16

Service and Maintenance

Adjustments

The efficient operation of the band saw is dependent upon the condition of the saw blade.

If the performance of the saw begins to deteriorate, the first item that you should check is

the blade.

If a new blade does not restore the machine’s cutting accuracy and quality, refer to the

troubleshooting guide (or the blade manufacturer’s guide) for conditions to consider and

adjustments that can be made to increase the life of the blade.

To change the blade, refer to the blade changing procedures in the Blade Selection

section of this manual.

Blade Tracking Adjustments

Blade tracking has been tested at the

factory. Adjustment is rarely required

when the blade is used properly and if

the blade is correctly welded. (Refer to

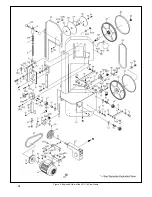

Figure 7 for location of blade tracking

adjustment setscrew).

1. Place the saw frame in its

rearmost position by pushing

down on the saw frame release

lever (Figure 3 Item 2) and lock

it in place by turning the saw

frame release knob (Figure 3

Item 1.2) clockwise.

2. Make sure the blade is properly

tensioned.

NOTE: Keep proper tension on

the blade at all times using the

blade tension adjustment.

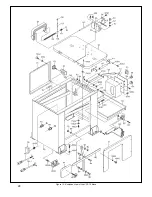

3. Loosen the two bottom bolts

(Figure 6, Item B) on the wheel

slide.

While performing the following

steps, keep the blade from

rubbing excessively on the

shoulder of the wheel.

Excessive rubbing will

damage the wheel and/or the

blade.

4. Start the saw. Turn the setscrew

to tilt the idler wheel until the

blade is touching the shoulder

of the idler wheel.

5. Turn the setscrew (Figure 6,

Item A) so the blade starts to

move away from the shoulder of

the wheel; then immediately

turn the setscrew in the other

direction so the blade stops;

then moves slowly towards the

shoulder.

Figure 6: Blade Tracking Adjustment