17

Keep your fingers clear of the blade and wheel to avoid injury.

6. Turn the setscrew to stop the motion of the blade on the wheel as it gets closer to

the wheel shoulder. Put a six-inch length of paper between the blade and the

wheel. The paper should not be cut as it passes between the wheel shoulder and

the blade.

7. Turn the setscrew a small amount. Repeat the insertion of the paper between the

wheel shoulder and the blade until the paper is cut in two pieces.

NOTE: You may have to repeat the check with the paper several times before the

blade and the shoulder cut the paper into two pieces. Do not hurry the

adjustment. Patience and accuracy here will pay off with better, more accurate,

quieter cutting and much longer machine and blade life.

8. When the paper is cut, turn the setscrew slightly in the counterclockwise direction.

This assures that the blade is not touching the shoulder of the wheel.

9. Shut off the saw.

10. Tighten the two bottom bolts on the upper wheel slide (Figure 6, Item B).

Blade Guide Bearing Adjustment

Proper adjustment of the blade guide bearings is critical to efficient operation of the band

saw. The blade guide bearings are adjusted at the factory. They should rarely require

adjustment. When adjustment is required, readjust immediately. Failure to maintain

proper blade adjustment may cause serious blade damage or inaccurate cuts.

It is always better to try a new blade when cutting performance is poor. If performance

remains poor after changing the blade, make the necessary adjustments.

If a new blade does not correct the problem, check the blade guides for proper spacing.

For most efficient operation and maximum accuracy, provide 0.001” clearance between

the blade and the guide bearings. The bearings will still turn freely with this clearance. If

the clearance is incorrect, the blade may track off the drive wheel.

Disconnect the band saw from its electrical power source.

Check the blade to make sure the welded section is the same thickness as the

rest of the blade. If the blade is thicker at the weld, the guide bearings may be

damaged.

If required, adjust the guide bearings as follows:

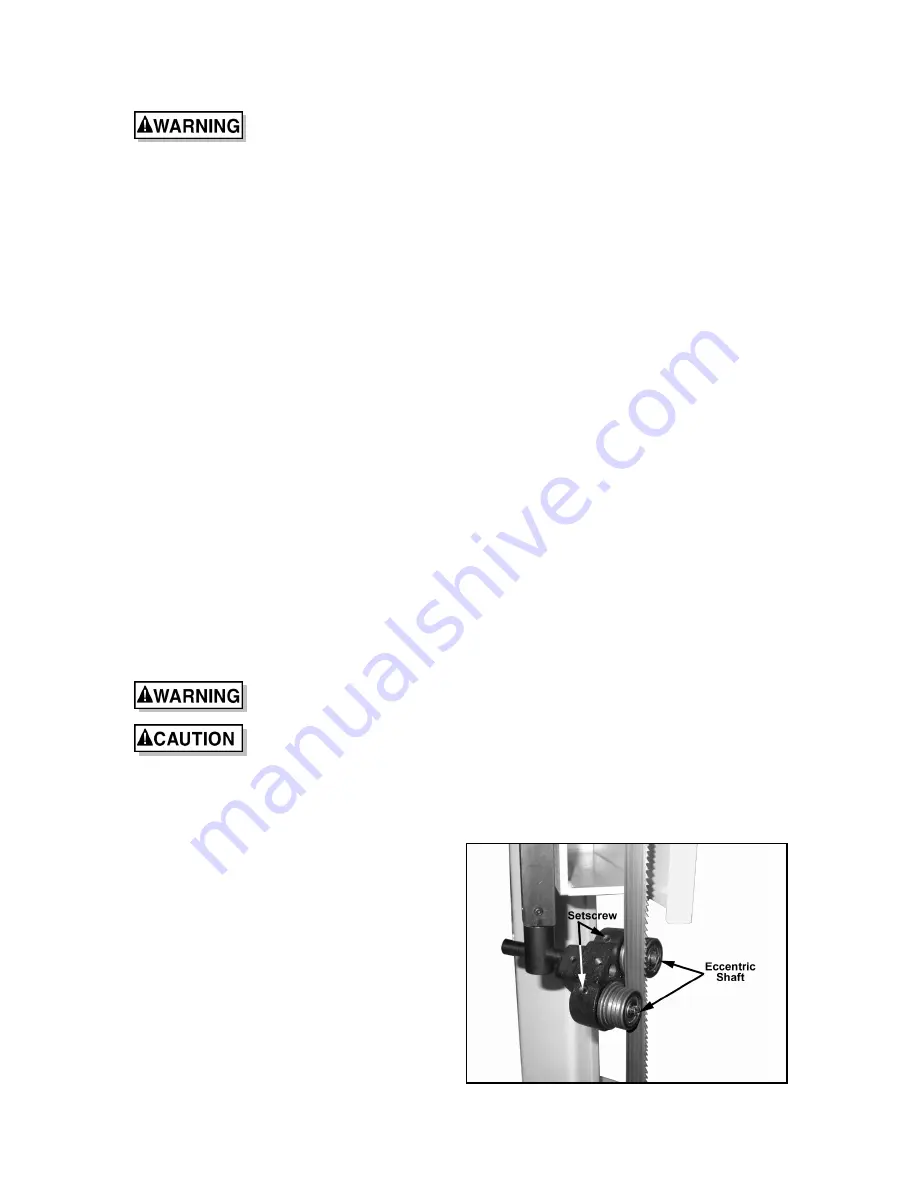

1. The upper and lower blade guides are adjusted the same way.

2. Loosen the blade guide setscrews with an Allen wrench.

3. Position the bearing by turning

the eccentric shafts. Set the

clearance to approximately

0.001”. (See Figure 7).

4. Tighten the blade guide

setscrews with the Allen

wrench.

5. Use the same procedure to

adjust the other blade guide

bearing.

6. When the adjustment is correct,

the guide bearings should

rotate freely with slight pressure

of the finger (blade stopped).

Figure 7: Guide Bearing Adjustment