20

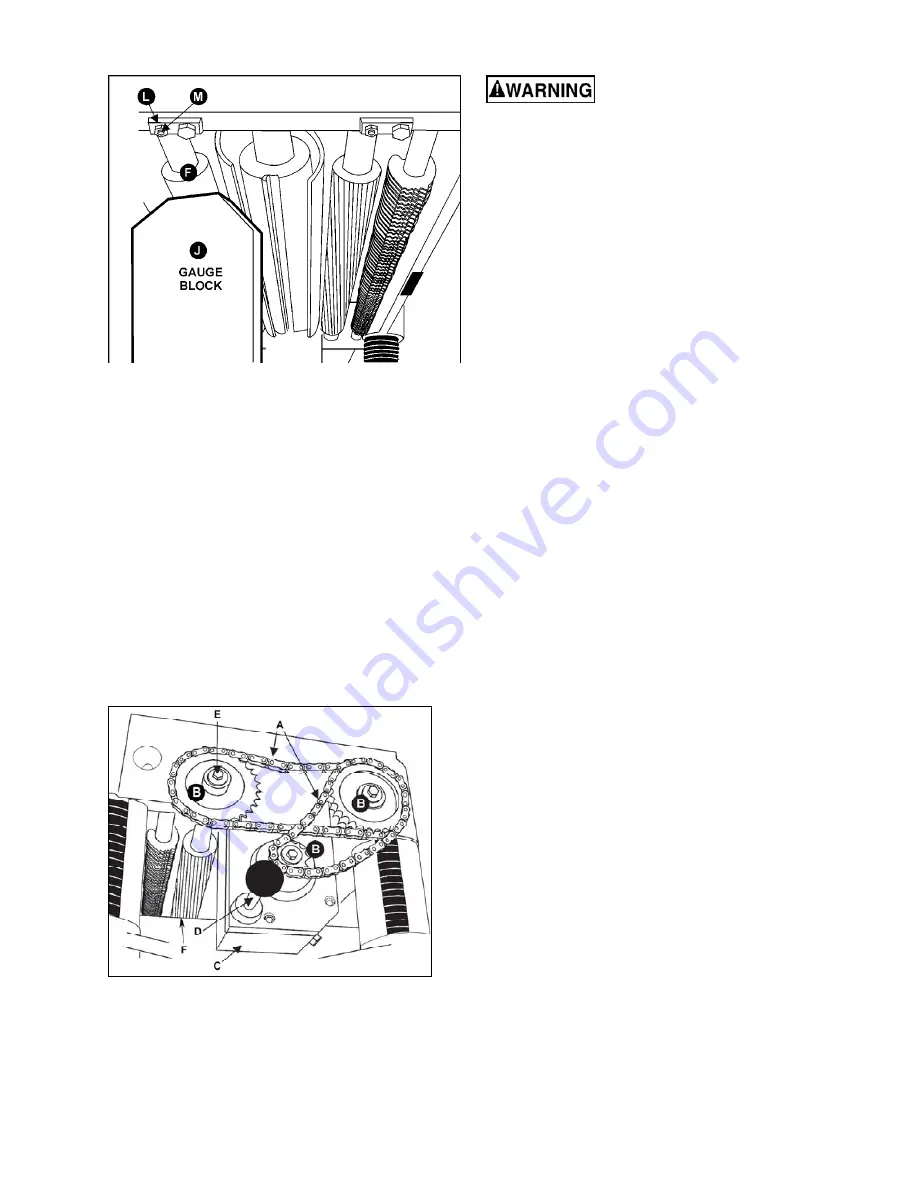

Figure 33

Gearbox

Referring to Figure 34:

The JWP-16OS Planer is equipped with a spiral,

serrated infeed roller (F) and a solid outfeed

roller. When the feed rollers are engaged, they

turn to feed the stock. The feed rollers are driven

by chains (A) and sprockets (B) in the gearbox.

The gearbox is located on the right side of the

planer directly behind the

table lock knob

(A,

Fig. 35). The gearbox transfers power from the

belt-driven cutterhead to the power feed rollers.

A two-speed transmission, controlled by a

push/pull lever (D), moves the stock through the

planer at either 16 or 20 feet-per minute. The

push/pull lever is set

while the machine is

running

.

Figure 34

Operation

The JWP-16OS Planer is a powerful

woodworking machine, designed and

constructed for professional-quality applications.

Because of its powerful motor and razor-

sharp knives, the JWP-16OS Planer is

inherently dangerous and should be

operated with considerable caution and

respect. Failure to do so could result in

damage to the machine or severe injury to

the operator or others in the work area.

Overview

There are a number of safety issues that relate

directly to the operation of the planer. Keep in

mind that these are not all-inclusive. Work

situations, wood types, and other variables that

differ from shop to shop must be considered in

order to operate this planer safely. Always

consider safety and common sense first when

operating this or other machinery.

1. Always inspect lumber for defects (warping,

cupping, twisting, etc.). Do not use lumber of

questionable quality.

2. Check lumber for nails, staples, imbedded

gravel, etc. before planing.

3. Use the full width of the planer. Alternate

between the left, the right and the middle

when feeding lumber into the planer. Your

knives will remain sharp much longer.

4. Remove glues, epoxies and other foreign

matter before planing lumber.

5. Never attempt to plane laminates,

particleboards, plastics or other man-made

materials.

6. Plane wood with the grain. Never plane

across the grain.

7. Do not use boards with loose knots, splits,

cross grain or other defects. They can

damage the machine and cause injury.

8. Keep your work area clear.

9. Wood with excessive water content or wood

exposed to rain, ice, or snow will plane

poorly and cause excess wear to the knives

and motor. Excessive moisture will also

hasten rust and corrosion.

10. Learn as much as possible about planing

procedures. Alternative publications present

more wood specific planing requirements.

Table Locks

Before attempting to adjust table height, loosen

the two

table lock knobs

, one on the right front of

the head casting assembly (A, Fig. 35) and the

other on the left rear.