9

5. Position sander atop stand so that the four

threaded holes of base align with holes in the

stand rails (Figure 6).

6. Fasten base to stand (from beneath) with the

four screws and washers that you removed

from the plywood boards. Tighten screws

securely.

6.5

Infeed and outfeed tables

(optional accessory)

The sander must be bolted to the stand or a work

table when using these table extensions. Maximum

working load of each table is 35 pounds. Fasteners

are provided with the extension tables.

1. Install infeed and outfeed brackets (L, Figure 6-

3) to the threaded holes in sander base with

M8x16 socket head cap screws and flat

washers. Make sure left and right brackets are

oriented as shown. The brackets should be

flush against the base. NOTE: Long brackets

mount to front (infeed); short brackets to rear

(outfeed).

2. Place extension tables over brackets and

secure with M8x12 socket head cap screws and

washers.

Finger tighten only.

3. Position tables slightly below conveyor belt

surface for proper support of stock. To check

position, place a straight-edge on one side of

conveyor table under drum and extending out

over the extension table. Lower drum to

securely hold straight-edge in place. See Figure

6-4. Raise infeed/outfeed table until table

surface is slightly below conveyor belt surface.

Tighten screws on that side.

4. Reposition straight-edge to other side of table

and repeat.

If stock being sanded is bowed, warped or otherwise

inconsistent, be sure tables are lower than top of

conveyor table.

If stock slips on conveyor, the tables may be

positioned too high. Lower tables to allow stock to

remain in contact with conveyor.

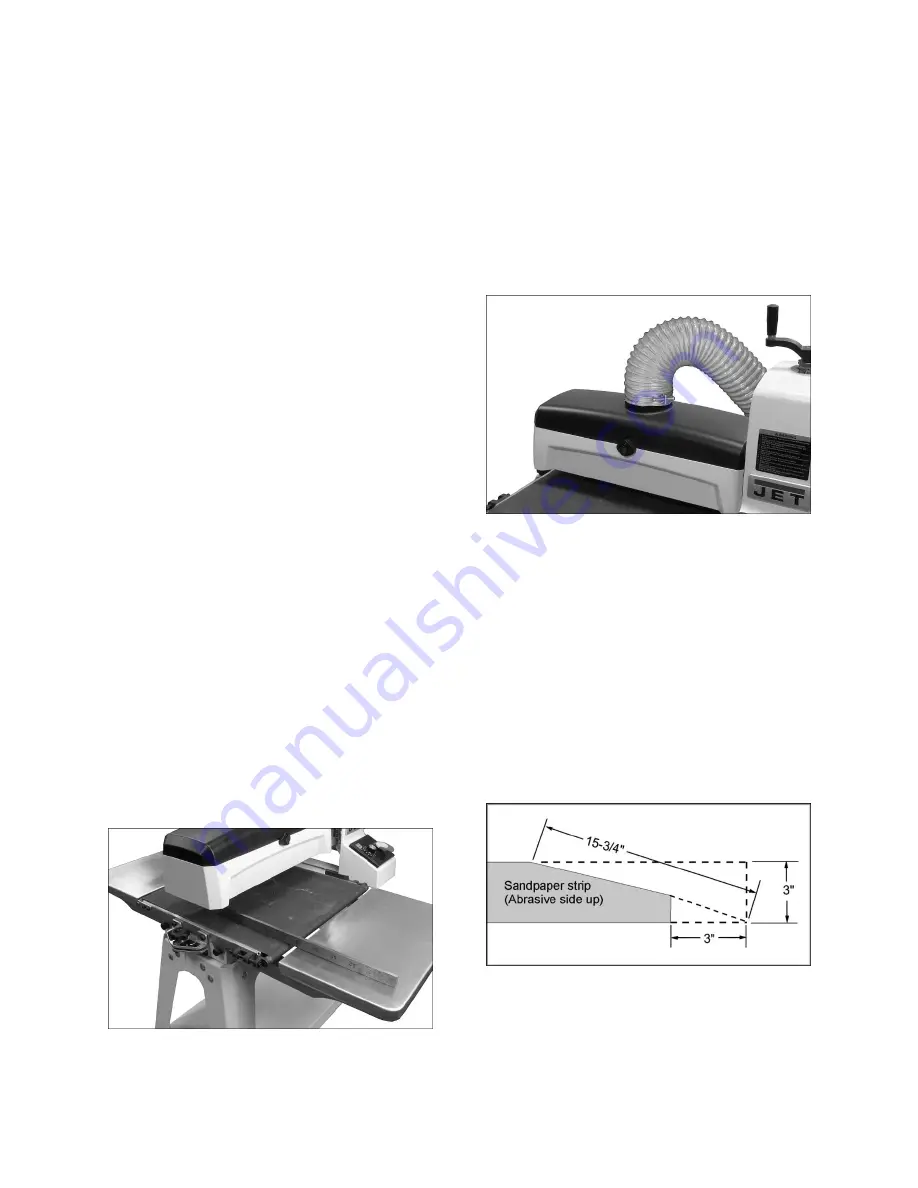

Figure 6-4: extension table alignment

6.6

Dust collection

Dust collection is mandatory for a safe work

environment and extended abrasive life. The

JWDS-1632/1836 is equipped with a 4-inch dust

collection port. Secure a 4-inch dust collection hose

to the port with a hose clamp (Figure 6-5), and

connect to a high volume dust collector (minimum

400 CFM).

Note: Dryer vent hose is not acceptable

for this purpose.

A standard shop type canister (16 gal. or larger) can

be used for short periods of sanding time but

requires converting the hose size down to 2-1/2”. An

adaptor is required.

Figure 6-5 (hose and clamp not included)

6.7

Installing abrasives

Proper attachment of the abrasive strip to the drum

is critical to achieving top performance from your

drum sander.

An 80-grit, 3-inch wide abrasive strip is pre-installed

on the drum. Optional pre-cut (“Ready-to-Wrap”)

abrasives of different grits are also available; see

sect. 14.0

.

(TIP: If you are using an after-market abrasive, use

a new JET-supplied abrasive as a template to

quickly cut a new strip. Alternatively, a diagram is

supplied in Figures 6-6 and 6-7 showing trim

measurements.)

Figure 6-6: abrasive trimming –

JWDS-1632 ONLY

(not applicable to Ready-to-Wrap strips)