5

5. Transport and start up

5.1 Transport and installation

For transport use a forklift or hand

trolley. Make sure the machine does

not tip or fall off during transport.

The machine is designed to operate in

closed rooms and must be placed

stable on firm and levelled ground.

The machine can be bolted down if

required.

For packing reasons the machine is

not completely assembled.

5.2 Assembly

If you notice transport damage while

unpacking, notify your supplier

immediately. Do not operate the

machine!

Dispose of the packing in an

environmentally friendly manner.

Clean all rust protected surfaces with

a mild solvent.

Cabinet stand assembly

Attach the four rubber pads (A, Fig. 1)

to the bottoms of the side panels with

4 screws, 4 flat washers and 4 hex

nuts.

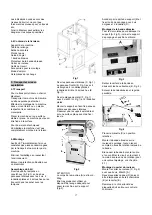

Fig 1

Attach the side panels (C) to the front

panel (D) with 4 hex cap bolts, 8 flat

washers, 4 lock washer, and 4 hex

nuts (E).

Mount the shelf (F) to the inside of the

stand with 2 pan head screws M5 (G)

and 2 lock washers.

Finish stand assembly by attaching

rear panel to side panels. Make sure

stand is sitting evenly on a level

surface before tightening hardware.

Fig 2

WARNING:

Main unit (A) is 95kg heavy!

Use great care and adequate

resources when lifting the unit up onto

the stand (B).

Through the door in the cabinet (E)

attach main unit to stand with two hex

cap bolts and two flat washers (D).

Sanding belt installation

Unlock the platen assembly

(A, Fig. 3).

Fig 3

Tilt sanding unit to the vertical

position, and lock handle.

Remove the belt guards by

unscrewing two lock knobs (B Fig. 4).

Take out sanding belt and fence

packed behind the belt guard.

Fig 4

Move the handle (C) to the no-belt-

tension position.

Place belt on both rollers so that the

edge of the belt is even with the edge

of the rollers.

Observe direction arrow on inside of

sanding belt. Make sure that direction

arrow on belt matches direction

indicator on the belt cover.

Tension the belt if in place.

Rotate the belt by hand in the

direction indicated by the arrow on the

belt guard (If belt tracking needs

adjustment see “Belt Tracking

Adjustment” chapter 8.1)

Drum guard assembly

Attach the drum guard (C, Fig 5) with

four M4x20 screws (A).

Two rectangular spacers (D) need to

be placed between hinges (B) and belt

cover (E).

Note: Orient the rectangular spacers

so the slightly rounded side sits

against the hinge.

Fig 5

Attach the connection plate (F) with 2

washers (G) and 2 lock knobs (H).

The slotted side of the connection

plate attaches to the drum guard (C).

When opening or closing the drum

guard, slightly loosen both lock knobs.