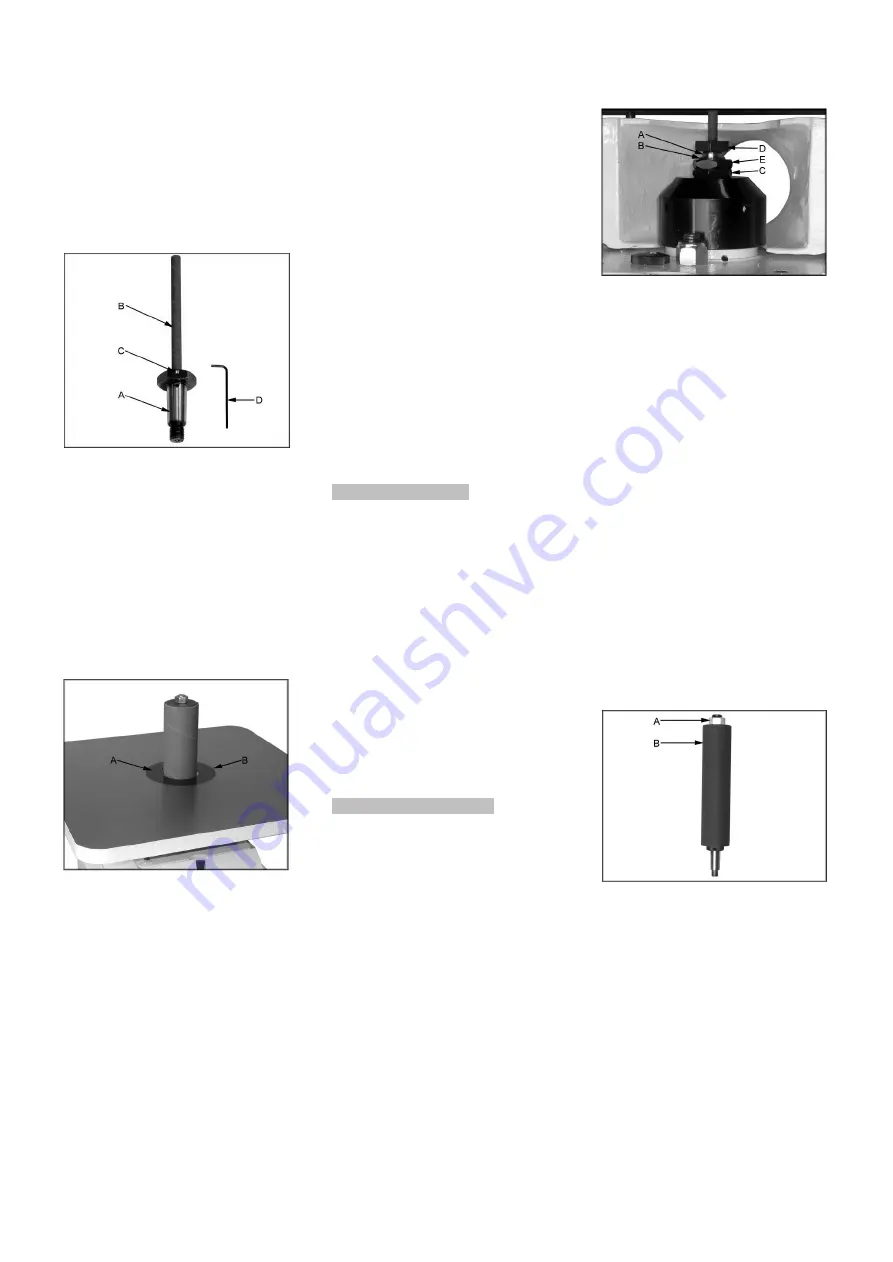

Thoroughly clean the arbors ( A, Fig

1) on all of the spindle assemblies.

Also clean the arbor housing on the

sander.

Fig 1

Slip the sanding sleeves (B) over the

spindle and hold in place by tightening

the screw (C) with the supplied 2mm

hex wrench (D)

Install the sanding spindle to the

sander (see chapter 7.1)

Install the table insert (A, Fig2) which

most closest fits the sanding sleeve.

Line up the notch in the insert with the

pin in the table (B)

Fig 2

5.3 Mains connection

Mains connection and any extension

cords used must comply with

applicable regulations.

The mains voltage must comply with

the information on the machine

licence plate.

The mains connection must have a

10 A surge-proof fuse.

Only use power cords marked

H07RN-F

Connections and repairs to the

electrical equipment may only be

carried out by qualified electricians.

5.4 Dust connection

Before initial operation, the machine

must be connected to a dust collector.

The suction should switch on

automatically when the sander is

switched on.

The flow rate on the 100mm suction

port must be 20m/sec.

Flexible hoses must be of non-

flammable quality, and must be

connected to the dust collector ground

system.

5.5 Starting operation

You can start the machine with the

green on button. The red button on the

main switch stops the machine.

6. Machine operation

Feed the workpiece straight across the

machine table, holding your fingers

close together, guiding the workpiece

with the palm of your hands.

Don’t put your hands under the

machine table.

Always keep your hands well clear of

the rotating sanding drum.

When working complex shapes, make

jigs and guides to guide the workpiece

properly and safely.

Support long workpieces with helping

roller stands.

For bevel sanding the table can be

tilted

7. Setup and adjustments

General note:

Setup and adjustment work may

only be carried out after the

machine is protected against

accidental starting by pulling the

mains plug.

7.1 Installing spindles

Disconnect the machine from the

power source.

Before inserting the threaded spindle

(A, Fig 3) into the spindle holder (B)

make sure the surfaces are clean.

Fig 3

Using the provided wrenches, tighten

the arbor nut (D) colckwise while

holding the lower arbor housing nut

(C) with the other wrench.

Do not over tighten the spindle as it

may be difficult to remove.

Removing Sanding spindles:

Disconnect the machine from the

power source.

Use the provided wrenches to hold the

upper arbor housing nut (E, Fig 3)

while turning the arbor nut (D) counter

clockwise.

7.2 Changing sanding sleeves

Disconnect the machine from the

power source.

On the 6, 9, 12, 16mm spindles

loosen the sleeve clamp screw

(C, Fig 1).

On the 19, 25, 38, 50, 75 and 100mm

spindles loosen the nut (A, Fig 4).

Fig 4

Remove the sanding sleeve from the

spindle shaft or drum.

Reverse these steps to install the new

sanding sleeve.

7.3 Setup for 90°

Disconnect the machine from the

power source.

Use a square (E, Fig 5) on the

sanding drum to exactly align the

table to 90°.