Router bits may only be operated in the highest spindle speed

(8000 rpm).

Disengage the spindle rotation lock.

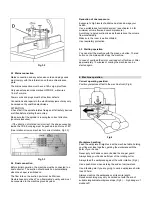

Set the fence boards approx. 5mm close to the cutter rotation

(Fig 19.1).

Check if the spindle rotates freely and if all safety devices are

fitted and tightened.

Connect the machine to the power source.

Start the shaper cautiously.

7.4 Cutting tool installation

The cutting tool may only be changed when the spindle

rotation lock is engaged and the mains plug is pulled.

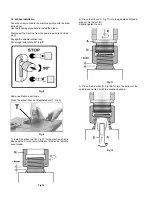

Risk of personal injury by cuts from the cutter knives. Wear

suitable gloves when changing cutters.

Clean all surfaces of cutters and spindle arbours with a

suitable solvent (do not use cleaning agents that could

corrode the light metal components).

To reduce the danger of kick-back and injury.

Only cutting tools marked “MAN” and conforming EN 847-1

respectively EN 847-2 may be used.

Unsuitable, incorrectly mounted, dull, cracked of bent cutter

knives can break or increase the risk of kickback considerably.

The installation of sanding or polishing tools is not

permissible.

The installation of saw blades is not permitted, high risk of

kickback and serious injury !

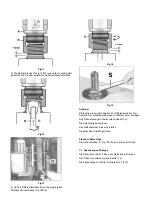

The cutter must be positioned on the arbour (F, Fig 18.1) as

low as possible (Fig 17).

Fig 17

Watch the sense of rotation (counter clockwise) when

mounting the cutter.

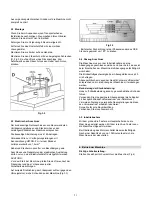

Fill the space between cutter (B, Fig 18.1) and clamping

washer (C) with spacing collars (E).

Fig 18.1

Tighten the tool with the socket hex screw (D, Fig 18.1)

securely. (Don’t use a wrench extension or a hammer to

tighten the screw)

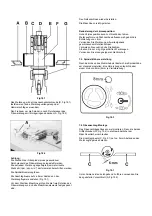

Cover the clearance zone around the cutter with table insert

rings (A, Fig 18.2).

Fig 18.2

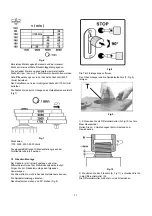

ATTENTION:

Adapt the spindle speed to the cutting tool diameter.

Never exceed the shown numbers of revolution (rpm, /min,

min

-1

) on the tool.

Disengage the spindle rotation lock.

Set the fence boards approx. 5mm close to the cutter rotation

(Fig 19.1).

Check if the spindle rotates freely and if all safety devices are

fitted and tightened.

Connect the machine to the power source.

Summary of Contents for JWS-34KX

Page 44: ...A 1 A 2 A 3 A 4 A 5 ...