11

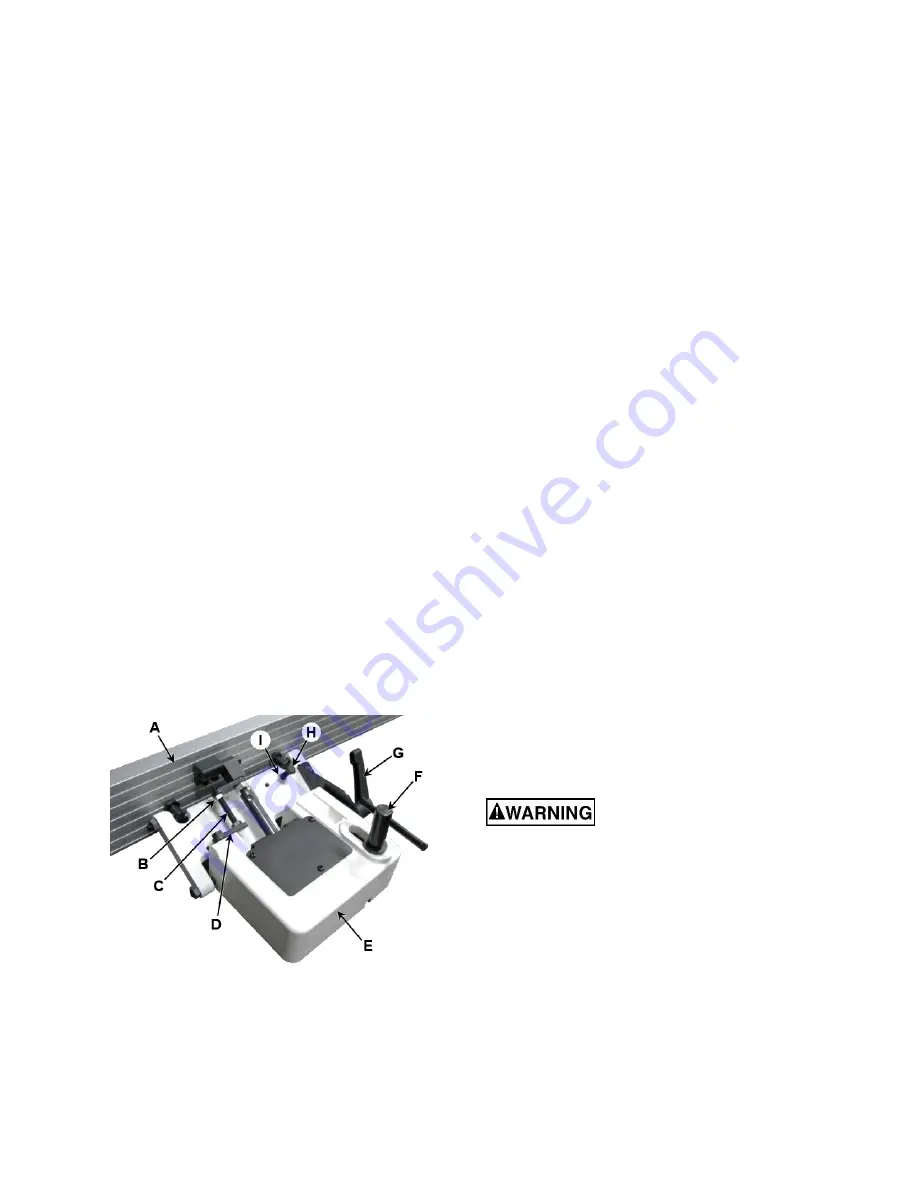

5. If the

fence

(A) is not square to the table,

release the

tilt locking handle

(G), loosen the

lock nut

(B), and turn the

stop bolt

(C) until

the fence is square to the table.

6. Tighten the

lock nut

(B) to retain the setting.

Tighten the

tilt locking handle

(G).

45° Backward Stop Fence Adjustment

The 45º fence backward stop (fence positioned

away from the operator) is controlled by the

backward stop bolt

(H).

1. Set the

infeed table

(F, Fig. 7) to approx-

imately the

same height as the

outfeed table

(A, Fig. 7).

2. Move the

fence

(A) by releasing the

assembly locking handle

(F) and pushing the

fence assembly

(E) until it overlaps the

tables, then tighten the

assembly locking

handle

(F).

3. Adjust the

fence

(A) to a 135° angle by

releasing the

tilt locking handle

(G), moving

the

stop plate

(D) out of the way, and

positioning the fence against the

backward

stop bolt

(H). Tighten the

tilt locking handle

(G).

4. Place an angle measuring device on the table

and against the

fence

(A) to confirm a 135º

setting.

5. To adjust, loosen the

tilt locking handle

(G)

and

lock nut

(I), then turn the

backward stop

bolt

(H) until a 135º angle is obtained.

6. Tighten the

lock nut

(I) to retain the setting.

Tighten the

tilt locking handle

(G).

Figure 9

10.2

Table and Knife Adjustments

For accurate jointing, at least three things must

be true:

1. Infeed and outfeed tables must be coplanar.

2. Knives or knife inserts must be set in the

cutterhead so that the highest point of their

arc is level with the outfeed table.

3. On the standard cutterhead, knives must be

parallel with the outfeed table across the

entire length of the knives.

These alignments are explained below.

10.3

Coplanar Alignment

Definition of Coplanar

When the infeed table is set to the same level as

the outfeed table and all points on the tables lie in

the same plane, thus forming a

“perfect” flat

surface, the tables are said to be coplanar.

For optimum performance of the jointer, the

infeed and outfeed tables must be coplanar. If

they are not, the finished workpiece may have a

slight taper or twist across its jointed width or

length.

Determining If Tables Are Coplanar

Refer to Figures 10 and 11:

The tables have been set coplanar at the factory,

but they should be double-checked by the

operator. Also, as the machine undergoes use,

the tables should be checked occasionally and

adjusted if necessary.

The procedure described below uses a steel

straight edge to set the tables, which should be

accurate enough for most purposes.

Important:

The tables must be locked in position

when performing the following test.

Disconnect machine from

power

source

before

making

any

adjustments. Failure to comply may cause

serious injury.

1. Disconnect machine from power source.

2. Fully swing the

cutterhead guard

(G) away

from the

fence

(B). It is recommended to then

use a

6mm hex wrench

(F) (one is included

with the machine) as a makeshift stop to hold

the guard in place. To do this, insert the

wrench into the front right roller tension

adjustment screw. The cutterhead guard can

then be released and the wrench will prevent

it from swinging back towards the fence.

Summary of Contents for JPJ-12B

Page 28: ...28 15 1 Infeed Table Assembly Exploded View ...

Page 30: ...30 15 3 Outfeed Table Assembly Exploded View ...

Page 32: ...32 15 5 Cutterhead Assembly Exploded View ...

Page 34: ...34 15 7 Planer Table Assembly Exploded View ...

Page 36: ...36 15 9 Blade Guard Assembly Exploded View ...

Page 38: ...38 15 11 Gearbox Assembly Exploded View ...

Page 40: ...40 15 13 Cabinet Assembly Exploded View ...

Page 43: ...43 15 15 Fence Assembly Exploded View ...

Page 45: ...45 16 0 Electrical Connections for JPJ 12B JPJ 12BHH ...

Page 47: ...47 ...

Page 48: ...48 427 New Sanford Road La Vergne Tennessee 37086 Phone 800 274 6848 www jettools com ...