13

If the planer shuts off frequently, refer to

sect. 10.0

Troubleshooting

.

8.2

Depth of Cut

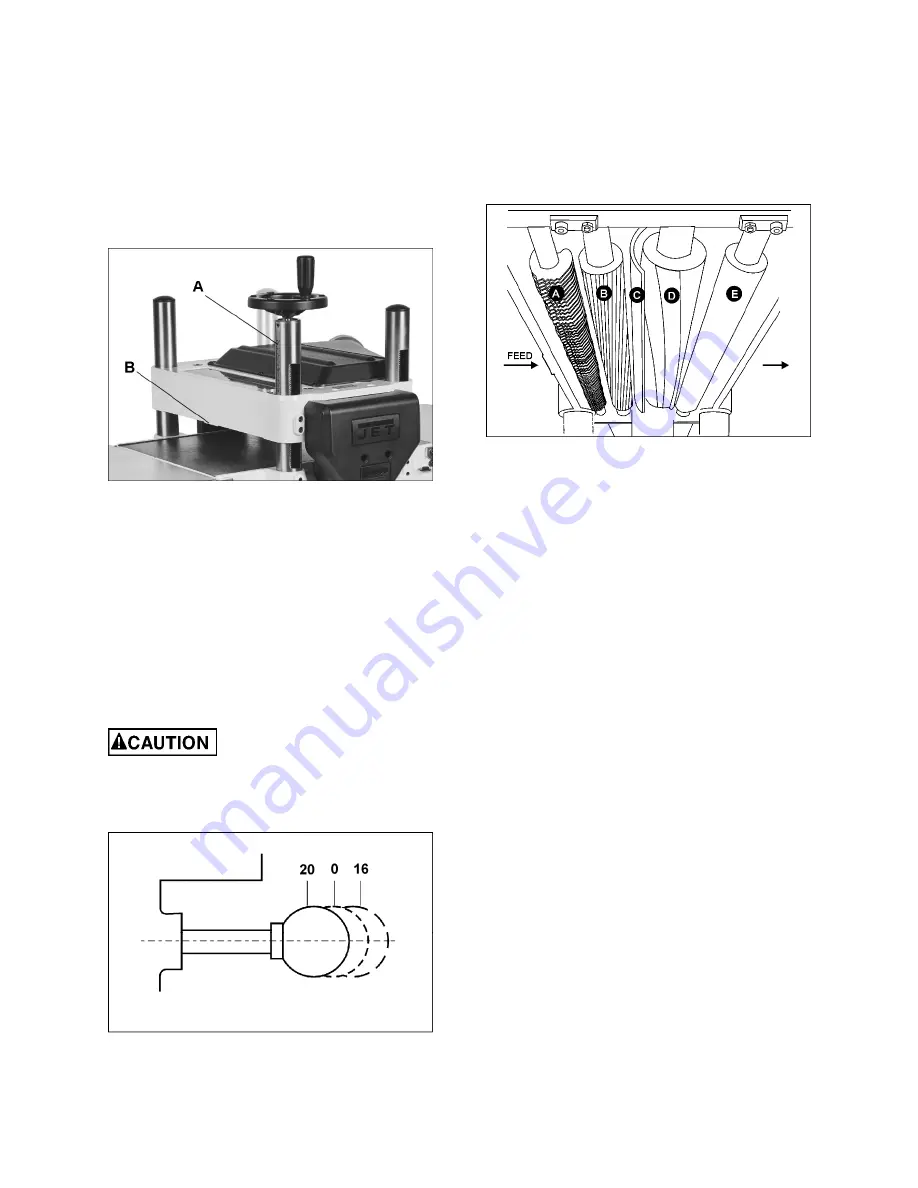

The cutting depth scale is a combination inch/metric

scale (Figure 8-2), with a cutting range from 0 to 6"

(152.4mm). A manual scale is mounted directly to

the front column.

The distance of upward or downward movement is

controlled by the handwheel.

Figure 8-2

Maximum depth of cut is 3/16". A lip on the front of

the head casting (B, Figure 8-2) limits the depth of

cut on full width planing under 1/8".

8.3

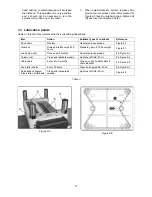

Feed speed

The gear box has two feed speeds. These are set

by pulling out or pushing in the shift lever, located

beneath the gearbox cover.

Always change feed

speed while the machine is running.

A diagram

showing lever positions is molded into the gearbox

cover just above the lever. It is also shown in Figure

8-3.

Planer must be running when

changing feed rate. Do not attempt to change

feed speed while stock is passing through the

machine. Failure to comply may damage

gearbox.

Figure 8-3

8.4

Transmission rollers overview

See Figure 8-4.

A. Anti-kickback fingers

B. Infeed roller

C. Chipbreaker

D. Cutterhead

E. Outfeed roller

Figure 8-4

8.5

Anti-kickback fingers

The anti-kickback fingers (A, Figure 8-4) are an

important safety feature, as they help prevent

kickback of stock. They operate by gravity and

should be inspected frequently to make sure they

are free of gum and pitch, so that they move

independently and operate correctly.

8.6

Feed rollers spring tension

The infeed roller (B, Figure 8-4) and outfeed roller

(E, Figure 8-4) feed the stock while it is being

planed. These rollers are under spring tension and

this tension must be sufficient to feed the stock

uniformly through the planer without slipping, but

should not be so tight that it causes damage to the

workpiece. The tension should be equal at both

ends of each roller. Note: Contact JET Technical

Service before attempting any adjustments to spring

tension.

8.7

Feed rollers height

The infeed roller, chipbreaker and outfeed roller are

adjusted at the factory. The height relationship

between these items and the cutterhead is crucial

for accurate and safe planing. The infeed roller and

outfeed roller should each be set at 0.032"

(0.81mm) below the arc of the cutting knives. The

chipbreaker is set even with the cutting arc. See

Figure 8-6.

If any adjustments are necessary for the infeed or

outfeed roller, they should be done carefully. Use

the steps in

sect. 8.7.1

as an example of procedure.

Summary of Contents for JWP-15B

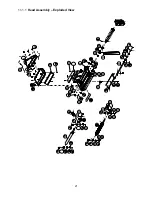

Page 21: ...21 11 1 1 Head Assembly Exploded View ...

Page 23: ...23 11 2 1 Column Assembly Exploded View ...

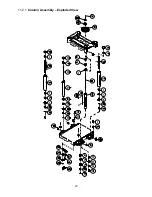

Page 26: ...26 11 4 1 Gear Box Assembly Exploded View ...

Page 28: ...28 11 5 1 Cabinet Assembly Exploded View ...

Page 32: ...32 12 0 Electrical Connections for JWP 15B 15BHH ...

Page 34: ...34 This page intentionally left blank ...

Page 35: ...35 This page intentionally left blank ...

Page 36: ...36 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...