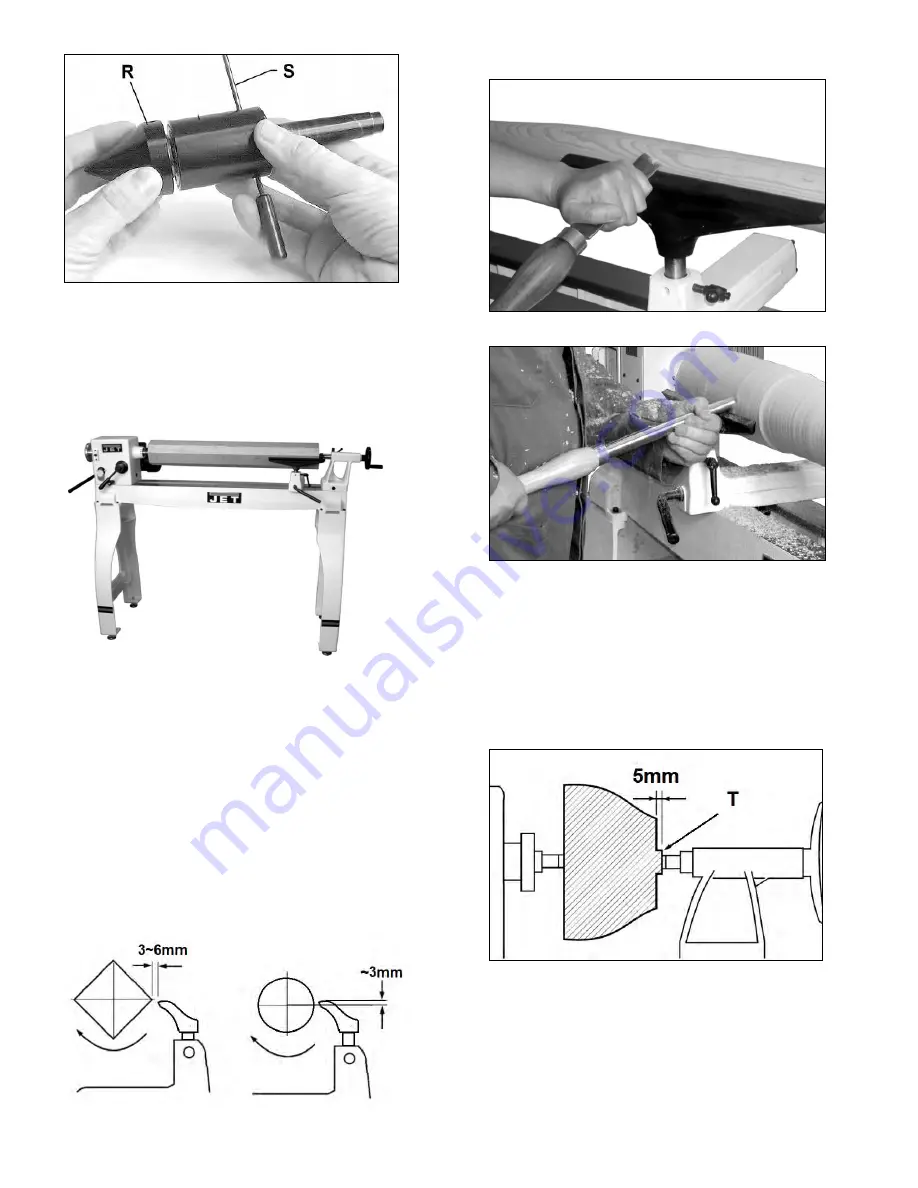

Fig 22

The centring pin can be knocked out to allow deep hole

drilling operations.

Mount the centred workpiece between the spur drive centre

and the tailstock mounted live centre (Fig 23).

Fig 23

Turn the tailstock hand wheel until the live centre well

penetrates the workpiece. Reverse the hand wheel by one

quarter turn and lock the tailstock spindle (M, Fig 21).

Turn the workpiece by hand to see if it rests securely

between centres and can be rotated freely.

Position the tool rest as close to the workpiece as possible.

Tighten locking handles.

For turning between centres the tool rest is set

approximately 3mm higher than centre line (Fig 24, 25 and

26).

Fig 24

Fig 25

Fig 26

6.5 Bowl turning

Turn outside of bowl between centres.

Turn a short tenon the size of the hole in the faceplate

(T, Fig 27).

This will allow centring the workpiece.

Fig 27

Mount the workpiece (A, Fig 28) directly to the face plate

using 4 wood screws (C) from the back. Be careful to use

screws short enough not to interfere with the cutting

process but long enough to hold the workpiece securely to

the face plate.