9

HOOKS

WARNING

1. Any hook that requires replacement because of excessive bends, twists, or throat opening indicates abuse or

overloading of the hoist. Therefore, other load-supporting components of the lever hoist should be inspected for

possible damage when such conditions are found.

2. Never repair hooks by welding or reshaping. Heat applied to the hook will alter the original heat treatment of the hook

material and reduce the strength of the hook.

3. Never weld handles or other attachments to the hook. Heat applied to the hook will alter the original heat treatment of

the hook material and reduce the strength of the hook.

HOOKS INSPECTION

Refers to ASME B30.10, Safety Standard for Hooks. Inspect hooks and measure hook throat opening at least once a

month. Between regular inspections check visually daily for deformation, distortion, twisting, damage, and missing or

damaged hook latches. Inspect as follows:

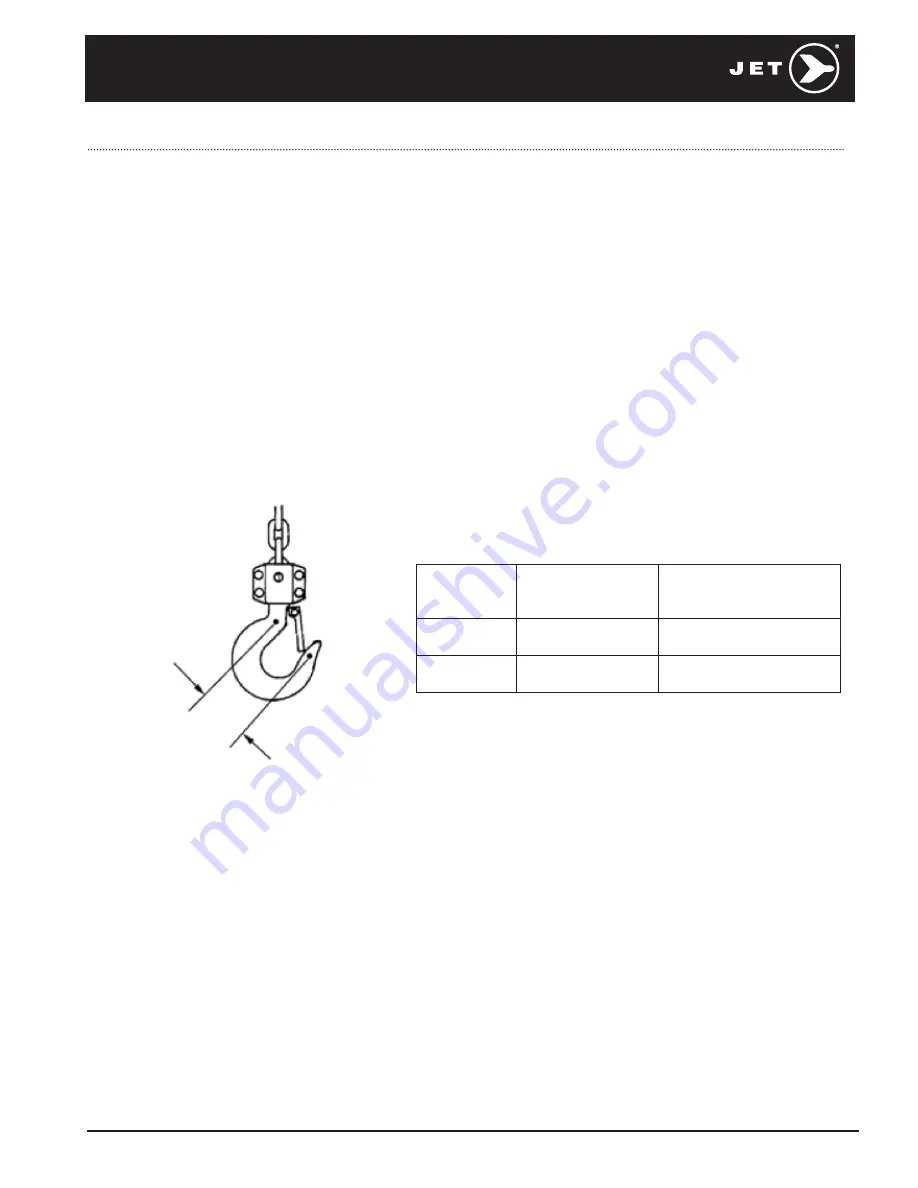

1. Measure hook opening at raised dots (Figure 7) to check for stretch. Raised dots provide a constant reference point

and eliminate measurement errors. Replace hook when measurement between dots reaches “Dimension A Replace

Hook” figures below.

Figure 7

Hoist

Capacity

"A" Dimension

Normal (mm)

"A" Dimension

Replace Hook if ≥ (mm)

0.25 ton

35.5

37.3

0.50 ton

41

43.1

2. A bend or twist of the hook exceeding 10° from the plane of the unbent hook requires replacement of the hook.

3. A hook latch that is missing shall be replaced.

4. A hook latch that is inoperative shall be repaired or replaced.

5. A hook with a hook latch that does not close the throat opening of the hook shall be removed from service until the

latch is replaced or repaired.

6. Hooks having damage from chemicals, corrosion, or deformation shall be repaired or replaced.

Due to variations in the manufacturing process, the dimensions of a new hook are variable. For accurate record

keeping, we recommend users record measurement of Dimension A of the hook before use. Record this information

in the spaces above and calculate the replacement value by multiplying by 1.05 for Dimension A.

A