10

6.13

Wheel balancing

With the grinder

unplugged from the power

source

, and arbor nuts snugged down, rotate

wheels by hand and observe their motion.

A grinding wheel has proper balance when:

1. The wheel’s outside face spins true and round;

that is, its circumference rotates concentric to

the arbor.

2. There is no side-to-side wobble.

The operator who takes time to patiently perform

needed adjustments will be rewarded by wheels

running true, and accurate grinding of work pieces.

6.13.1

Adjusting concentricity

If the outside face is not rotating concentric to

arbor, try shifting the wheel closer to arbor

centerline before tightening the nut. See A, Figure

6.

Another method of achieving concentricity is the

use of a wheel dresser (not provided). “Dressing” is

the removal of the current layer of abrasive to

expose a fresh surface. A wheel dresser is also

used to “true” a wheel; that is, to make the grinding

surface parallel to the tool rest, so the entire wheel

presents an even surface to the work piece. Proper

use of a wheel dresser will eliminate high spots

and result in concentric rotation about the arbor, as

well as minimize vibration. (Always follow the

wheel dresser manufacturer’s instructions.)

Figure 6: wheel balancing

6.13.2

Correcting side-to-side wobble

1. Loosen nut and rotate the outer flange a little.

Snug the nut and spin the wheel by hand to

check.

2. If wobble still exists, continue repeating step 1,

rotating outer flange incrementally in the same

direction. See B, Figure 6. Make sure to keep

the wheel in the same position each time.

3. If complete rotation of outer flange has proved

ineffective, remove nut, outer flange, and

wheel (keep wheel in same orientation by

placing a pencil mark on it somewhere for

reference). Then rotate inner flange about 90°

and repeat the above steps for the outer

flange.

4.

Continue this combination of flange

movements until the wobble is eliminated.

If required, a shim made of thick paper or card

stock may be placed between flange and wheel

side.

NOTE: Very slight wobble may still exist at spin-up

and spin-down, but will not affect normal speed

operation.

If excessive wobble still exists after performing the

above remedies, consult

section 12.0

for further

possibilities. When troubleshooting, keep in mind

these possible sources of imbalance:

1. Wheel not concentric.

2. Wheel wobbles side-to-side.

3. Wheel arbor bushing has play in it.

4. Wheel is poor quality.

5. Flanges are warped.

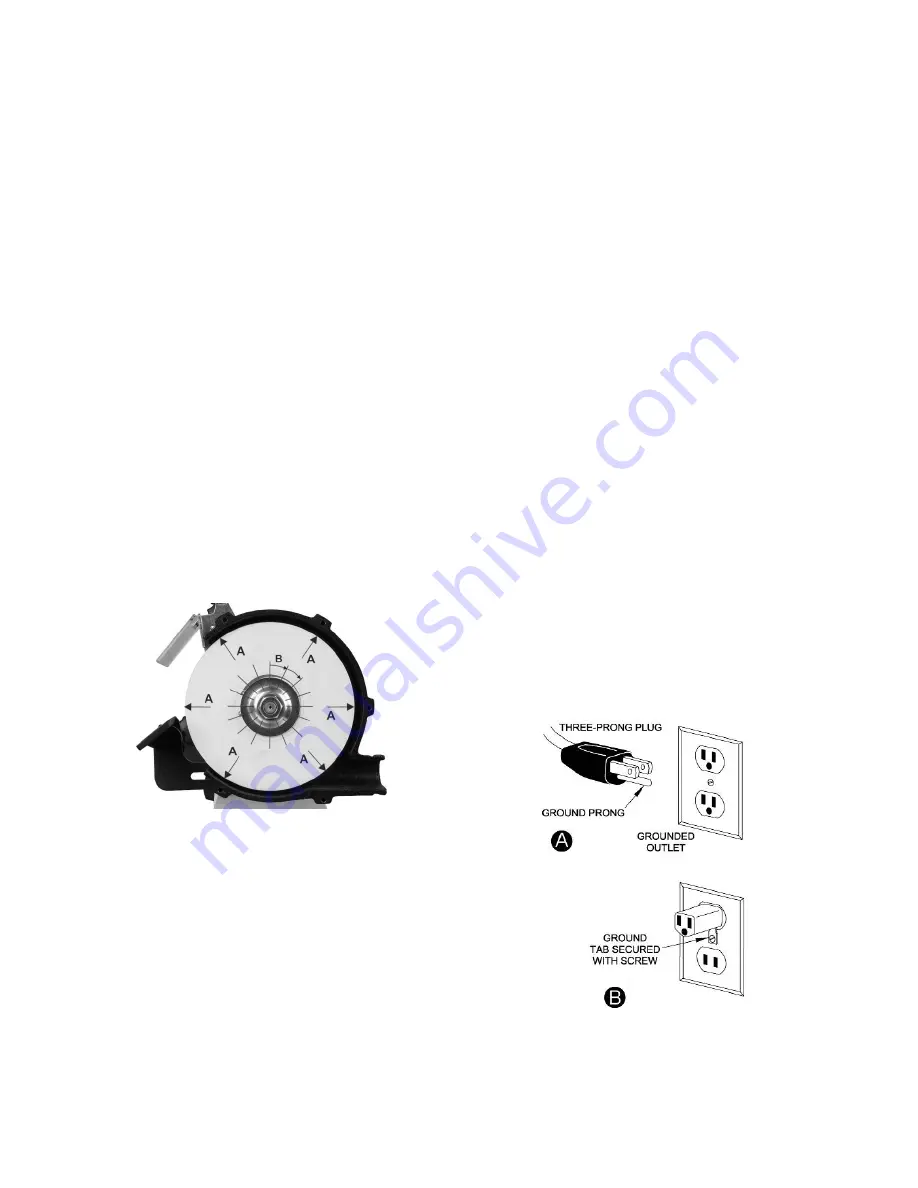

7.0

Electrical connections

The JWBG-8 Bench Grinder is rated at 115 volt

power. The grinder is supplied with a plug

designed for use on a circuit with a 110-120V

grounded outlet

that looks like the one pictured in

A, Figure 7.

Before connecting to power source, be sure switch

is in

off

position.

It is recommended the grinder be connected to a

15 amp circuit with a 15 amp circuit breaker or

time-delay fuse marked “D”.

Local codes take

precedence over recommendations.

Figure 7: plug and receptacle