4

Do not operate the machine under

the influence of drugs, alcohol or any

medication. Be aware that

medication can change your

behaviour.

Keep children and visitors a safe

distance from the work area.

Keep guards in place and in working

order.

Specifications regarding the

maximum or minimum size of the

work piece must be observed.

Support long work pieces with

helping roller stands.

Do not stand on the machine.

4. Machine specifications

4.1 Technical data

SS-5N

Shear capacity (St 37):

Max sheet capacity

4 mm

Max. flat stock

70 x 5 mm

Max. round stock

Ø10 mm

Blade length

120 mm

Overall (LxWxH) 390x175x430 mm

Net Weight

10 kg

SS-6N

Shear capacity (St 37):

Max sheet capacity

5 mm

Max. flat stock

70 x 6 mm

Max. round stock

Ø11 mm Max

Blade length

160 mm

Overall (LxWxH) 400x175x430 mm

Net Weight

13 kg

SS-8N

Shear capacity (St 37):

Max sheet capacity

5 mm

Max. flat stock

70 x 7 mm

Max. round stock

Ø13 mm Max

Blade length

200 mm

Overall (LxWxH) 430x175x430 mm

Net Weight

25 kg

SS-12N

Shear capacity (St 37):

Max sheet capacity

5 mm

Max. flat stock

70 x 6 mm

Max. round stock

Ø13 mm Max

Blade length

300 mm

Overall (LxWxH) 560x175x430 mm

Net Weight

29 kg

*Material strength and ductility may

vary a lot. The given values are for

approximate reference only.

5. Transport and installation

5.1 Transport

If you notice transport damage while

unpacking, notify your supplier

immediately. Do not operate the

machine!

Dispose of the packing in an

environmentally friendly manner.

Clean all rust protected surfaces with

petroleum, diesel oil or a mild

solvent.

Coat all machined surfaces with a

light coat of oil to inhibit rust.

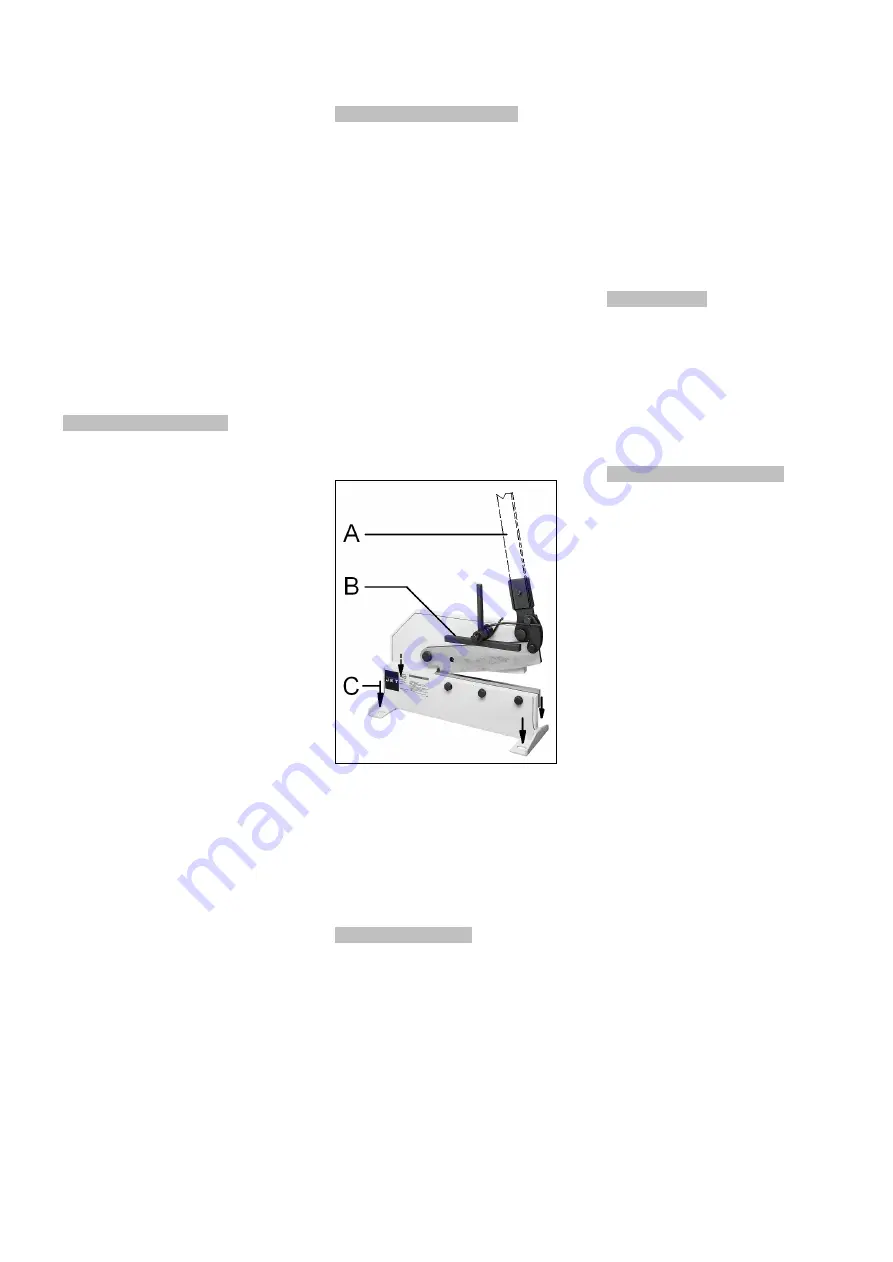

5.2 Installation

The machine is designed to operate

in closed rooms and must sufficiently

be bolted to a cabinet stand or a

solid work bench (C, Fig 1).

Fig 1

To avoid tipping, the machine

must be bolted down!

5.3 Assembly

Mount the operating handle (A).

Mount the hold down (B).

6. Machine operation

Specifications regarding the

maximum or minimum size and

thickness of the work piece must be

observed.

Failure to comply m ay cause severe

machine damage.

The hold down (B) must be lowered

to the work piece to support leverage

forces during the cut.

Support long work pieces with

helping roller stands.

Sheet metal stock has sharp edges.

WEAR GLOVES

when handling

sharp edged work pieces.

WEAR SAFETY GLASSES

.

KEEP HANDS AND FINGERS

clear

of the shearing area.

7. Maintenance

Lubrication:

The machine must be lubricated

every day of service with a few drops

of oil.

Lubricate all slide and pivot points of

the machine.

Coat all machined surfaces with a

light coat of oil to inhibit rust.

8. Environmental protection

Protect the environment.

Your appliance contains valuable

materials which can be recovered or

recycled. Please leave it at a

specialized institution