8

Assembly

Tools required for assembly:

Forklift or hoist with slings

Open-end wrenches (provided)

Hex wrenches (provided)

16mm open-end wrench

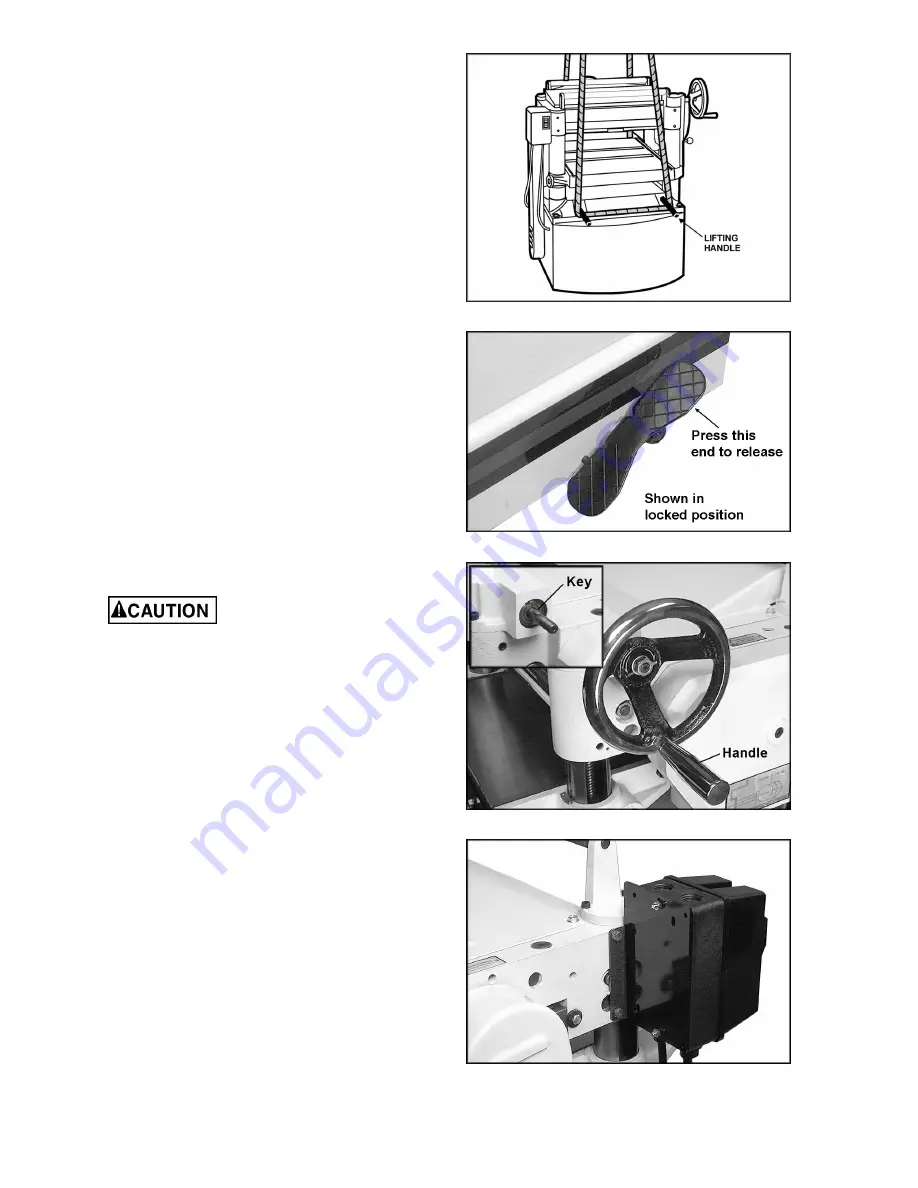

Remove the screws holding the planer to the

pallet and use a forklift or hoist to lift the planer

off the pallet. Forks and straps should always be

placed under the four lifting handles when lifting

this machine (Figure 3). The lifting handles can

be pushed back in when not in use.

The planer should be operated in a well-lit area

with good ventilation. It can be rolled on its

casters to the desired location. Press the foot

pedal (Figure 4) to lock the casters during

operation or adjustments.

Exposed surfaces, such as tables, rollers,

cutterhead, etc., have been given a protective

coating at the factory. This should be removed

with a soft cloth moistened with a good

commercial solvent. Do not use acetone,

gasoline, lacquer thinner, or other solvents with

a low flash point. Do not use an abrasive pad

because it may scratch the polished cast iron

surfaces.

Use care when cleaning

around the cutterhead area; knives are

extremely sharp.

Handwheel

1. Place the key into the slot on the shaft

(Figure 5), and mount the handwheel to the

shaft, making sure it is oriented so that it

slips over the key.

2. Peel off the backing of the directional label,

and attach it to the center of the handwheel.

Place flat washer and hex nut on shaft and

tighten with 16mm wrench.

3.

Mount the handle in the threaded hole in the

handwheel, and tighten with a 12mm wrench

placed over the flat on the nut.

Control Box

Mount the control box as shown in Figure 6, with

the two socket head cap screws which you’ll find

mounted to the head casting. Use a 5mm hex

wrench.

Figure 3

Figure 4

Figure 5

Figure 6

Summary of Contents for JWP-15DX

Page 23: ...23 Head Assembly ...

Page 26: ...26 Base Assembly ...

Page 28: ...28 Table Assembly ...

Page 30: ...30 Gear Box Assembly ...

Page 32: ...32 Stand and Motor Assembly ...

Page 34: ...34 Electrical Connections ...

Page 35: ...35 ...