20

Figure 9-10

9.7.2

To Shape Interior of Bowl

1. Stop lathe and move tailstock away. (You may

want to remove the center from the tailstock to

avoid bumping it with your elbow.)

2. Adjust tool support in front of the bowl just

below centerline, at a right angle to the lathe

ways.

3. Rotate workpiece by hand to check clearance.

4. Face off top of bowl by making a light shearing

cut across the top of workpiece, from rim to

center.

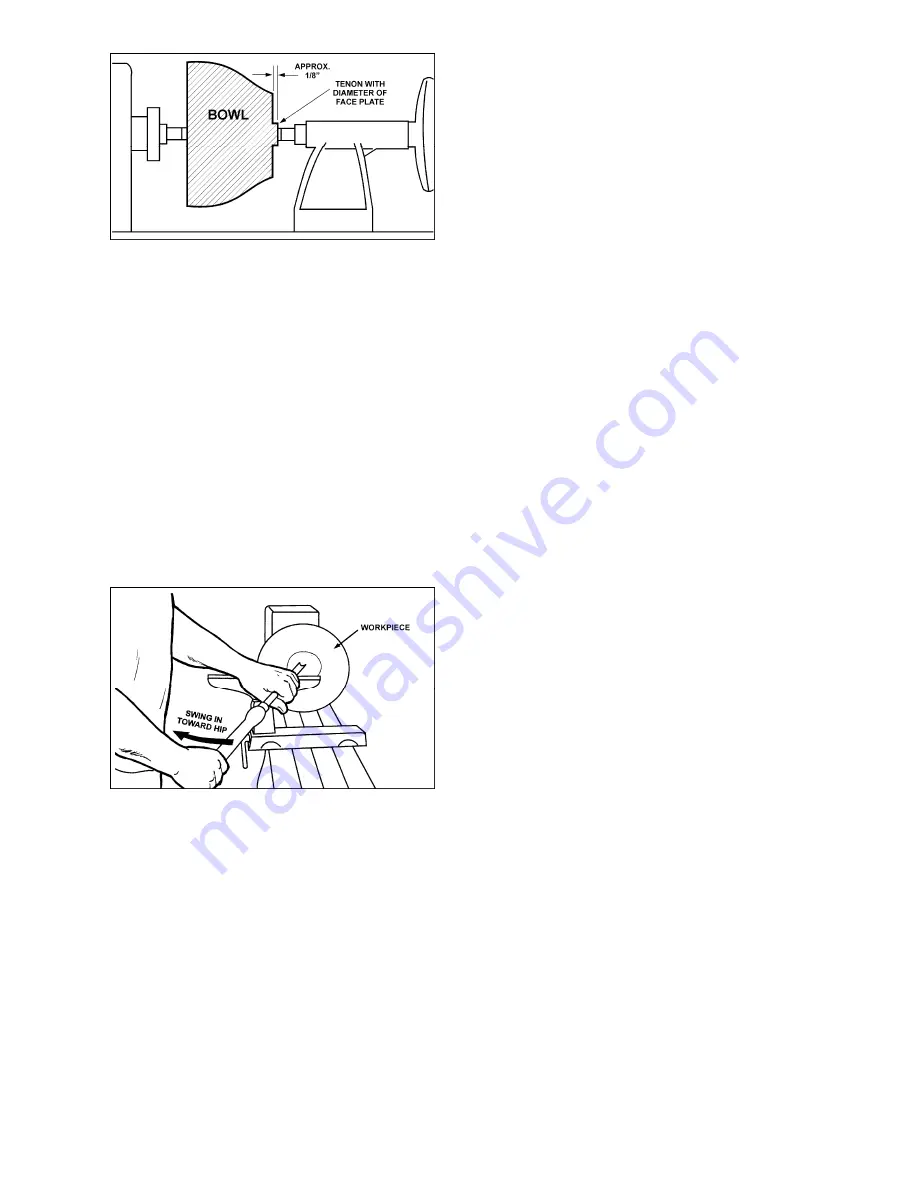

5. Place 1/2" bowl gouge on tool support at

center of the workpiece with the flute facing

top of bowl. The tool handle should be level

and pointed toward the four o'clock position, as

shown in Figure 9-11.

Figure 9-11

6. Use the left hand to control cutting edge of

gouge, while right hand swings tool handle

toward your body (Figure 9-11). The flute

should start out facing top of workpiece, and

rotate upward as it moves deeper into the bowl

to maintain a clean even curve. As the tool

goes deeper into the bowl, progressively work

out toward the rim. It may be necessary to turn

the tool support into the piece as you get

deeper into the bowl.

(NOTE: Try to make one, very light continuous

movement from the rim to the bottom of the

bowl to ensure a clean, sweeping curve

through the piece.

Should there be a few small ridges left, a light

cut with a large domed scraper can even out

the surface.)

7. Develop wall thickness at the rim and maintain

it as you work deeper into the bowl (Once the

piece is thin toward the bottom, you cannot

make it thinner at the rim). When the interior is

finished, move the tool support to exterior to

re-define bottom of bowl. (General rule of

thumb: the base should be approximately 1/3

the overall diameter of the bowl).

8. Work the tight area around faceplate or chuck

with 1/4" bowl gouge.

9. Begin the separation with a parting tool, but do

not cut all the way through yet.

9.7.3

Sanding and Finishing

1. Remove the tool support and adjust lathe

speed to approximately 500 RPM. Higher

speeds can build friction while sanding and

cause heat check in some woods.

2. Begin with fine sandpaper (120 grit) and

progress through each grit, using only light

pressure. Coarser sandpaper tends to leave

deep scratches that are hard to eliminate. Use

power-sanding techniques to avoid concentric

sanding marks around your finished piece.

Avoid rounding over the rim and foot with

sandpaper; try to keep details crisp. Finish

sanding with 220 grit.

3. Remove sanding dust with tack rags or

compressed air and, with lathe turned off,

apply first coat of finish. Let stand for several

minutes, wipe off excess. Allow to dry before

sanding again with 320 or 400 grit sandpaper.

4. Turn lathe back on and continue the

separation cut almost all the way through the

base. Stop at about 3" and use a small fine

tooth saw to separate the bowl from the waste.

5. Apply second finish coat and allow to dry

before buffing.

Summary of Contents for JWL-1640EVS

Page 24: ...24 14 1 1 JWL 1640EVS Headstock Assembly Exploded View ...

Page 28: ...28 14 3 1 JWL 1640EVS Bed and Stand Assemblies Exploded View ...

Page 32: ...32 15 0 Electrical Connections for JWL 1640EVS ...

Page 34: ...34 This page intentionally left blank ...

Page 35: ...35 This page intentionally left blank ...

Page 36: ...36 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...