14

Stock Selection

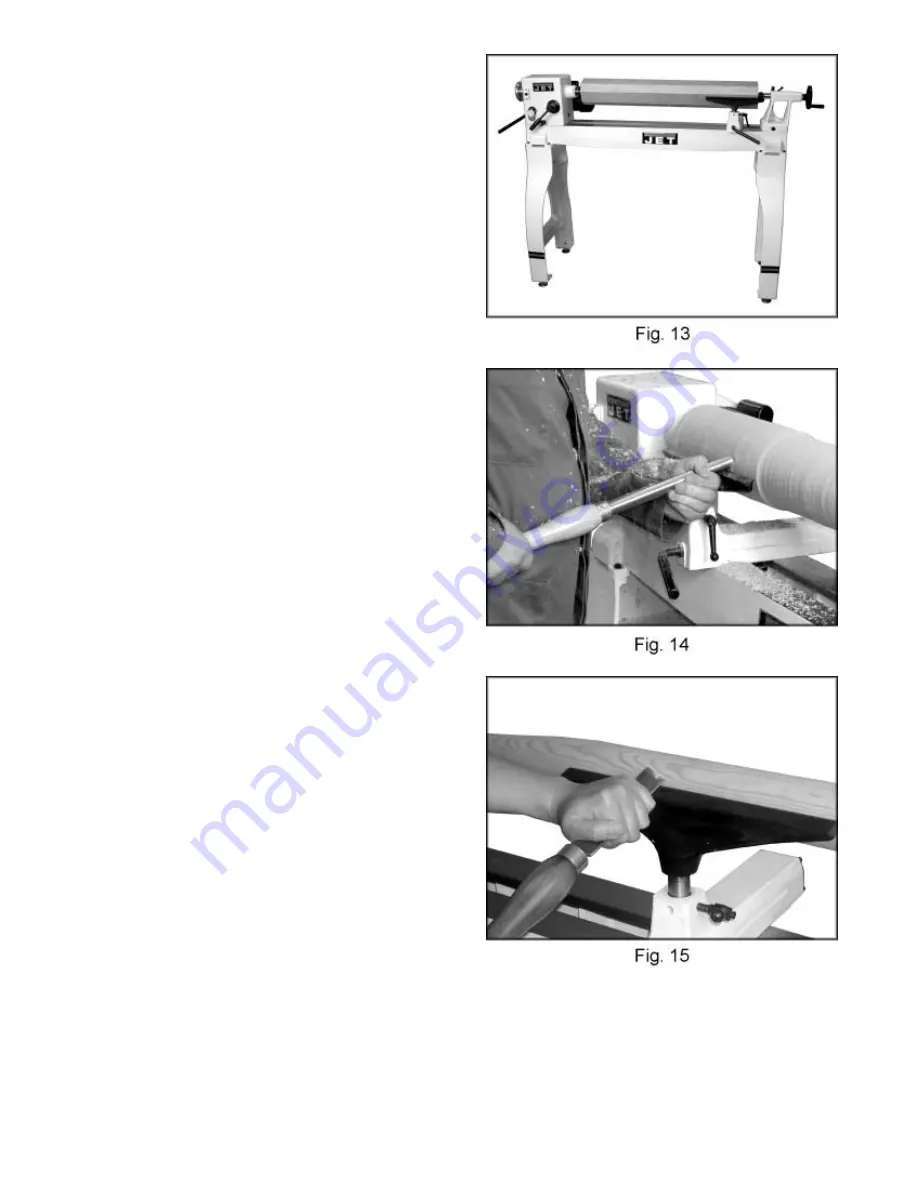

Stock for spindles should be straight grained

and free of checks, cracks, knots and other

defects. It should be cut 1/8" to 1/4" larger than

the finished diameter and may require additional

length to remove ends if required. Larger stock

should have the corners removed to produce an

octagon making the piece easier to rough down

to a cylinder, see Figure 13.

Roughing Out

1. Use a large roughing gouge and begin

cutting about 2” from the tailstock end of the

workpiece. Place the tool on the tool rest

with the heel of the tool on the surface to be

cut.

2. Slowly and gently raise tool handle until

cutting edge comes into contact with the

workpiece. Work to the right towards the

end of the workpiece. You never want to

start at the end of a workpiece.

3. Now continue to work the rest of the

workpiece. Roll the flute (hollowed-out

portion) of the tool in the direction of the cut,

see Figure 14. Make long sweeping cuts in

a continuous motion to rough the piece

down to a cylinder. Keep as much of the

bevel of the tool as possible in contact with

the workpiece to ensure control and avoid

catches. Note: Always cut downhill, or

from large diameter to small diameter.

Always work toward the end of a workpiece,

never start cutting at the end.

4. Once the workpiece is roughed down to a

cylinder, smooth it with a large skew. Place

the cutting point near the center of the chisel

and high on the workpiece, see Figure 15.

Touching one of the points of the skew to

the spinning workpiece may cause a catch

and ruin the workpiece.

5. Add details to the workpiece with skew,

spindle gouge, etc.

Summary of Contents for JWL-1442VS

Page 22: ...22 Bed Assembly...

Page 24: ...24 Headstock Assembly...

Page 28: ...28 Wiring Diagram...