15

7. Guide new blade through table slot. Place

blade in upper and lower blade guides.

Note:

The blade teeth should face the operator,

and they should point down toward the table.

8. Place blade in the middle of the upper and

lower wheel.

9. Re-install table insert (B) and table pin (C).

10. Tension and track blade before operating saw.

Find instructions for tensioning and tracking the

blade in the

Adjusting Blade Tension

and

Adjusting Blade Tracking

sections.

Adjusting Blade Tension

1. Disconnect machine from power source.

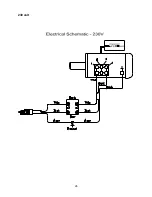

2. Turn blade tension knob (Figure 17) clockwise

to tension blade.

3. Apply just enough tension to take the slack out

of the blade.

4. Turn one wheel a few times to move the blade

to the center of the tire

5. With a meter, tension the blade appropriately

for the size of blade used.

6. A gauge (Figure 17) on the upper wheel slide

bracket indicates the approximate tension

according to the width of the blade. Initially, set

the blade tension to correspond to the blade

width as marked on the gauge.

Note 1:

As you become more experienced with the

saw, you may find it necessary to change the blade

tension from the initial setting. Changes in blade

width and the type of material being cut will have

an effect on blade tension.

Note 2:

Keep in mind that too little or too much

blade tension can cause blade breakage.

Adjusting Blade Tracking

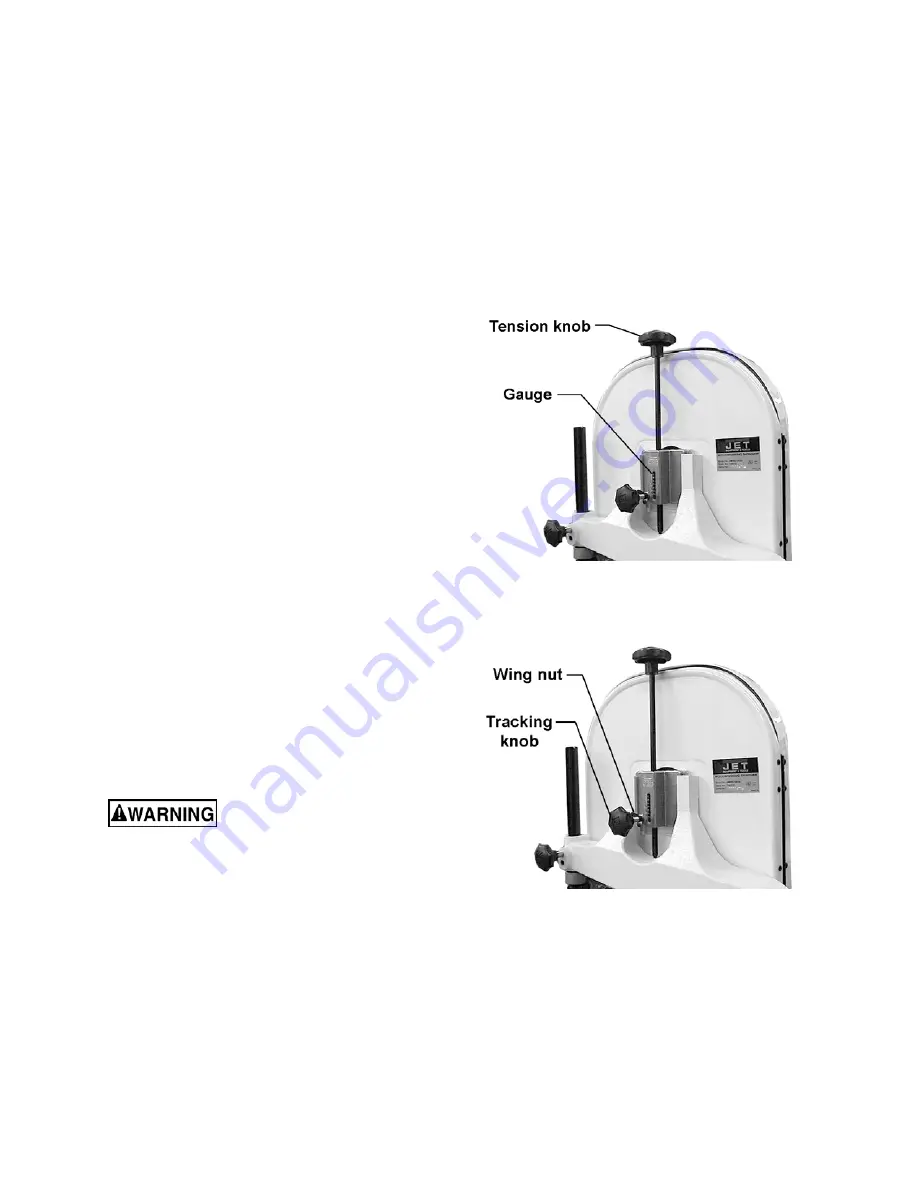

Disconnect machine from the

power source! Never adjust blade tracking with

the machine running! Failure to comply may

cause serious injury!

Tracking

refers to how the blade is situated upon

the wheels while in motion. The blade should track

in the center of both wheels.

The blade must be properly tensioned before

adjusting blade tracking. Make sure blade guides

and blade bearings do not interfere with the blade.

1. Open the top wheel cover. Rotate the wheel

forward by hand, and observe the position of

the blade on the wheel. It should be in the

center of the wheel.

Figure 17

Figure 18

2. If adjustment is necessary, loosen wing nut

(Figure 18). Tightening the tracking knob

slightly will move blade so it tracks towards the

rear of machine. Loosening the tracking knob

slightly will cause the blade to track toward the

front of the machine.

3. After blade is tracking in the center of the

wheel, tighten the wing nut.

Summary of Contents for JWBS-140S

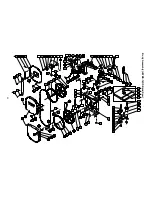

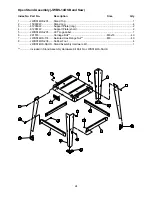

Page 23: ...23 Body Assembly JWBS 14OS Band Saw...

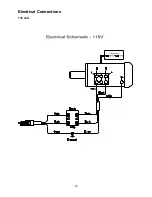

Page 25: ...25 Electrical Connections 115 volt...

Page 26: ...26 230 volt...

Page 27: ...27 Notes...