17

head casting; counterclockwise will decrease

the distance. This adjustment is very sensitive

and it should not be necessary to turn the

sprocket more than one or two teeth.

7. When adjustments are correct, replace chain

around corner sprocket, slide idler sprocket (S,

Figure 9-3) back to re-tension chain, tighten bolt

(R) and insert and tighten bolt (P).

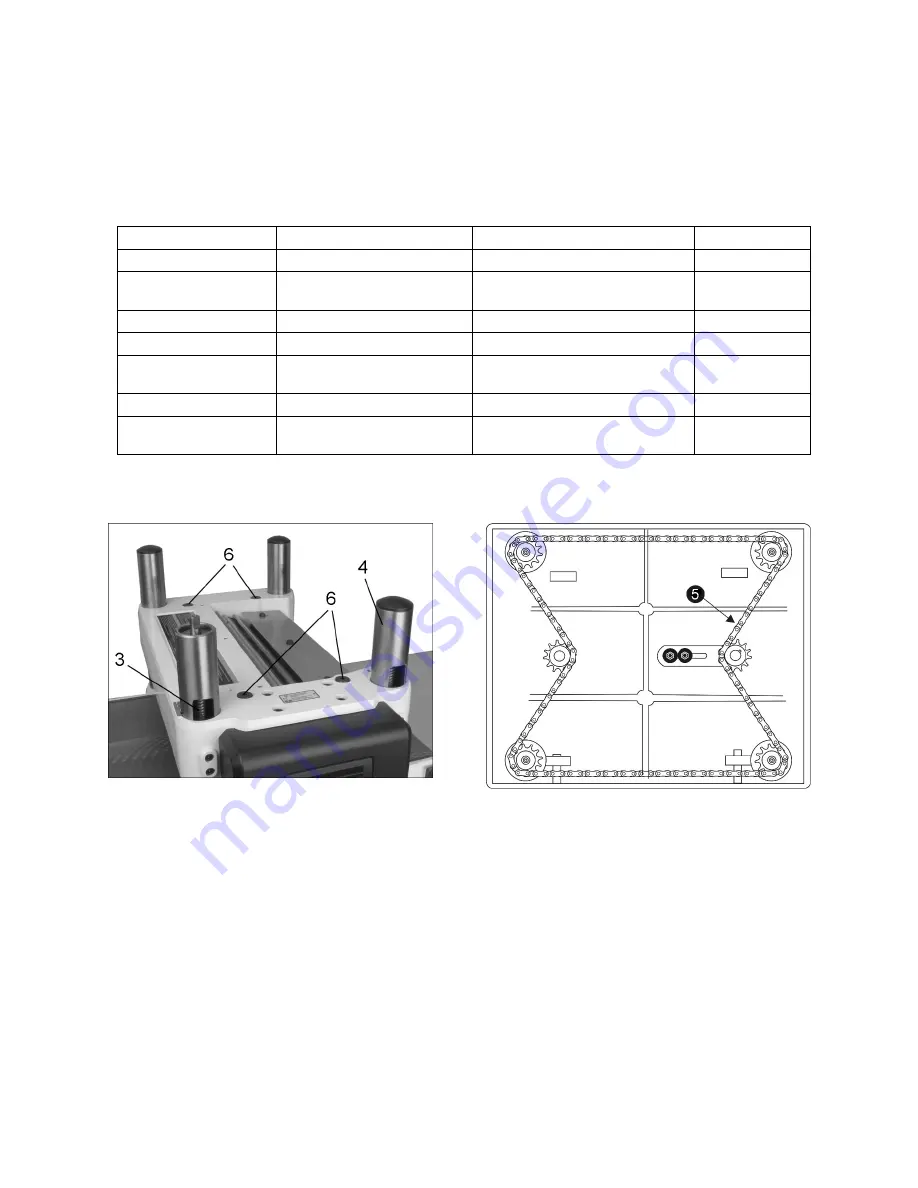

9.4

Lubrication points

Items on this chart are referenced to the surrounding illustrations.

Item

Action

Suitable Types of Lubricant

Reference

Drive chain

Monthly

General purpose grease

Figure 9-1

Gear box

Drain and refill every 2,500

hours

Standard gear oil, 70-90 weight

Figure 9-1

Lead screw (x4)

Once every 3 months

General purpose grease

#3, Figure 9-4

Column (x4)

Clean and lubricate weekly

Light coat of SAE-30 oil

#4, Figure 9-4

Table chain

Every 4 to 6 months

Grease, or good quality bicycle

chain lubricant

#5, Figure 9-5

Feed roller shafts

Every 30 hours

Clean and apply SAE-30 oil.

#6, Figure 9-4

Anti-kickback fingers,

infeed roller, cutterhead

Clean and lubricate as

needed.

Light coat of SAE-30 oil.

Figure 8-4

Table 3

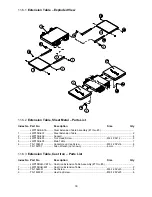

Figure 9-4

Figure 9-5

Summary of Contents for JWP-15B

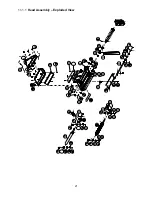

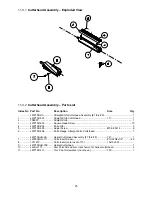

Page 21: ...21 11 1 1 Head Assembly Exploded View ...

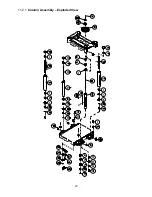

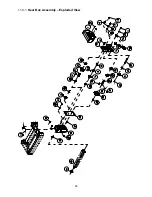

Page 23: ...23 11 2 1 Column Assembly Exploded View ...

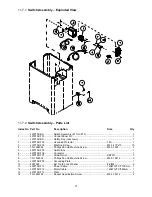

Page 26: ...26 11 4 1 Gear Box Assembly Exploded View ...

Page 28: ...28 11 5 1 Cabinet Assembly Exploded View ...

Page 32: ...32 12 0 Electrical Connections for JWP 15B 15BHH ...

Page 34: ...34 This page intentionally left blank ...

Page 35: ...35 This page intentionally left blank ...

Page 36: ...36 427 New Sanford Road LaVergne Tennessee 37086 Phone 800 274 6848 www jettools com ...