Try to make one, very light continuous movement from the

rim to the bottom of the bowl to ensure a clean, sweeping

curve through the workpiece.

Move tool support to the exterior to re-define bottom of bowl.

6.6 Sanding and Finishing:

Remove the tool rest and begin with a fine grit sandpaper

(120 grit) and progress through each grit, using only light

pressure.

Use power sanding techniques to avoid concentric sanding

marks.

Finish sanding with 220 grit.

Apply first coat of finish. Allow to dry before sanding again

with 320 or 400 grit sandpaper.

Turn lathe back on and make a separation cut through the

base. Stop at about dia. 80mm and use a fine tooth saw to

separate the bowl from the waste.

Apply additional finish coats and allow to dry before buffing.

7. Setup and adjustments

General note:

Setup and adjustment work may only be carried out after

the machine is protected against accidental starting by

pulling the mains plug.

7.1 Changing spindle speeds

Never change speeds without the motor running. Damage to

the variable speed pulleys may result.

Disconnect lathe from power source.

To change speed range, open access door on headstock.

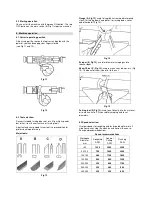

Loosen pivot lock handle (A, Figure 26) and lift up tension

handle (B) to raise motor. Tighten pivot lock handle (A) to

hold motor in raised position.

There should be sufficient slack in the belt to reposition it

to the other steps on the sheaves. The label on access

door shows required belt position (also shown in Figure

26-1).

Loosen pivot lock handle (A) and lower motor to tension

belt. Be sure that Poly-V grooves of belt seat properly in

corresponding groove of sheave. Do not over-tension; a

very light pressure on tension handle (B) is adequate to

prevent belt slippage.

Tighten pivot lock handle (A).and close access door.

Fig 26

Fig 26-1

On/off switch ( C ):

You can start the machine with the

green ON-button. The red Off-button stops the machine.

Fig 26-2

Speed control knob (D):

Clockwise to increase,

counterclockwise to decrease. Speed is displayed as RPM

(revolutions per minute) on digital readout (E).

Forward/Reverse (F)