9

Set-up and Installation

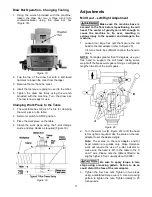

Preparing the Milling Machine for Service

1. Remove any crating which may be covering the

machine on the pallet.

2. Remove accessory items from the pallet or

machine table. Compare these items with the list

on the previous page.

3. Check the tightness of the lifting ring on the ram

to be certain it is tight.

4. Check the tightness of the lock handles on the

ram (see Figure 23) to be certain the ram is

locked tight.

5. Remove the nuts and/or bolts, which secure the

machine to the pallet.

6. Center an overhead crane or other suitable

overhead lifting device and sling arrangement

over the lifting ring.

Note:

This machine weighs over 2400 pounds!

Be certain the lifting arrangement is new or in

excellent condition and has a safety factor that

will account for age, difficulties in lifting, etc.

When lifting using the ring, the machine will tip

forward. If you wish, you can minimize this tipping

by rigging a support sling over the front of the

machine. Be careful when doing this, to prevent

the sling from damaging any components on the

front of the machine. Be sure to steady the mill to

prevent it from spinning.

7. Lift the machine off the pallet no higher than

necessary to clear the hold-down hardware, then

pull the pallet out of the way. Do NOT get hands

or feet underneath the machine when removing

the pallet!

8. Put the machine base over the hold-down system

where the machine will be spotted. Anchor bolts

of sufficient size and length must be fastened to

the floor according to the footprint of the mill. See

diagram on page 10.

Note:

The accompanying diagrams show you the

maximum dimensions of the machines with the

table, ram, etc., fully extended in all possible

directions. When spotting the machine be certain

to leave room not only for the machine itself, but

also for operator clearance and clearance for

workers servicing the machine, and any unusual

sizes of workpieces that might extend off the

machine’s table.

9. When the machine is over its anchors, level the

machine using shims under the corners needing

them. The machinist’s level used for leveling

should be placed on the table. The table is the

reference surface for both side-to-side and fore-

and-aft leveling. Be certain you get it level in

BOTH directions.

Mill must be supported equally

under all four corners. Failure to comply may cause

the column to twist and put a bind in the table ways.

10. When the machine is level, secure the base to

the anchor system.

IMPORTANT:

Before attempting to raise the mill

head, refer to Mill Head – Left/Right Adjustment in

the

Adjustments

section for procedures to safely

raise and set up the mill head.

11. Loosen the four hex head nuts (see A, Figure 22)

about 1/4 turn each (counterclockwise), just

enough to allow rotation of the head.

12. While assisting the worm mechanism by putting

upward pressure on the motor by hand, use the

wrench supplied with the machine to turn the

worm nut and raise the head to upright position.

13. Tighten the headbolts slightly — not torqued —

just snug.

14. Using mineral spirits or other cleaning solvent,

clean all of the rust proofing from where it may

have been applied. This is important; moving the

table or any other components before removing

the rust proofing will only put rust proofing where

you don’t want it.

Some of the following steps may have already

been performed on the machine. If so, ignore the

instructions related to those particular steps.

Otherwise, perform them in the order listed,

referring to Figure 11 for any clarification.

15. Install the table traverse and cross-feed cranks

on their respective shafts using the nuts on the

shafts to secure the cranks.

16. Remove any rust proofing from the drawbar and

its washer, and put the drawbar with washer

installed into the spindle center through the top of

the machine.

17.

Slide the fine feed handwheel over the

handwheel hub and push it back until its rollpin

engages the hole in the hub and the wheel is

flush with the hub surface.

18. Put the coarse feed handle on the feed shaft and

tap it lightly until its roll pin engages a hole in the

hub and it is flush against the hub surface.

19. Unwrap and clean the knee crank and install it on

its shaft.

20. Install the rubber way covers at front and behind

the table.

Summary of Contents for JTM-4VS

Page 10: ...10 JTM 4VS Dimensions Figure 2 Installation Diagram...

Page 11: ...11 JTM 4VS Overview and Terminology Figure 3 Overview...

Page 26: ...26 Head Assembly...

Page 30: ...30 Spindle Assembly...

Page 34: ...34 Base Assembly...