14

11.2

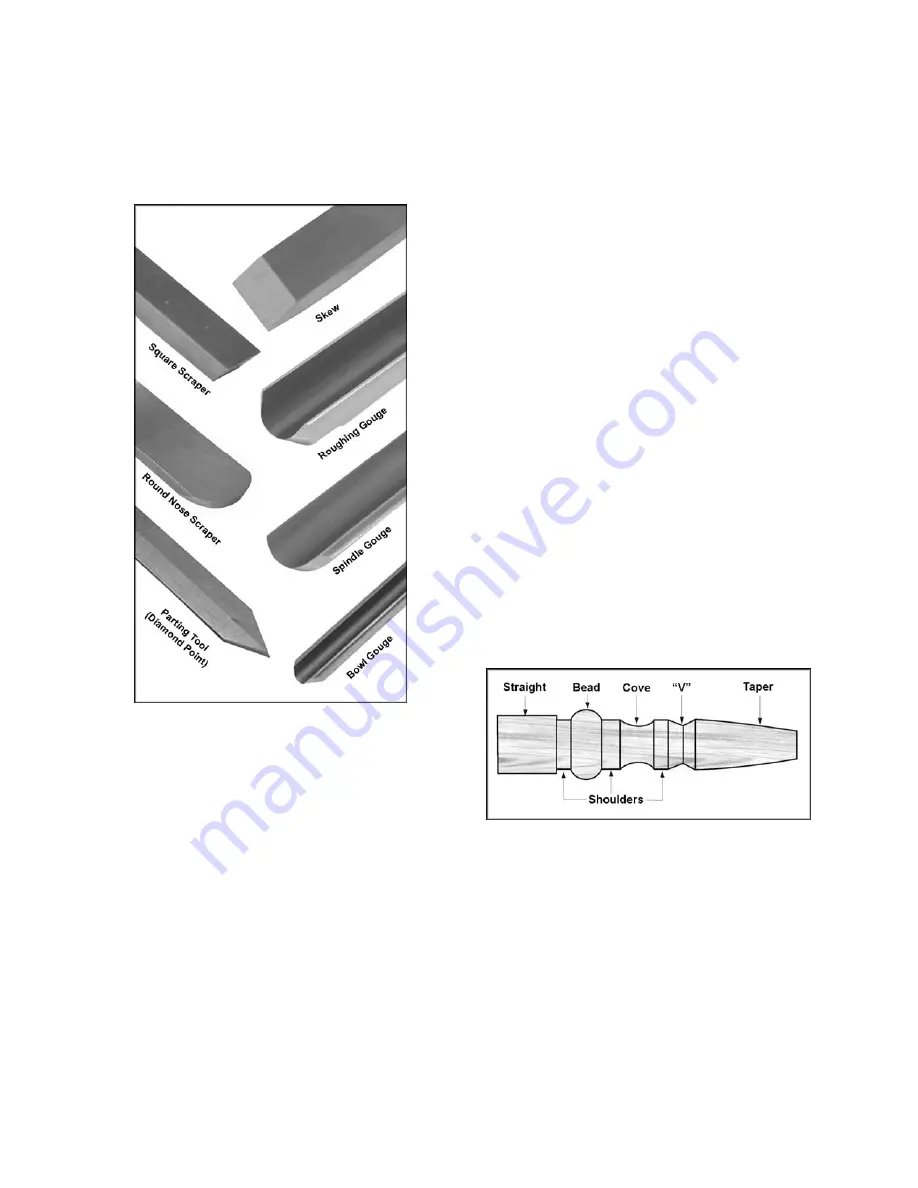

Turning Tools

If possible, select only quality, high-speed steel

turning tools. High-speed steel tools hold an edge

and last longer than ordinary carbon steel. As one

becomes proficient in turning, a variety of specialty

tools for specific applications can be acquired. The

following tools provide the basics for most

woodturning projects (see Figure 18):

Figure 18

Basic Turning Tools

Skews

– 1-1/2" and 1" or 1-1/4", used to make

finishing cuts and details.

Large Roughing Gouge

– 1" to 1-1/4", used to

eliminate waste wood.

Spindle Gouges

– 1/4", 3/8", 1/2", used to turn

beads, coves and other details.

Deep Fluted Bowl Gouge

– 1/4", 3/8" and 1/2",

used for turning bowls & plates.

Square Scraper (Bedan)

– 3/8” or 1/2", used to

create square shoulders.

Large Round Nose (Domed) Scraper

– 1-1/2",

used to reduce ridges on interior of bowls, round

edges of bowls, etc.

Parting Tool

- 1/8", used for scraping, making a

cut-off, or to set diameters for sizing.

For safety and best performance,

keep tools sharp

.

If a tool stops cutting or requires excessive

pressure to make a cut, it needs to be sharpened.

A number of brand name sharpening jigs and

fixtures are available; however, a woodturner

should learn to sharpen tools freehand.

For best results, use a slow speed grinder (1800

rpm) fitted with a 60-grit aluminum oxide wheel (for

shaping) and a 100-grit alum. oxide wheel (for final

sharpening and touchup). The grinder should be

located near your lathe and at a comfortable

height. A diamond dresser will keep the wheels

true and eliminate glazing.

Never allow the tool to rest in one place on the

wheel, keep it moving and use a light touch.

Carbon steel tools can overheat easily and should

be cooled frequently. If the edge turns blue, it has

lost its temper and should be ground past the blue

area. High-speed steel tools are not as likely to

overheat, but can be damaged if allowed to get red

hot. High-speed steel tools should not be

quenched for cooling. Honing with a diamond lap

or slipstone will save trips to the grinder and keep

the edge fresh.

11.3

Spindle Turning

Spindle turning takes place between the centers of

the lathe. It requires a spur or drive center in the

headstock, and a live or dead center in the

tailstock. A cup center rather than a cone center in

the tailstock will often reduce the risk of splitting the

stock.

Figure 19 shows the basic profile shapes in spindle

turning.

Figure 19

11.3.1

Stock Selection

Stock for spindles should be straight grained and

free of checks, cracks, knots and other defects. It

should be cut 1/8" to 1/4" larger than the finished

diameter and may require additional length so the

ends can be removed later. Larger stock should

have the corners removed to produce an octagon

making the piece easier to rough down to a

cylinder.

1. With a combination square, or plastic center

finder for round stock, locate and mark center

on each end of the workpiece. Accuracy is not

critical on full rounds but extremely important

on stock where square sections are to remain.

Summary of Contents for JWL-1015

Page 8: ...8 6 1 Hole pattern JWL 1015 1015VS lathes Figure 2 Clearance hole spacing for mounting lathe ...

Page 26: ...26 16 2 1 JWL 1015VS Lathe Exploded View ...

Page 29: ...29 17 0 Electrical Connections JWL 1015 JWL 1015VS variable speed model LED Light MAX ...

Page 30: ...30 This page intentionally left blank ...

Page 31: ...31 This page intentionally left blank ...

Page 32: ...32 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...