4

24. Check centers and center sockets in the headstock and tailstock to be sure they are free of dirt or rust

and oil lightly before inserting centers.

25. Test each set-up by revolving the work by hand to insure it clears the tool rest and bed. Check setup

at the lowest speed before increasing it to the operating speed.

26. Use the correct cutting tool for the operation to be performed and keep all tools in a sharpened

condition.

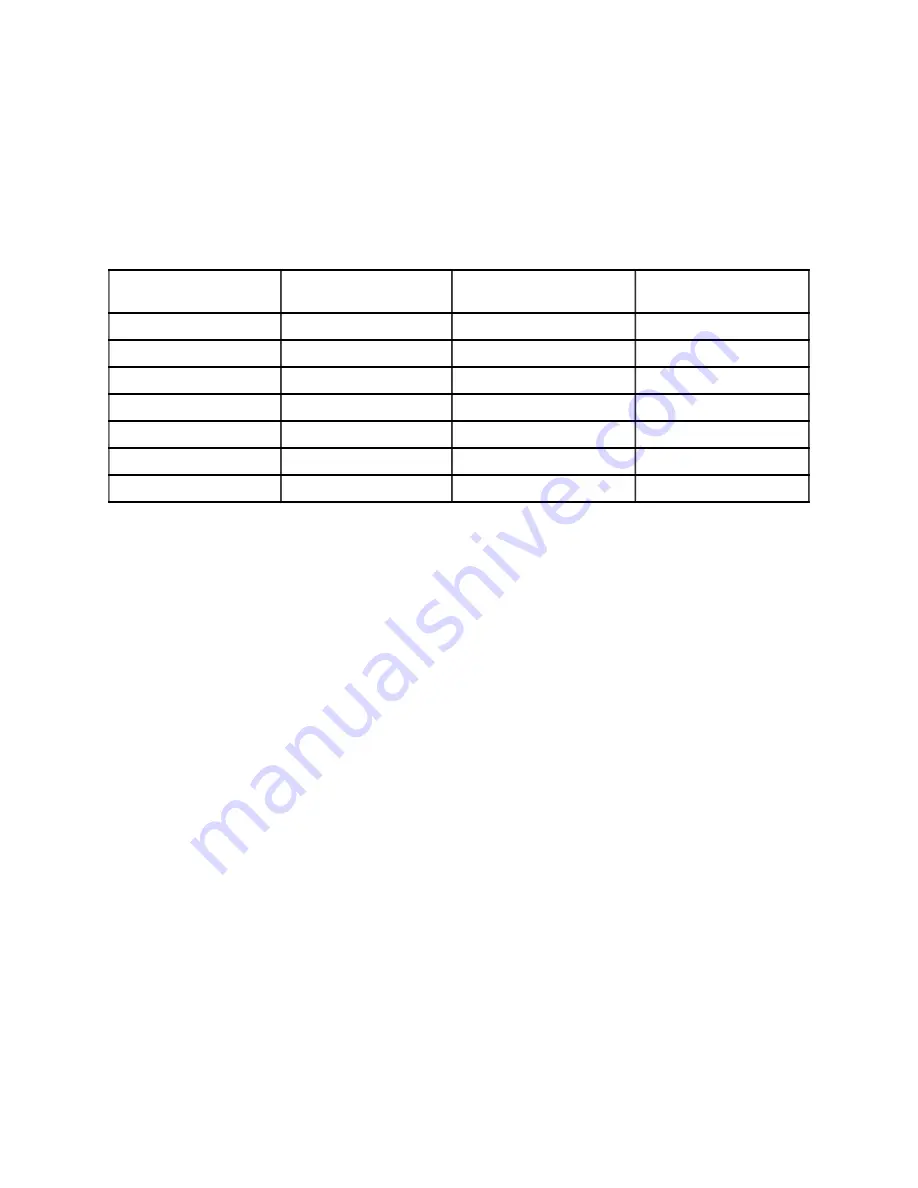

27. Use low speeds for roughing and for long or large diameter work. If vibration occurs, stop the

machine and correct the cause. See speed recommendations.

Diameter of Work

Roughing RPM

General Cutting RPM

Finishing RPM

Under 2"

1500

3000

3000

2 to 4"

600

1500

2300

4 to 6"

450

1100

1500

6 to 8"

450

600

1100

8 to 10"

450

600

850

10 to 12"

450

600

850

12 to 14"

450

450

600

28. When sanding, remove the tool rest from the machine, apply light pressure, and use a slow speed to

avoid heat build up.

29. When turning large diameter pieces, such as bowls, always operate the lathe at low speeds. See

speed recommendations.

30. Do not attempt to engage the spindle lock pin until the spindle has stopped. If leaving the machine

area, turn it off and wait until the spindle stops before departing.

31. Make no adjustments except speed change with the spindle rotating and always disconnect machine

from power source when performing maintenance to avoid accidental starting or electrical shock.

32. Provide for adequate surrounding work space and overhead non-glare lighting.

33. When stopping the lathe, never grab the part or face plate to slow it down. Let the work coast to a

stop.

34. Use only JET factory authorized replacement parts and accessories; otherwise the warranty and

guarantee are null and void.

35. Do not use this JET wood lathe for other than its intended use. If used for other purposes, JET

disclaims any real or implied warranty and holds itself harmless from any injury that may result from

that use.

Summary of Contents for JWL-1442VS

Page 22: ...22 Bed Assembly...

Page 24: ...24 Headstock Assembly...

Page 28: ...28 Wiring Diagram...