16

12.0

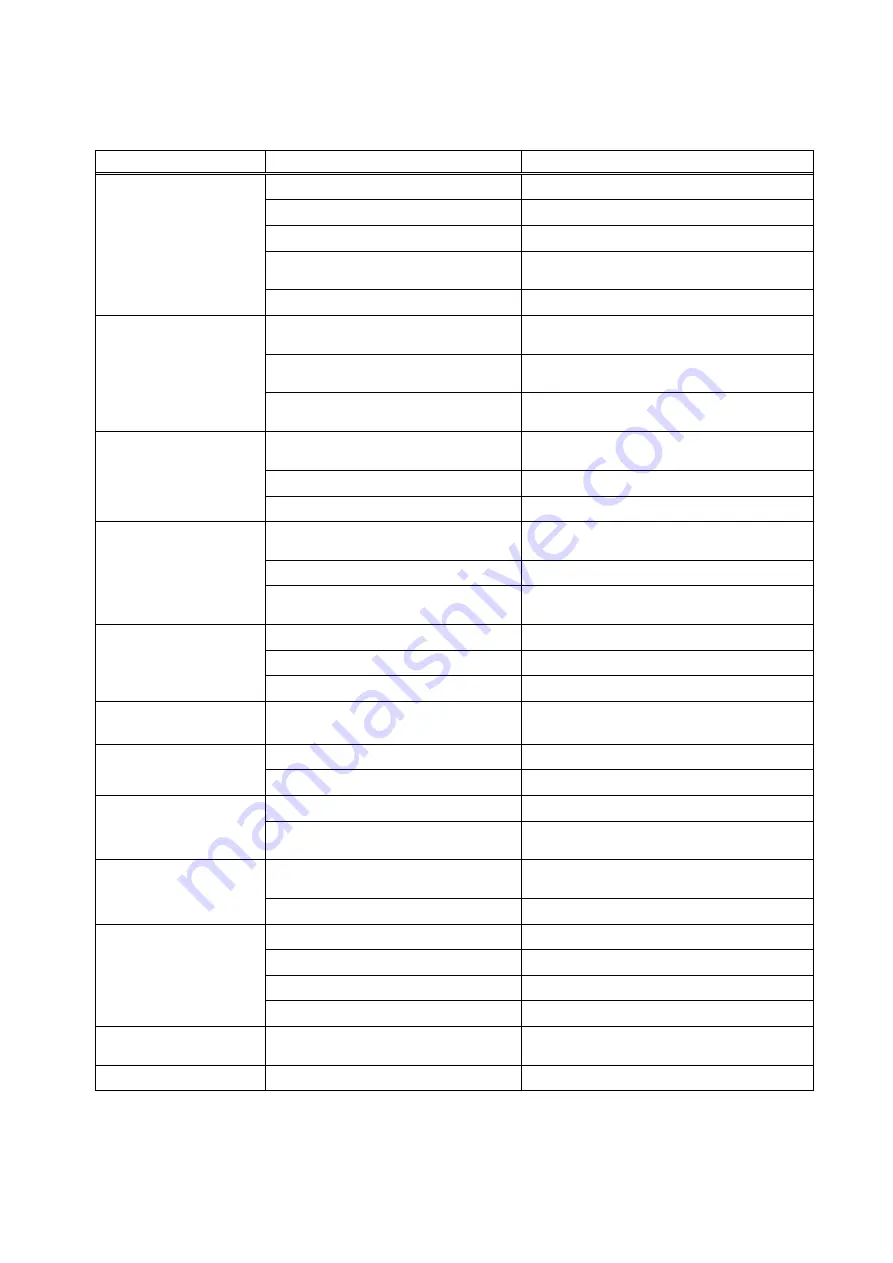

Troubleshooting JWDS‐1020‐M Drum Sander

Symptom

Possible Cause

Correction *

Drum motor won’t start

when switch is activated.

No incoming current.

Check connections at plug or circuit panel.

Safety key missing from switch.

Install safety key.

Low voltage.

Check power line for proper voltage.

Open circuit in motor or loose connection. Inspect all lead connections on motor for loose

or open connections.

Switch malfunction.

Replace switch.

Drum motor will not start:

fuses blow or circuit

breakers trip.

Short circuit in line cord or plug.

Inspect cord or plug for damaged insulation and

shorted wires.

Short circuit in motor or loose

connections.

Inspect all connections on motor for loose or

shorted terminals or worn insulation.

Incorrect fuse or circuit breaker in power

line.

Install correct fuse or circuit breaker.

Drum motor overheats.

Air circulation through motor restricted.

Clean motor fan with compressed air to restore

normal air circulation.

Motor overloaded, excess feed rate.

Reduce conveyor speed.

Motor overloaded, excess depth of cut.

Reduce depth of cut.

Drum motor stalls,

resulting in blown fuses or

tripped circuit.

Short circuit in motor or loose

connections.

Inspect connections on motor for loose or

shorted terminals or worn insulation.

Low voltage.

Correct low voltage conditions.

Incorrect fuse or circuit breaker in power

line.

Install correct fuse or circuit breaker.

Loud, repetitive noise or

vibration coming from

machine.

Fasteners loose.

Inspect fasteners and tighten where needed.

Motor fan is hitting cover.

Tighten fan or shim fan cover.

Machine not level.

Place sander on flat surface, shim if needed.

Conveyor motor stalls.

Excessive depth of cut.

Reduce depth of cut; use coarser grit; reduce

feed rate.

Conveyor belt slips on drive

roller.

Improper conveyor belt tension.

Adjust belt tension.

Excessive depth of cut and/or feed rate.

Reduce depth of cut and/or feed rate.

Abrasive strip comes off

drum.

Slack in abrasive strip on drum.

Remove slack in strip.

Abrasive improperly wrapped.

Read the section on installing abrasives, and

rewrap.

Abrasive strip is loose.

Strip caught on inside edge of slot, or on

inboard side of drum.

Re‐adjust the strip end in the slot and/or trim

the abrasive edge.

Strip not cut properly.

Re‐cut and re‐install the abrasive strip.

Abrasive loads up

prematurely.

Excessive depth of cut.

Reduce depth of cut.

Excessive feed rate.

Reduce feed rate.

Inadequate dust collection.

Increase airflow at dust port.

Inadequate abrasive.

Use an open‐coat abrasive.

Line or groove in stock.

Inconsistent feed rate.

Do not stop or change the feed rate while

feeding stock.

Snipe marks.

Improper tension on rollers.

Re‐tension rollers.