17

Figure 25

If the gap difference from one side to the other is

equal to or less than 0.004", no further

adjustment is necessary

If the gap difference from one side to the other

side is grater than 0.004", but less than 0.016",

go to the

Adjusting Work Table Parallel to

Cutterhead (Fine Adjustment)

section.

It the gap difference from one side to the other is

grater than 0.016", the cutterhead assembly

raising chain under the planer base needs to be

adjusted – see the

Adjusting Work Table Parallel

to Cutterhead (Major Adjustment)

section.

Adjusting Work Table Parallel to

Cutterhead (Fine Adjustment)

If the gap difference determined in the previous

section is greater than 0.004" and less than

0.016", perform the adjustment procedure as

follows:

1. Determine which side of the table must be

raised to correct the gap.

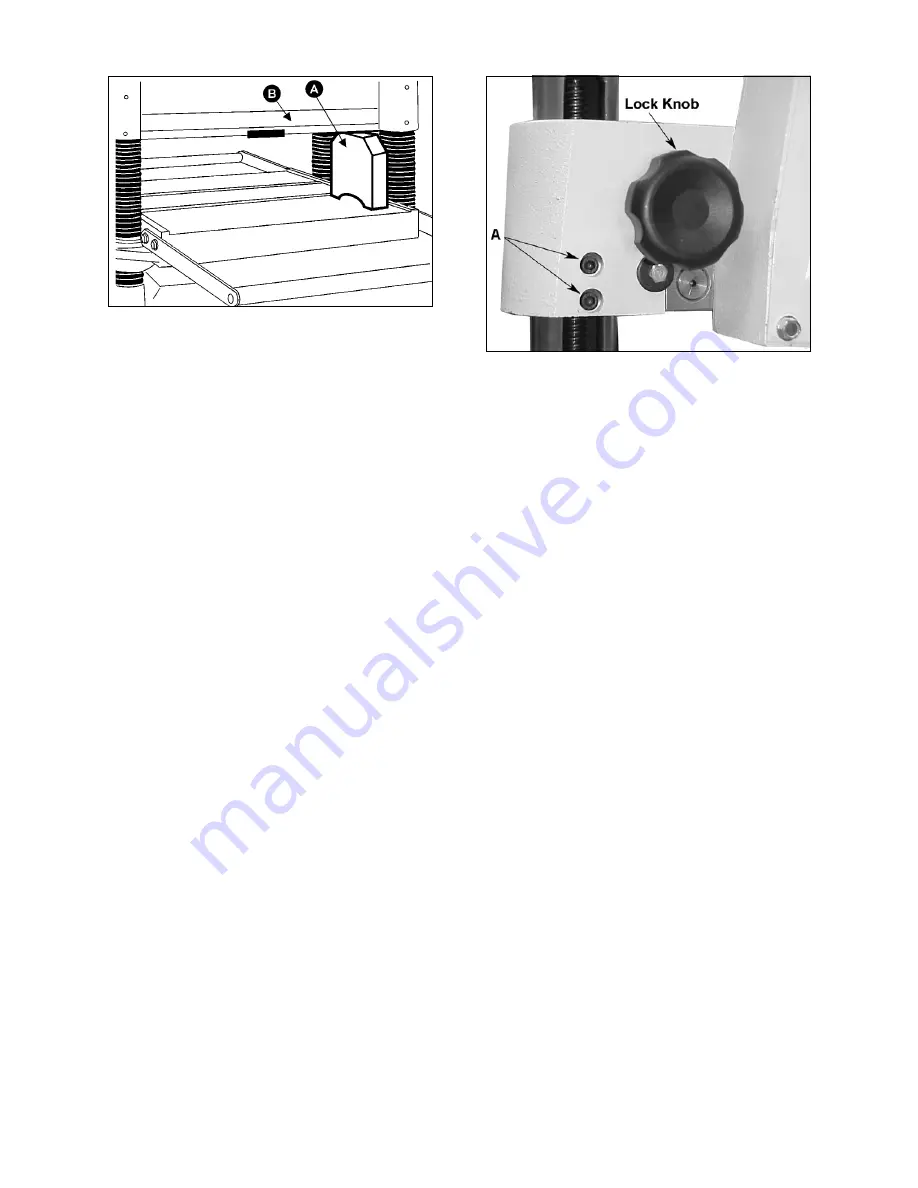

2. Locate the two socket head cap screws in

the table casting for each of the columns (A,

Fig. 26). Loosen both sets of screws for

each column on the side you wish to adjust.

3. Push down or pull up the cutterhead

assembly in the desired direction. Hold the

assembly in position and retighten the cap

screws.

4. Recheck the table to cutterhead parallelism

again as described in the previous section,

then repeat steps 1 – 3 until the deviation is

less than 0.004".

Figure 26

Adjusting Work Table Parallel to

Cutterhead (Major Adjustment)

Refer to Figure 27.

1. Disconnect the machine from power source.

2. On the underside of the base, remove bolt

(A) and loosen bolt (B) which will allow you

to move the idler sprocket assembly (C) far

enough to release tension on the chain.

3. Remove chain from the particular sprocket

on the corner of the base that must be

adjusted.

4. Turn the sprocket by hand to bring that

corner into adjustment with the other three

corners.

Note:

Turning sprocket clockwise will increase

the distance between the working table and

head casting; counter-clockwise will decrease

the distance. This adjustment is very sensitive –

one revolution of the lead screw equals 0.158”

(4mm) of travel. It should not be necessary to

turn the sprocket more than one or two teeth.

5. When adjustments are correct, replace

chain around the corner sprocket, slide

sprocket (C) back to re-tension chain,

tighten bolt (B) and replace and tighten

bolt (A).

Note:

It may be necessary to perform the

Fine

Adjustment

procedure after the major to achieve

the best result.