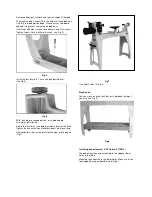

7.2 Headstock spindle lock

Push spindle lock pin (P, Figure 27) and rotate spindle

slightly until pin engages. Slide plate downward to hold pin

in locking position.

Release spindle lock by pushing plate upward.

Fig 27

Caution:

Never press the spindle lock while the spindle is turning!

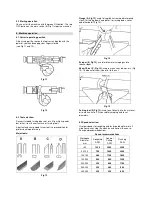

7.3 Headstock Rotation

IMPORTANT: Remove anti-rotation block (Figure 28) with

4mm hex key before attempting to rotate headstock.

Figure 28

To rotate headstock:

Loosen lock handle (A, Figure 28-1).

Unscrew knurled knob (B) counterclockwise until it can be

pulled outward.

Pull knob (B) outward and rotate headstock to desired

position. The headstock has seven positive locking

positions.

NOTE:

Be careful not to pinch your fingers

against the bed as you rotate headstock.

Release knob (B) and it will seat itself with an audible click

when the headstock reaches a positive lock position.

Lift handle (A) to lock headstock.

Rotate knob (B) clockwise until it engages the threads.

Unscrew the index plunger (B, Fig 28) counter clockwise.

Loosen the headstock lock handle (A) and pull the index

plunger (B) to turn the headstock.

Fig 28-1

For larger workpieces the head stock will have to be turned

90°, the extension added to the tool rest.

Caution:

always operate lathe with the headstock locked in

position.

The headstock can be positioned anywhere along the

machine bed.

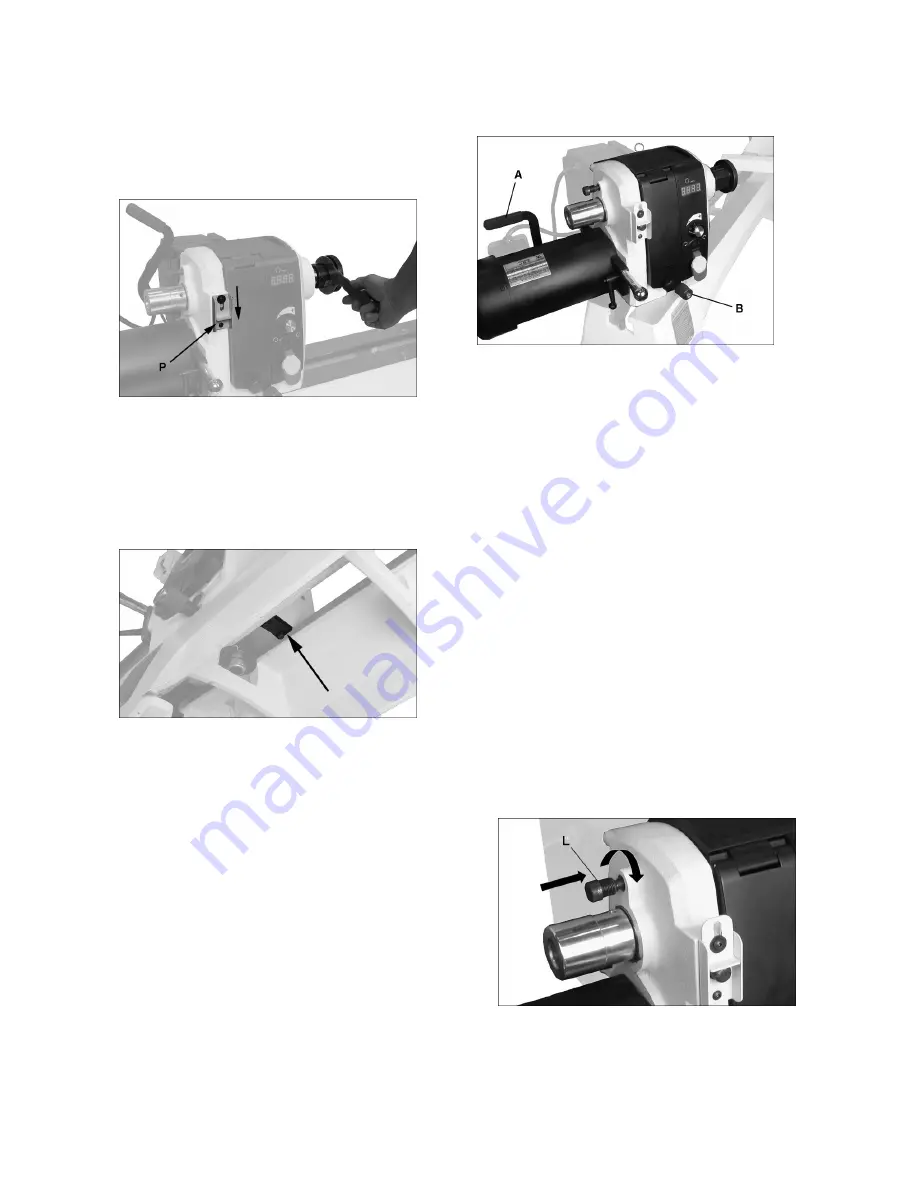

7.4 Headstock spindle index

Indexing is used to create evenly spaced features in a

workpiece, while keeping the lathe spindle locked; for

example, when cutting flutes on a spindle blank with a

hand-held router, while the spindle blank is secured

between lathe centers.

The JWL-1640EVS lathe provides 36 indexing positions at

10-degree increments.

Rotate spindle using handwheel until index pin (L, Figure

29) aligns with desired hole.

Screw index pin into hole until it engages spindle.

Perform desired procedure.

Unscrew index pin until spindle is released. Rotate spindle

to next desired hole, and repeat.

Disengage index pin before starting lathe.

IMPORTANT:

Do not use index pin to lock spindle, which

will cause unnecessary wear to the pin. Use spindle lock

for this purpose.

Fig 29