10

6.2.2

Variable speed model (SWG-272VS)

1. Remove existing plug from power cable and

attach a UL/CSA listed plug designed for 230V

power; or “hardwire” the machine directly to a

panel. If hardwiring make sure a disconnect is

provided for the operator.

No internal rewiring is needed for the inverter to

accept the new input voltage.

6.3

Extension cords

The use of extension cords is discouraged; try to

position your machine within reach of the power

supply. If an extension cord becomes necessary,

make sure the cord rating is suitable for the

amperage listed on the machine’s motor plate. An

undersized cord will cause a drop in line voltage

resulting in loss of power and overheating.

Use the chart in Table 2 as a general guide in

choosing the correct size cord. If in doubt, use the

next heavier gauge. The smaller the gauge number,

the heavier the cord.

Recommended Gauges (AWG) of Extension Cords

Amp Rating

Volts Total length of cord in feet

More

Than

Not

More

Than

120

240

25

50

50

100

100

200

150

300

AWG

0 6 18

16 16

14

6 10 18

16 14

12

10 12 16

16 14 12

12 16 14

12

Not

Recommended

Table 2

7.0

Adjustments

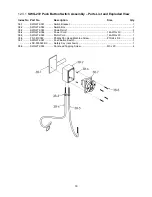

7.1

Platen or Wheel installation

Move switch to OFF to avoid

personal injury.

To install either the platen or the 8-inch serrated

wheel:

1. Pull out on tension lever (shown in Figure 7-3)

and lower it, to release tension on the belt.

2. Loosen knob and raise upper guard (see Figure

7-2). Open side panel by turning its knob and

lowering panel on its hinges.

3. Loosen clamp handle on head casting. See

Figure 7-1.

4. Install pivot shaft of platen (or shaft of wheel) all

the way into head casting, as shown in Figure

7-1.

5. Position platen as desired:

For grinding flat or angular workpieces,

position platen with platen surface facing

outward.

For grinding of cylindrical workpieces,

position platen with “yoke” side facing

outward.

6. Set platen at desired angle and tighten clamp

handle.

7. Install and track the abrasive belt (see sect. 7.3

and 7.4).

8. Raise tension lever to set belt tension.

Do not

overtighten.

9. Bring upper guard down into position and adjust

so that it will not contact abrasive belt. Tighten

upper guard knob.

10. Adjust work rest to 1/16 inch from belt.

7.2

Platen wheel adjustment

The platen wheels have eccentric shafts, which

allow adjustment of the wheels tangent to the

surface of the platen.

Turn one or both screws (A, Figure 7-1) to adjust.

Figure 7-1: installing platen assembly

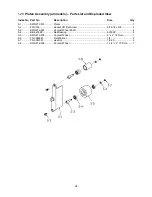

7.3

Installing/replacing grinding belt

Do not operate machine with

side panel open.

1. Lower belt tension lever (see Figure ---) to

release tension on belt.

2. Loosen knob and raise upper guard (see Figure

7-2). Open side panel by turning its knob and

lowering panel on its hinges.

3. If required, loosen work rest to provide

clearance for belt removal.

4. Remove belt from drive wheel, idler wheel, and

contact wheel. Install replacement belt centered

over drive wheel, idler wheel, and contact

wheel. Make sure direction arrows on belt

match machine operation.