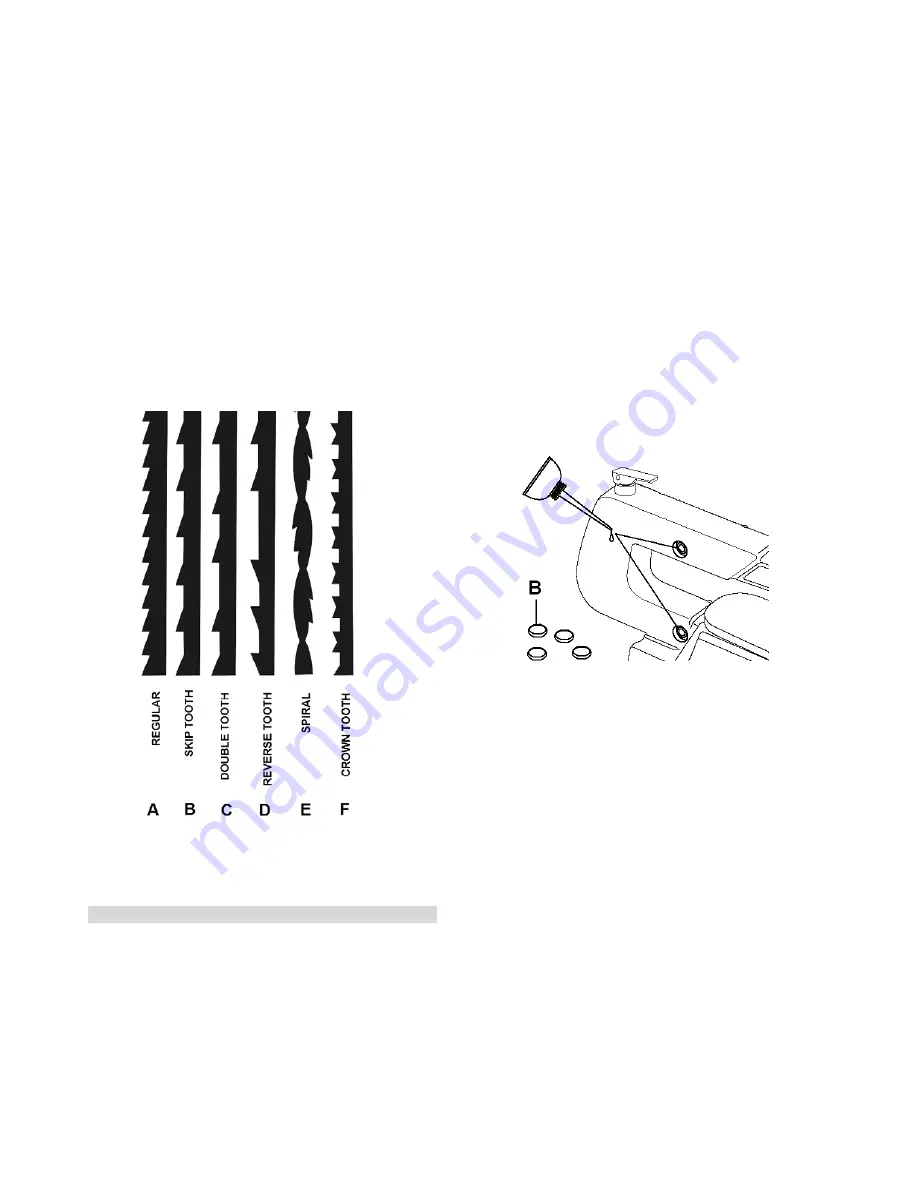

Tooth form :

Tooth form (Fig 30) has an effect on cutting rate.

‐ Regular (A)

Standard blade form with evenly spaced teeth

and zero‐degree rake angle. Offers clean cuts at slower feed

rates.

‐ Skip tooth (B)

More space between teeth, for good chip

removal and fast cuts.

‐ Double tooth (C)

A skip tooth with larger gaps between

tooth sets; good chip removal, fast cutting.

‐ Reverse tooth (D)

Prevents underside tear‐out, leaves clean

edge.

‐ Spiral (E)

Cuts on all sides without turning workpiece; good

for narrow fretwork.

‐ Crown tooth (F)

Cuts on both up and down strokes; good for

clean, splinter‐free edges.

A crown tooth blade may often be turned over for a fresh set

of cutting teeth.

Fig 13

9. Maintenance and inspection

General notes:

Maintenance, cleaning and repair work may only be carried

out after the machine is protected against accidental starting

by pulling the mains plug.

Repair and maintenance work on the electrical system may

only be carried out by a qualified electrician.

Clean the machine regularly.

Inspect the proper function of the dust extraction daily.

All protective and safety devices must be re‐attached

immediately after completed cleaning, repair and maintenance

work.

Defective safety devices must be replaced immediately.

Cleaning:

Regularly clean the machine housing with a soft cloth

preferably after each use.

If the dirt does not come off use a soft cloth moistened with

soapy water.

Never use solvents such as petrol, alcohol, ammoniac water,

etc. These solvents may damage the plastic parts.

Saw blades:

Only use sharp saw blades.

Lubrication:

Lubricate the arm bearings after every 50 hours of use.

Fig 14

Remove the 4 bearing covers (B, Fig 14).

Apply a generous amount of light oil (SAE 20).

Replace the bearing covers.

Motor brushes:

The collector brushes are due to wear and may need

replacement.

‐ Disconnect the machine form the power source, pull mains

plug.

‐remove the brush covers.

‐Replace the collector brushes (Jet Article Number: JSS16A‐079

….2 pieces needed).

‐reattach the brush covers.