4

•

ALWAYS DISCONNECT THE MACHINE FROM THE POWER SOURCE BEFORE SERVICING.

•

REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure the switch is in the off position

before plugging in.

•

USE RECOMMENDED ACCESSORIES. The use of accessories and attachments not

recommended by POWERMATIC may cause hazards or risk of injury to persons.

•

NEVER STAND ON A MACHINE. Serious injury could occur if the machine is tipped.

•

CHECK DAMAGED PARTS. Before further use of the machine, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform its

intended function - check for alignment of moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its operation. A guard or other part that is

damaged should be properly repaired or replaced.

•

NEVER LEAVE THE MACHINE RUNNING UNATTENDED. TURN POWER OFF. Don’t leave the

machine until it comes to a complete stop.

•

SOME DUST CREATED by power sanding, sawing, grinding, drilling and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

•

Lead from lead based paint

•

crystalline silica from bricks and cement and other masonry products, and

•

arsenic and chromium from chemically-treated lumber.

•

Your risk from those exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals: work in a well ventilated area, and work with approved safety

equipment, such as those dust masks that are specifically designed to filter out microscopic particles

•

DO NOT operate tool while under the influence of drugs, alcohol or any medication.

•

AVOID kickback by sanding in accordance with directional arrows. Sand on downward side of disc.

Sanding on the upward side could cause the workpiece to fly up causing injury.

•

SAND with the grain of the wood.

•

DO NOT sand pieces of material that are too small to be safely supported.

•

WHEN sanding a large workpiece, provide additional support at table height.

•

ADDITIONAL INFORMATION regarding the safe and proper operation of this product is available

from the National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201, in the Accident

Prevention Manual for Industrial Operations and also in the safety Data Sheets provided by the NSC.

Please also refer to the American National Standards Institute ANSI 01.1 Safety Requirements for

Woodworking Machinery and the U.S. Department of Labor OSHA 1910.213 Regulations.

•

SAVE THESE INSTRUCTIONS refer to them often and use them to instruct others.

Summary of Contents for PDS-12CS

Page 13: ...13 Base Assembly Breakdown...

Page 15: ...15 Sander Assembly Breakdown...

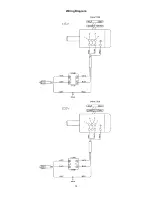

Page 18: ...18 Wiring Diagram...