22

Maintenance

General

Inspect your planer each time before using.

Check for the following conditions and repair or

replace when necessary.

1. Loose mounting bolts.

2. Worn

switch.

3. Worn or damaged cords and plugs.

4. Damaged

V-belts.

5. Any other condition that could hamper the

safe operation of this machine.

Buildup of sawdust and other debris can cause

your machine to plane inaccurately. Periodic

cleaning is not only recommended but also

mandatory for accurate planing.

Close-fitting parts, such as the cutterhead slot

and gibs, should be cleaned with a cloth or

brush and non-flammable solvent, and free from

clinging foreign matter.

Remove resin and other accumulations from

feed rollers and table with a soft rag and non-

flammable solvent.

Periodically check all the chains for proper

tension and adjust accordingly if required.

Tip:

If a foreign object nicks the knives, instead

of throwing them away or trying to grind out the

deep nick, simply stagger the knives in the head,

moving one knife no more than 1/8" to the right

and another knife no more than 1/8" to the left.

The nick should no longer be noticeable.

The table should be kept clean and free of rust.

Some users prefer a paste wax on exposed

steel and cast iron surfaces. The wax provides a

layer of protection as well as reducing friction

between lumber and the table making cuts faster

and smoother. Avoid any wax that contains

silicone or other synthetic ingredients. These

materials can find their way into lumber and can

make staining and finishing difficult.

Another option is talcum powder applied with a

blackboard eraser rubbed in vigorously once a

week; this will fill casting pores and form a

moisture barrier. This method provides a

tabletop that is slick and allows rust rings to be

easily wiped from the surface. Another important

fact is that talcum powder will not stain wood or

mar finishes as wax pickup does.

Sharpening Knives

It is recommended that knives be replaced they

become dull or damaged.

If knives

are

to be reused, it is recommended

that they be sharpened by a professional knife

sharpener. Improperly sharpened knives can

cause a number of defects to lumber and put

unnecessary load on the motor and drive

systems.

If you must sharpen the knives yourself, please

take note of the following information:

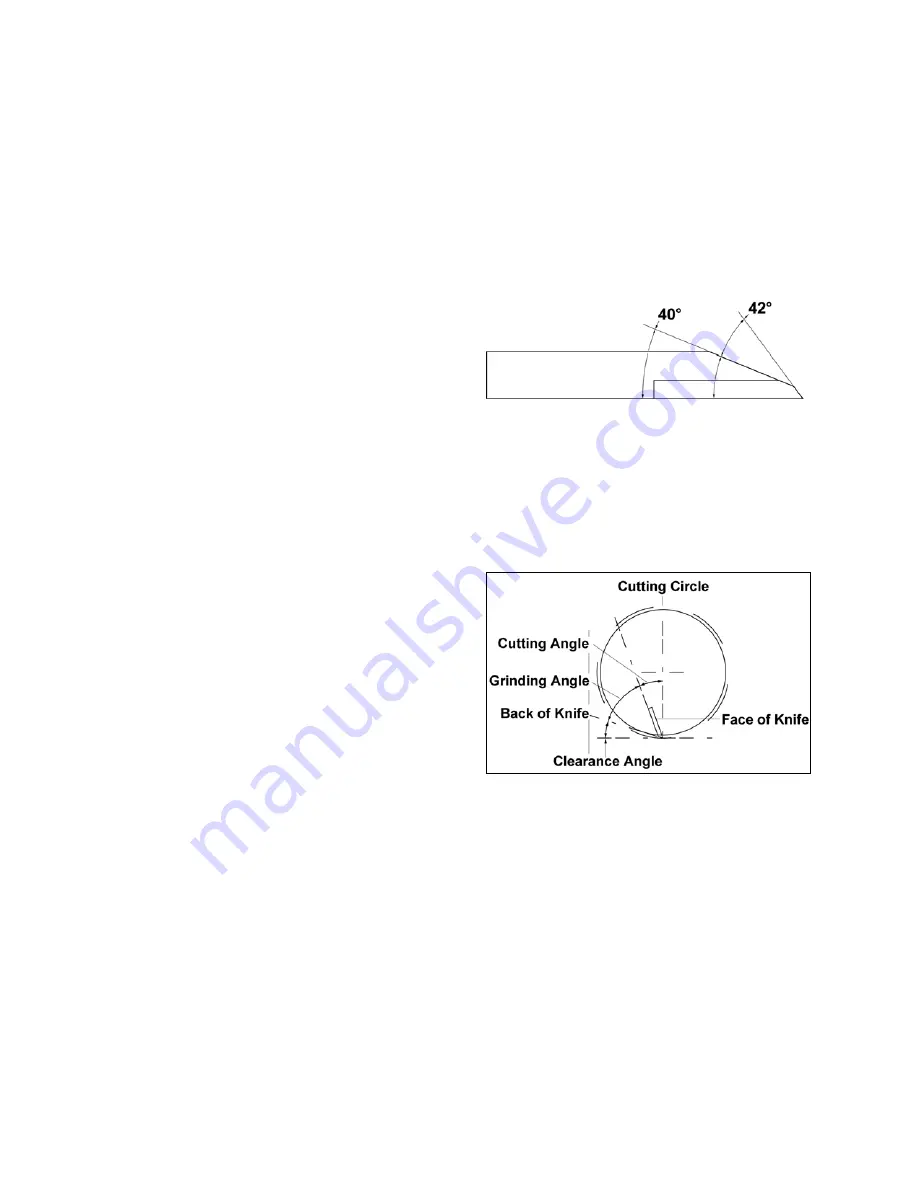

Primary Grinding Angle – 40 degrees

Secondary Grinding Angle – 42 degrees

The grinding angle has been determined by the

factory to be the best compromise for planing a

wide variety of wood types. In most cases, that

angle will produce excellent results. If you

choose to change the angle of your bevel, be

sure to consult with a trained sharpener or with a

reference book before you commit to changing

the angle of bevel.

Figure 38