20

Gage

Use the standard gage (blade thickness) except

when the increased thickness of the workpiece

decreases accuracy and width cannot be

increased to compensate.

Examples of heavy gage applications:

1. When radius cutting in thick materials.

2. When the maximum width usable on the

machine still provides insufficient beam

strength for the blade. (Beam strength is the

blade’s resistance to compression caused

by strong feeding or the type of material

being cut).

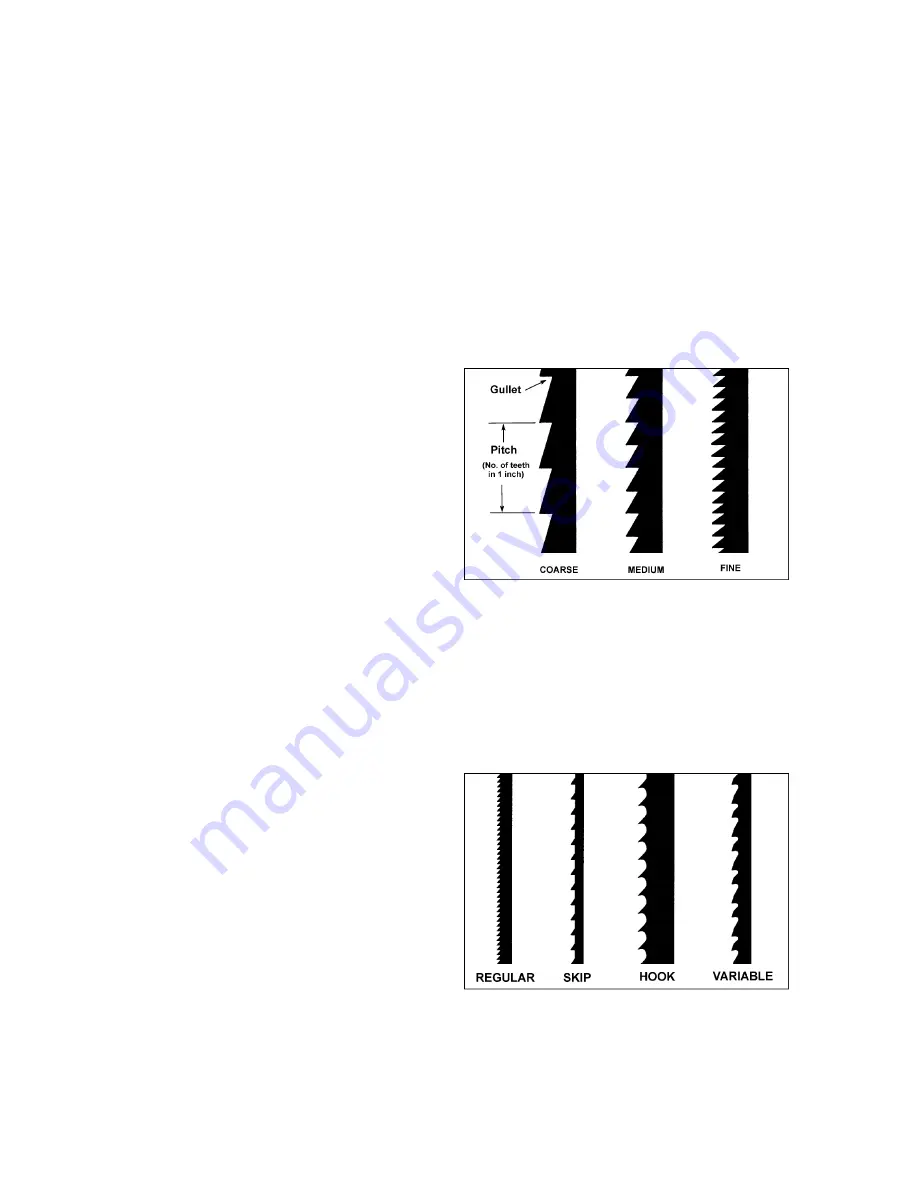

Pitch

Pitch is measured in “teeth per inch” (T.P.I.) and

can be constant or variable. Figure 23 shows

blades with different pitches. A fine pitch (more

teeth per inch) will cut slower but smoother. A

coarse pitch (fewer teeth per inch) will cut

rougher but faster.

As a rule of thumb, the thicker the workpiece,

the coarser will be the blade pitch. If you have to

cut a hard or very brittle material, you will

probably want to use a blade with a finer pitch in

order to get clean cuts.

Using a blade with too few teeth may cause

vibration and a rough cut, while too many teeth

may cause the gullets to fill with shavings and

overheat the blade.

As a general rule, use a blade that will have no

fewer than 6 and no more than 12 teeth in the

workpiece at any given time.

The chart on page 23 will aid in determining

pitch for a particular job.

Shape

Figure 24 shows common types of tooth shape.

Tooth shape has an effect on cutting rate.

The Regular blade, sometimes called a “raker”

blade, has evenly spaced teeth that are the

same size as the gullets, and a 0-degree rake

angle. This is a good general-purpose blade,

and often works well with ferrous metals.

The Skip type has fewer teeth and larger gullets,

providing the added chip clearance needed for

cutting softer, nonferrous materials, as well as

non-metallic applications such as wood, plastic,

cork, and composition materials.

The Hook blade has larger teeth and gullets and

a positive rake angle which permits better feed

and chip removal. It is useful for both cast iron

as well as hard, nonferrous alloys.

Figure 23

Figure 24

Summary of Contents for VBS-3612

Page 23: ...23 Speed and Pitch Chart ...

Page 24: ...24 Typical Band Saw Operations ...

Page 35: ...35 VBS 3612 Band Saw ...

Page 36: ...36 VBS 3612 Band Saw ...

Page 39: ...39 Welder Shear and Work Lamp Assemblies ...

Page 40: ...40 Electrical Connections 3Ph 230 460V ...

Page 42: ...42 Electrical Box see page 41 for identification of parts ...

Page 43: ...43 ...