*Too heavy a cut-

make several passes.

*knives cutting against grain-

turn workpiece around.

*Workpiece inhomogeneous.

*Moisture content too high.

Snipe

*Inadequate fence board adjustment- use spacer board where

possible.

*Clearance to table hole too big-

use table insert rings.

*insufficient workpiece guiding-

improve hold downs setting.

Spindle quill difficult to adjust

*Lack of lubrication-

lubricate spindle quill

*Quill is clamped.

Poor machining power

*belt is slipping-

tighten belt.

*Resin build up on tables-

clean and wax table surfaces.

10. Environmental protection

Protect the environment.

Your appliance contains valuable materials which can be

recovered or recycled. Please leave it at a specialized

institution.

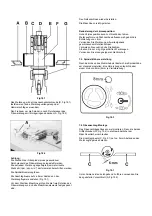

This symbol indicates separate collection for electrical and

electronic equipment required under the WEEE Directive

(Directive 2012/19/EC) and is effective only within the

European Union.

11. Available accessories

Stock number 10000251

30mm spindle arbour incl. spacing collars.

Stock number 10000252

Sanding spindle with drums and sanding sleeves dia. 25, 38,

50, 75, 100mm

-refer to the Jet-Pricelist for various grit sanding sleeves (see

JVOS-10 and JOSS-10).

Stock number 10000253

Tenoning carriage

Stock number 709207

Foldable roller stand

12. Safe operation

See appendix A (on the last pages of this operating manual).

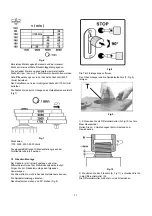

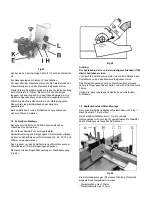

A.1 : Machining of boards

A.2 : Longitudinal machining

A.3 : Face machining

A.4 : Recess machining.

A.5 : Contour machining

Summary of Contents for JWS-34KX

Page 44: ...A 1 A 2 A 3 A 4 A 5 ...