14

8. Maintenance and inspection

Make all machine adjustments or maintenance

with the machine unplugged from the power

source.

Clean the machine regularly

Inspect the proper function of the dust extraction daily.

Defective safety devices must be replaced immediately.

Before starting any work, check the mobility of the anti-

kickback fingers (must fall down by their own weight).

Changing of brushes:

Disconnect from power source, unplug!

Inspect the brushes after 50 hours of use.

Fig 24

If the brushes are worn to 3mm replace them.

(Jet Article No: JJP8BT-169…2 pcs needed)

Changing of belts:

Disconnect machine from power source.

Risk of personal injury by cuts from the sharp cutter knives.

Use extreme caution to avoid contact.

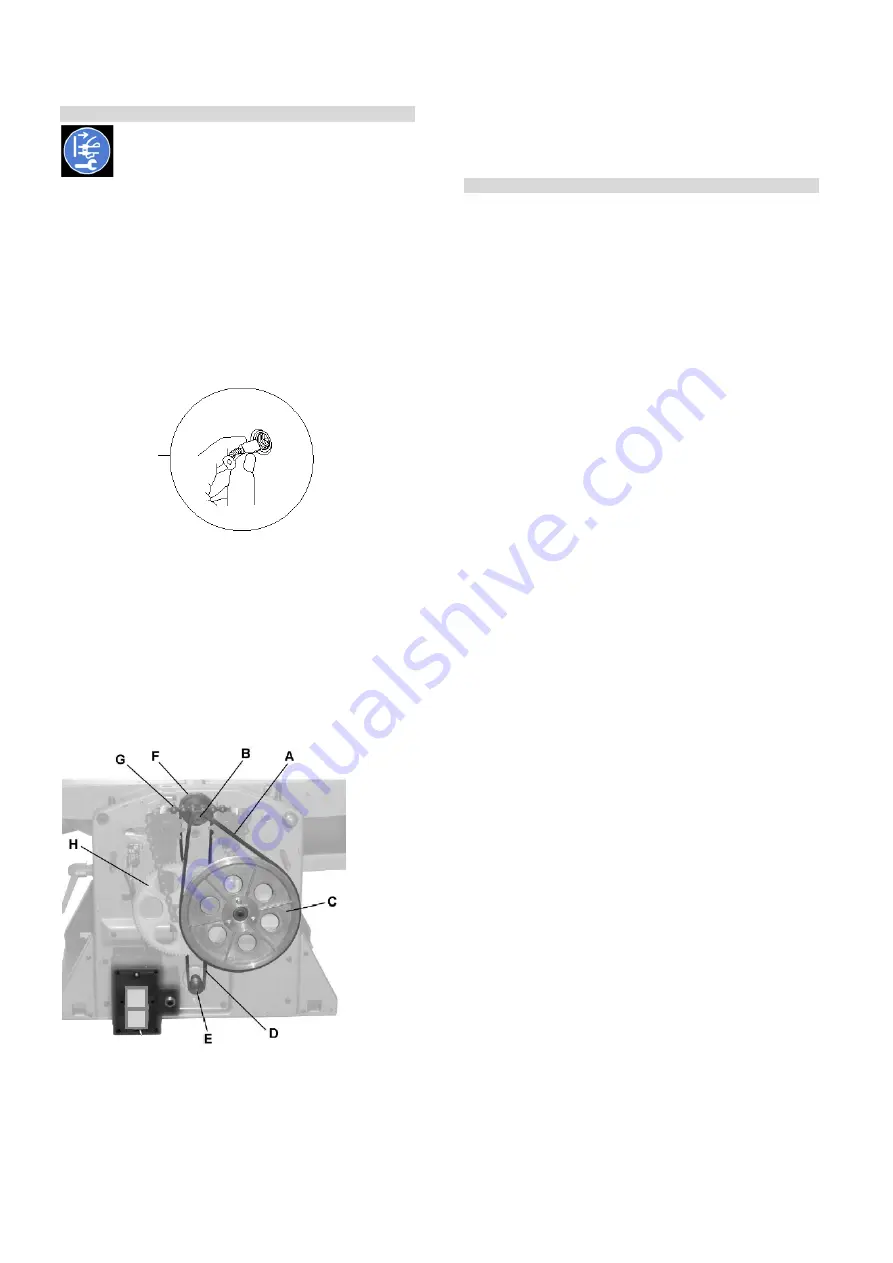

Fig 25

Remove the machine front cover.

Replace feed-roller belt (A), or main drive belt (D).

Reinstall the front cover.

9. Trouble shooting

Carry out maintenance, cleaning and repair work only when

the motor is switched off and machine has come to a full

stop. Pull the mains plug.

All protective and safety devices must be re-attached

immediately after completed cleaning, repair and

maintenance work.

Repair and maintenance work on the electrical system may

only be carried out by a qualified electrician.

Motor doesn’t start

*No electricity-

check mains and fuse.

*Defective switch, motor or cord-

consult an electrician.

*Overload has reacted-

Wait 5 minutes, push overload button and start again.

Machine vibrates excessively

*

Stand on uneven floor-

adjust stand for even support.

*knives of different seize-

all knives must have same width.

*damaged knife-

replace knives set immediately

Cutting surfaces is bad

*dull knives-

sharpen knives

*Cutter knives blocked by chips-

remove chips.

*Too heavy a cut-

make several passes.

*knives cutting against grain-

plane workpiece in opposite direction.

*workpiece inhomogeneous

*Moisture content too high

Snipe

*Inadequate support of long boards-

use extension roller.

*dull knives-

sharpen knives.

*Knives set too high-

adjust the knives

*Work piece twisted-

surface plane work piece before thicknessing.

Non parallel side to side

*

knife projection not uniform-

adjust knives with setting gauge.

Workpiece jams

*

Too much material removed in one pass-

make several passes.