12

Assembly

Tools required for assembly:

4mm Hex Key

6mm Hex Key (provided)

13mm open-end wrench

(2) 11/16” wrenches or sockets

Machine is heavy! Use

caution when lifting out of the shipping

carton and moving to a final location. Stand

or bench must be stable enough to support

heavy weight.

1. Use a hoist with straps to remove the

Sander from the carton. Prevent straps from

contacting any levers or switches while

lifting.

2. Carefully position the machine on a

workbench or one of the optional JET

stands. (Consult the assembly instructions

that accompanied the stand.)

3. Bolt the unit firmly to secure it in position.

Figure 11 shows it being bolted to the

optional closed stand. Use the four M10x80

hex cap screws, with M10 lock washers, flat

washers and hex nuts. Tighten hex nut

while holding the screw head stationary,

using two 11/16” wrenches. Remove lifting

straps.

4. Exposed metal surfaces have been factory-

coated with a protectant. Remove this using

a soft cloth and a solvent or cleaner/

degreaser. (Note: Keep solvents away from

painted surfaces and plastic parts, and do

not use an abrasive pad, as it may scratch

the polished metal surfaces.)

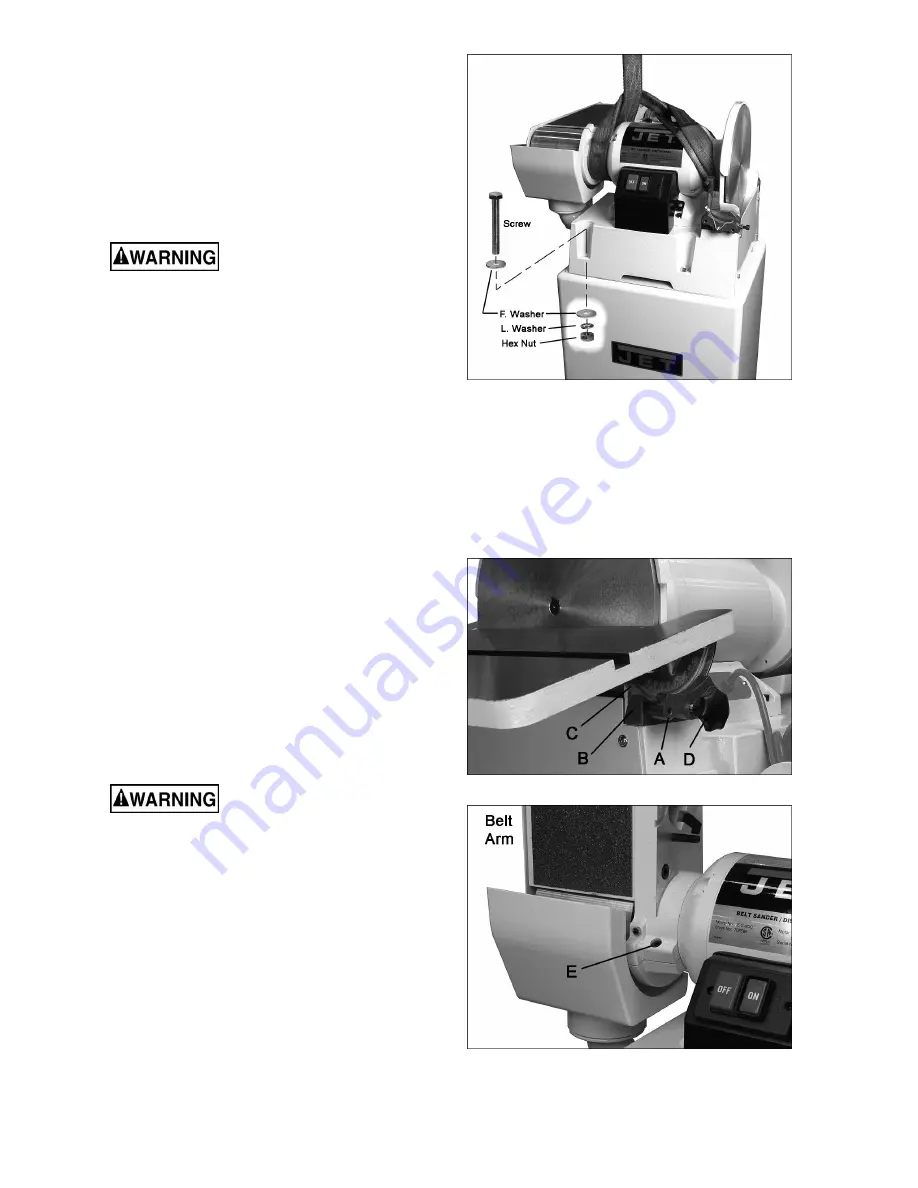

Machine should be dis-

connected from power during all assembly

procedures.

Disc Table

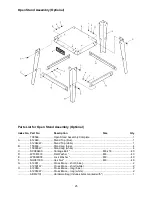

1. Remove the left and right trunnion brackets

(A, Figure12) from the trunnion holder (B).

2. Make sure the stop block (shown in Figure

23) is flipped out of the way.

3. Place the disc table on top of the trunnion

assemblies and position each trunnion

bracket (A) so that it slips onto the threaded

stud and two pins of the trunnion holder (B),

while engaging the lip of the table trunnion

(C).

Figure 11

(closed stand optional)

Figure 12

Figure 13

Summary of Contents for JSG-6DC

Page 20: ...20 JSG 6DC Belt Disc Sander Assembly...

Page 26: ...26 Electrical Connections...

Page 27: ...27...