8

6.3

Handle

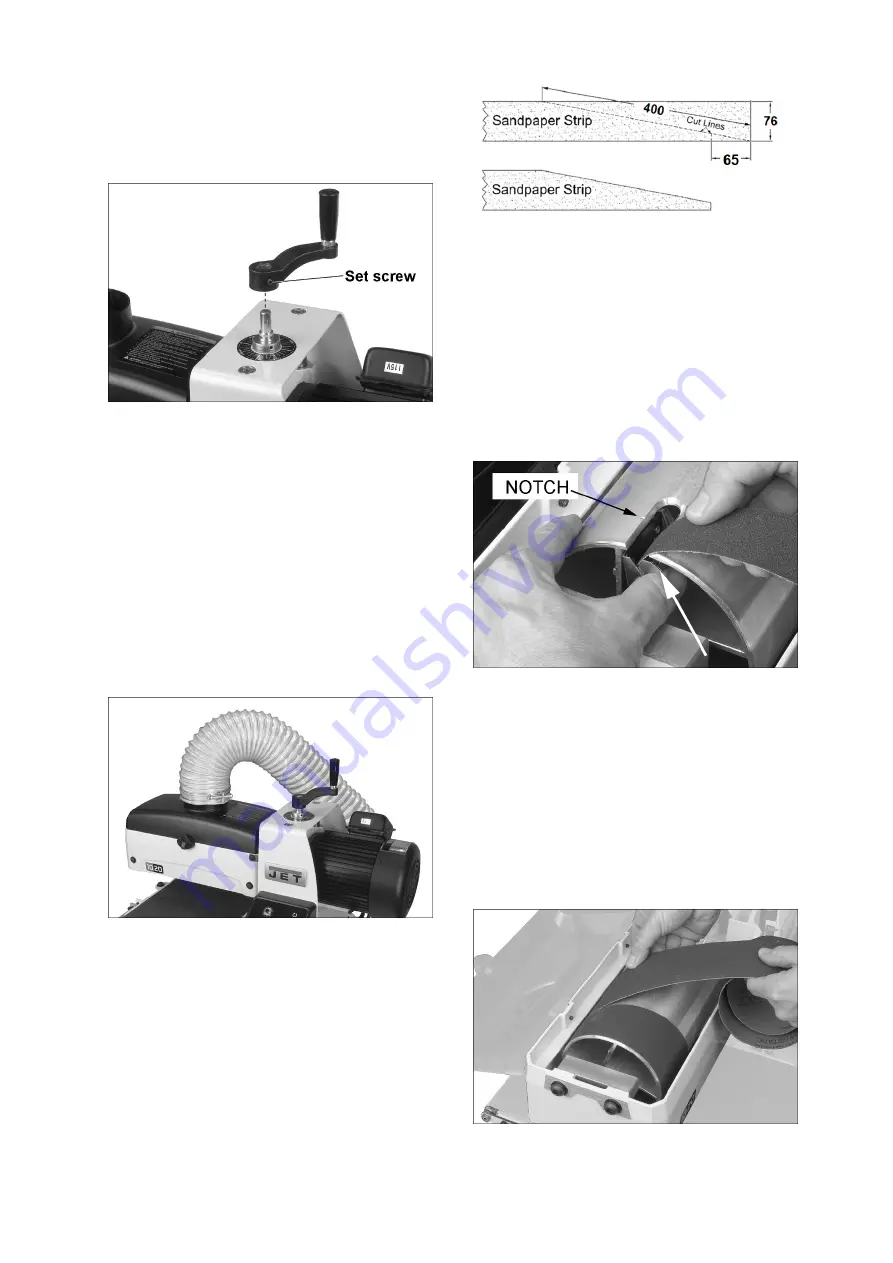

Install handle onto elevating screw, aligning flat in

handle shaft with flat on elevating screw. Tighten set

screw with 3mm hex wrench to secure handle.

Figure 6‐1: installing handle

6.4

Mounting to workbench

The sander should be bolted to a workbench or table

to avoid any tendency to creep or slide during

sanding operations. Use appropriate fasteners (not

provided) through the 4 slots in the machine base.

6.5

Dust collection

Dust collection is mandatory for a safe work

environment and extended abrasive life. The JWDS‐

1020 is equipped with a 100mm dust collection port.

Secure a 100mm dust collection hose (not provided)

to the port with a hose clamp (see Figure 6‐2).

Connect to a high volume dust collector, minimum

560m

3

/h.

Figure 6‐2 (hose and clamp not included)

6.6

Installing abrasives

Proper attachment of the abrasive strip to the drum

is critical to achieving top performance from your

drum sander.

An 80‐grit, 76mm wide abrasive strip is pre‐installed

on the drum.

(TIP: If you are using an after‐market abrasive, use a

new JET‐supplied abrasive as a template to quickly

cut a new strip.

Figure 6‐3: abrasive trimming

1.

Rotate hood latch counter clockwise to open.

2.

Press fastener lever (Figure 6‐4) on outboard

(left) end of drum, and insert tapered end of

abrasive through slit in fastener, as shown. Align

tapered edge of abrasive strip with left edge of

drum. Insert enough strip so that the right edge

aligns with the reference notch; this will ensure

the proper length of strip to be secured at the

opposite end of the drum.

Figure 6‐4

3.

Release fastener lever to secure end of strip.

4.

Begin wrapping abrasive around drum. The

tapered edge of strip end should follow as

closely as possible to edge of drum.

5.

Continue to wrap abrasive in spiral fashion by

rotating drum with one hand and guiding strip

with the other. See Figure 6‐5.

Successive windings of strip must

not have any

overlap.

They should be flush with previous

windings or with a slight gap between.

Figure 6‐5