19

Troubleshooting JWBS-14OS Band Saw

Trouble Probable

Cause

Remedy

Saw unplugged.

Check all plug connections.

Fuse blown, or circuit breaker tripped. Replace fuse, or reset circuit breaker.

Saw stops or will not

start.

Cord damaged.

Replace cord.

Table stop not adjusted correctly.

Check blade with square and adjust

table stop.

Angle pointer not set accurately.

Check blade with square and adjust

pointer.

Does not make

accurate 45 or 90

degree cuts.

Miter gauge out of adjustment.

Adjust miter gauge.

Fence not aligned with blade.

Check and adjust fence (see fence

manual).

Warped wood.

Select another piece of wood.

Excessive feed rate.

Reduce feed rate.

Incorrect blade for cut.

Change blade to correct type.

Blade tension not set properly.

Set blade tension according to blade

size.

Blade wanders during

cut.

Guides not set properly.

Adjust guides.

Dull blade.

Replace blade.

Blade mounted wrong.

Teeth should face operator and point

downward.

Gum or pitch on blade.

Remove blade and clean with oven

cleaner or other solvent.

Incorrect blade for cut.

Change blade to correct type.

Saw makes

unsatisfactory cuts.

Gum or pitch on table.

Clean table.

Extension cord too light or too long.

Replace with adequate size and

length cord.

Blade does not come

up to speed.

Low shop voltage.

Contact your local electric company.

Base on uneven floor.

Reposition on flat, level surface.

Saw vibrates

excessively.

Loose fasteners.

Tighten fasteners.

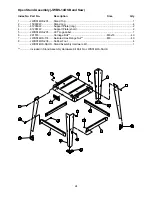

Parts

Ordering Replacement Parts

To order parts or reach our service department, call 1-800-274-6848 between 7:30am and 6:00pm (CST),

Monday through Friday. Having the Model Number and Serial Number of your machine available when

you call will allow us to serve you quickly and accurately.

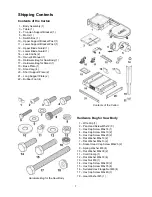

Summary of Contents for JWBS-140S

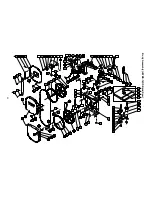

Page 23: ...23 Body Assembly JWBS 14OS Band Saw...

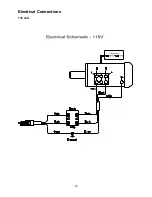

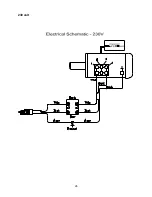

Page 25: ...25 Electrical Connections 115 volt...

Page 26: ...26 230 volt...

Page 27: ...27 Notes...