19

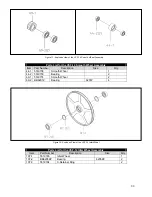

Disconnect the band saw from its electrical power source.

1. Remove the two screws and washers holding the brush or scraper on.

2. Remove the worn brush or scraper.

3. Install the replacement brush or scraper.

4. Install the two screws and washers.

5. Adjust the brackets, if necessary, so that the brush makes slight contact with the

lower blade wheel and the scraper is as close as possible to the saw blade

without touching it.

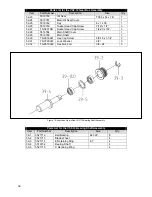

Blade Guide Bearing Replacement

Disconnect the band saw from its electrical power source.

1. Remove the saw blade. (Refer to Blade Removal and Installation).

2. Remove the bearing locking screw

3. Remove the damaged bearing and bushing.

4. Separate the damaged bearing from the bushing.

5. Install the replacement bearing on the bushing.

6. Install the bearing locking screw.

7. Install the saw blade. (Refer to Blade Removal and Installation).

8. Adjust the bearing clearance. (Refer to Blade Guide Bearing Adjustment).

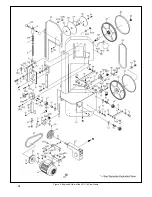

Drive Motor Replacement

Disconnect the band saw from its electrical power source.

1. Remove the drive motor V-belt. (Refer to Changing the Drive Motor V-Belt).

2. Loosen the setscrew that holds the motor pulley to the shaft and remove the

pulley.

3. Open the motor junction box and disconnect the power cord wires from their

terminals.

4. Remove the nuts, washers and bolts that secure the motor to the mounting plate.

5. Installation of the motor is the reverse of the above steps. (Refer to Changing the

Drive Motor V-Belt and the electrical schematics at the end of this manual).

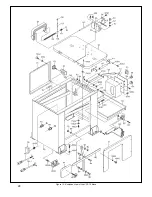

Adjusting or Replacing the Counterbalance

The counterbalance is located on the base of the saw. It is used to adjust the amount of

force the saw puts on the work piece when the hydraulic control cylinder is open.

Disconnect the band saw from its electrical power source.

1. Lock the saw frame in its rearmost position by pushing down on the saw frame

release lever (Figure 3 Item 2) and lock it in place by turning the saw frame

release knob (Figure 3 Item 1.2) clockwise.

2. Turn the handle on the counterweight counterclockwise to loosen it (Figure 3

Item 9).

3. Slide the counterweight along the bar to the proper location.

4. Turn the handle on the counterweight clockwise to tighten it (Figure 3 Item 9).