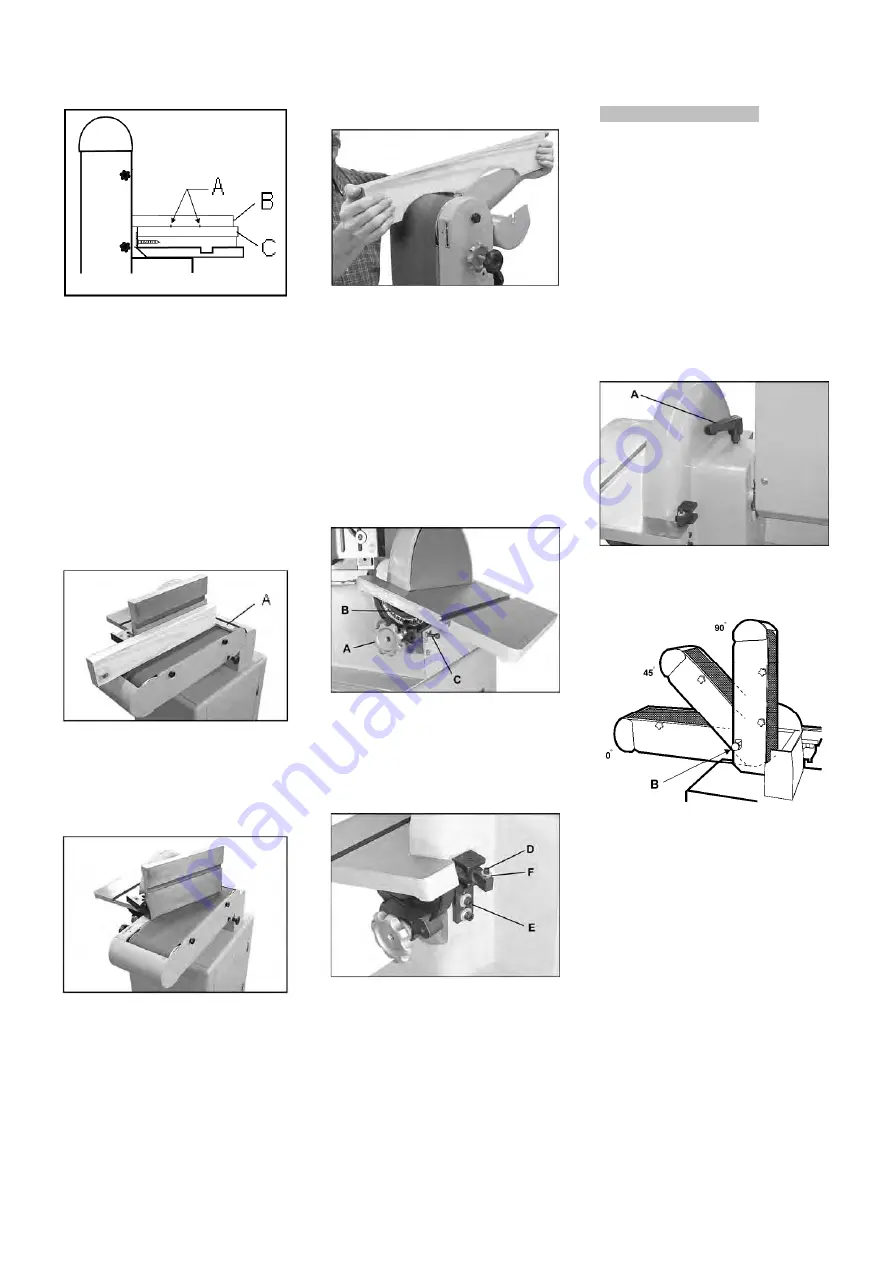

Fig 3

For pattern sanding the workpiece (B,

Fig 3) is mounted to a sanding

template (C) with nails (A).

6.2 Horizontal belt sanding:

When sanding in the horizontal

position, the table attachment may be

positioned as sanding fence (see

chapter 7.2).

The fence can be tilted at any angle

between 90° and 45°.

The work stop (A, Fig 4) must be

installed to stop the workpiece.

Fig 4

The fence can be angled across the

sanding belt for scew sanding (Fig 5).

Fig 5

6.3 Contour belt sanding:

Can be done with the idler pulley end

cover swung open (Fig 6).

Fig 6

Caution:

Bring the end cover back in

protecting position immediately

after contouring operation.

6.4 Disc sanding:

The sanding table may be adjusted at

any angle from 15° up to 45° down.

An adjustable 45° stop (C, Fig 7) is

located under the table.

Fig 7

An adjustable 0° stop (F, Fig 8) is

located on the back of the machine

and must be swung out of position for

the table to be tilted down.

Fig 8

7. Setup and adjustments

General note:

Setup and adjustment work may

only be carried out after the

machine is protected against

accidental starting by pulling the

mains plug.

7.1 Belt arm positioning

Loosen the indexable knob (A, Fig 9)

and pull out the lock pin (B, Fig 10) so

that the sanding belt can be rotated to

the desired working position.

Fig 9

The lock pin can index at 0°, 45° and

90° (Fig 10).

Fig 10

7.2 Belt table/ fence setup

To angle the table across the sanding

belt loosen the two socket head

screws (B, Fig 11).

Rotate the table attachment by sliding

it around the screws using the curved

slot (C).