10

Step 8 is optional:

Further secure the dust chute by reinstalling the hex nut

(B1) and flat washer (B2) from underneath the planer infeed

table (F1).

Remove handle (S).

Important:

Dust chute (B) must be properly installed in both jointer-

planer and thicknesser setup.

If improper installation fails to activate a micro-switch, the

machine will not start.

Adjustments:

Loosen the clamping knobs (F) for infeed table adjustment.

Adjust depth of cut with knob (E).

Retighten the clamping knobs.

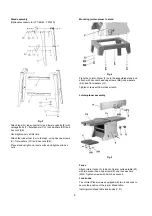

Fig 9

Loosen clamping handle (J) for fence adjustment. Retighten

clamping handle.

Correct operating position:

Position yourselves offset to the infeed table (Fig 10.

Fig 10

Work piece handling:

Feed the work piece straight across the infeed table, holding

your fingers close together, guiding the work piece with the

palm of your hands.

Never put your hands under the cutter block cover.

Always keep your hands well clear of the cutter block

Do not pull the work piece back over the unguarded cutter

block

Always plane the work piece over its entire length.

Support long work pieces (longer than jointer tables) with

helping roller stands or table extensions.

Planing the face of a work piece up to 75mm thick:

Place the work piece against the jointer fence. Adjust the

cutter block guard to the height of the work piece. When

guiding the work piece, the hands slide over the cutter block

guard (Fig 11)

Fig 11

Planing the edge of a work piece (jointing) or planning

work pieces more than 75mm thick:

Place the work piece against the jointer fence.

Adapt the cutter block guard to the width of the work piece

(Fig 12).

Fig 12

Chamfering a work piece:

Place the work piece against the jointer fence.

Adapt the cutter block guard to the width of the work piece

(Fig 13).