12

8.3

Tool rest adjustment

As the wheel wears down, the tool rest must be re-

adjusted to maintain a 1/16" to 1/8” distance.

1. Loosen two hex cap screws (H, Figure 8) with

a 12mm wrench.

2. Slide tool rest bracket (Q) as needed.

3. Tighten

screws

(H).

9.0

Operation

A bench grinder is designed for hand-grinding

operations such as sharpening chisels,

screwdrivers, drill bits, removing excess metal, and

smoothing metal surfaces.

A

Medium Grain Abrasive Grinding Wheel

is

suitable for rough grinding where a considerable

amount of metal must be removed or when

obtaining a smooth finish is not important.

A

Fine Grain Abrasive Grinding Wheel

should be

used for sharpening tools to close size tolerances

because it removes metal more gradually for

precision grinding and gives work a smooth finish.

Do not operate this grinder

without all guards and shields in place and in

working order. Always use approved safety

glasses or face shields. Failure to comply may

cause serious injury.

9.1

Switch

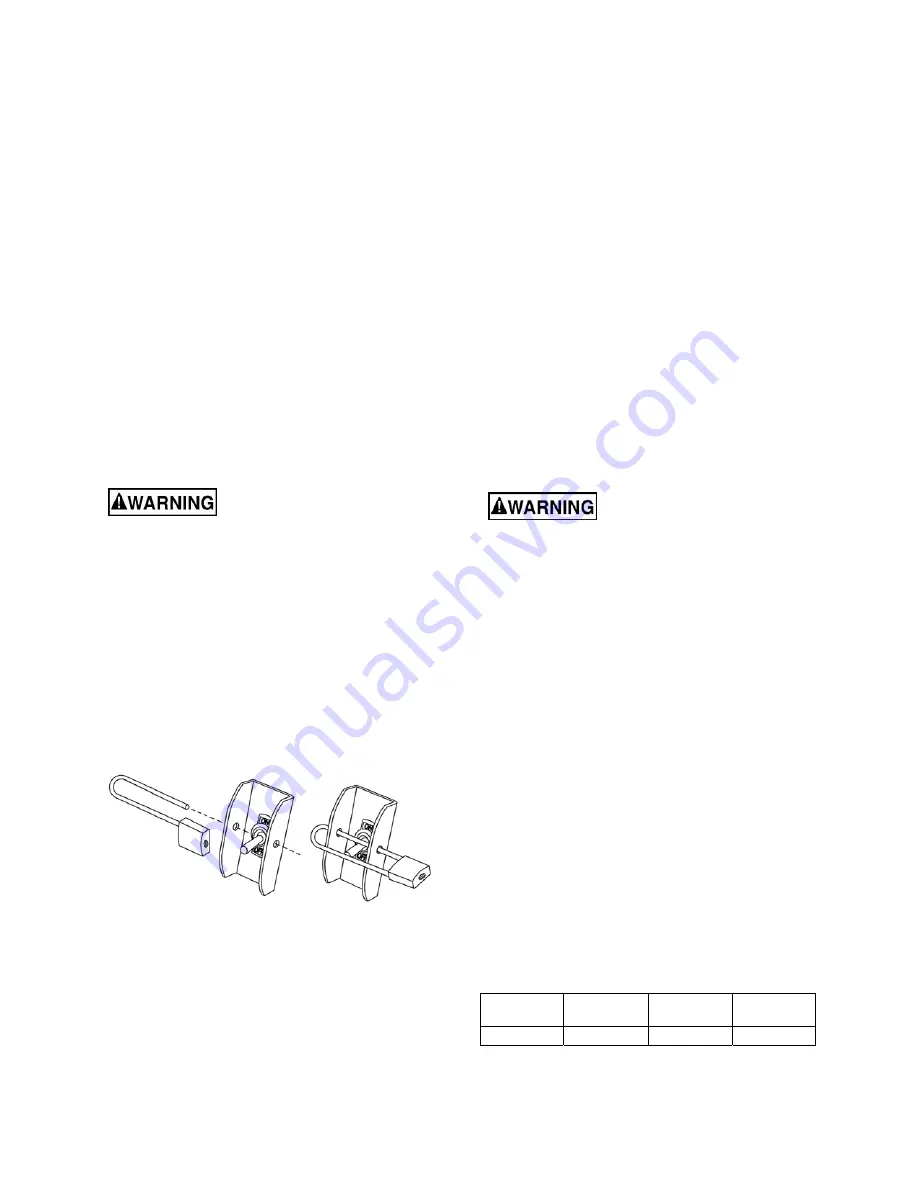

The toggle switch guard will accept a padlock, as

shown in Figure 9. To safeguard the grinder from

unauthorized operation and accidental starting by

young children, use of a padlock (not provided) is

highly recommended. Place the key in a location

inaccessible to children and others not qualified to

use the tool.

Figure 9 – switch lockout (padlock not provided)

9.2

Precautions

Before starting the grinder, turn the wheels by hand

to verify they are clear of obstructions and will turn

freely. Tool rests and spark guards should not

touch the wheel.

Adjust spark arrestor, eye shield, and tool rest into

proper positions. Stand to one side of the wheel

paths, and turn on the grinder. Allow it to reach full

running speed before beginning operation.

Keep a steady, moderate pressure on the

workpiece and keep it moving at an even pace for

smooth grinding. Pressing too hard overheats the

motor and prematurely wears down the grinding

wheels. Note the original bevel angle on the item to

be sharpened and try to maintain the same shape.

The tilt scale on the tool rest will aid in establishing

this angle. The grinding wheel should rotate into

the object being sharpened. Keep a tray filled with

water and dip your work into it regularly to prevent

overheating. Overheating can weaken metals.

Do not use the side of the grinding wheel; this puts

dangerous stress on the wheel.

When the wheel becomes loaded or dull, use an

approved grinding wheel dresser and dress the

wheel face.

Keep tool rest and spark guard to within 1/16" of

the grinding wheel. See

Adjustment

section to

adjust.

10.0

Maintenance

Always disconnect power to

the machine before performing maintenance.

Failure to do this may result in personal injury.

For safety, turn the switch to OFF and remove plug

from the power source outlet before adjusting or

servicing the bench grinder. If the power cord is

worn, cut or damaged in any way, have it replaced

immediately.

10.1

Care of grinding wheels

In normal use, grinding wheels may become

cracked, grooved, rounded at the edges, chipped,

out of true or loaded with foreign material.

Cracked wheels should be replaced

immediately

.

While any of the other conditions can be remedied

with a dressing tool (available at most hardware

stores), new wheels sometimes require dressing to

make them round.

10.2

Changing wheels

If you must replace a wheel be sure to obtain one

with a safe rated speed at least as high as the

NO

LOAD RPM

marked on the grinder's nameplate.

Table 2 shows correct dimensions for the

replacement wheel.

Wheel

Diameter

Maximum

width

Center

hole

JWBG-8 8”

3/4" 5/8”

Table 2