4.1 Connect the wire rope links and turnbuckles to the holes on square block on

the motor.

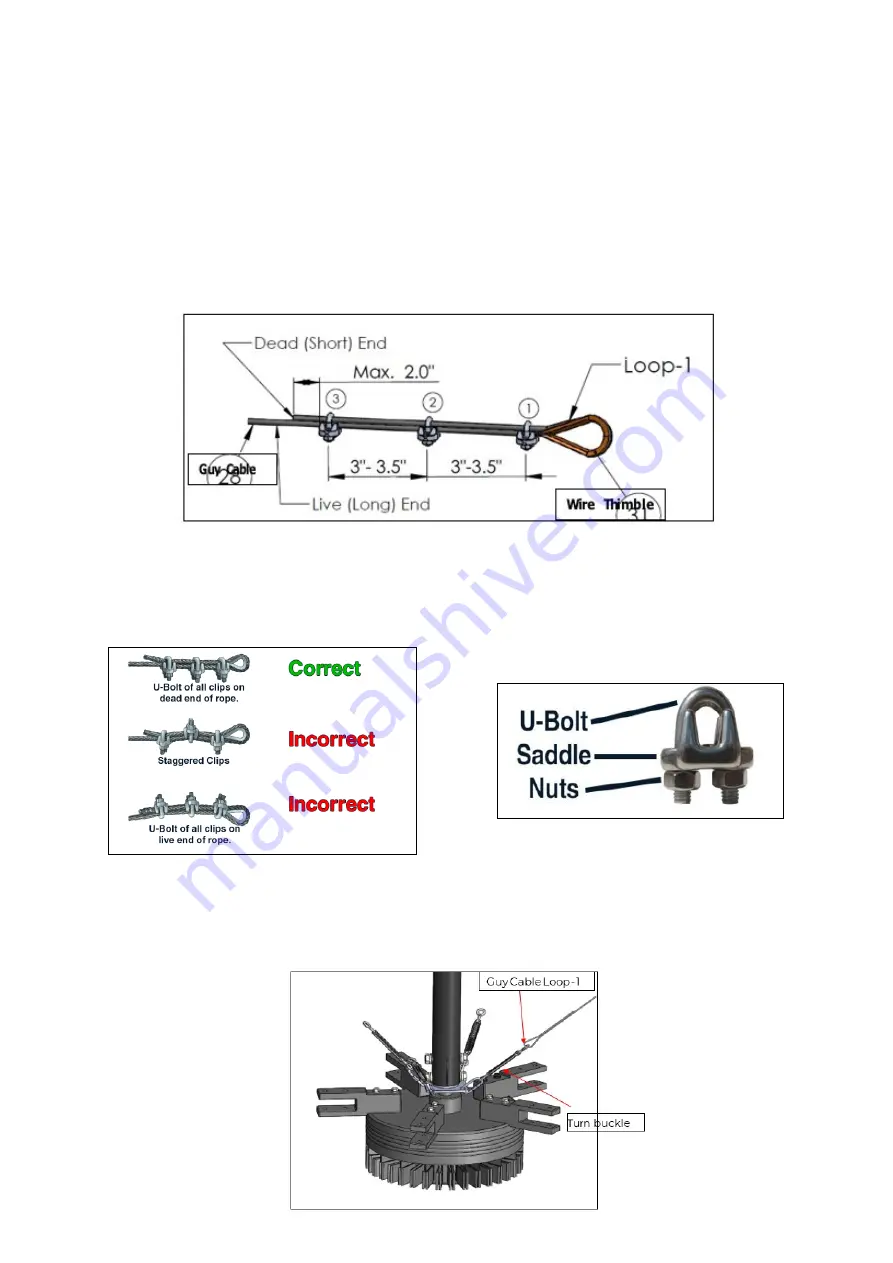

4.2 Making the Guy Cable Loop-1: Prepare Guy Wire Loop-1 at one of the guy cable

using a Wire Thimble and three Wire Rope Clips. Install the first wire rope clip

adjacent to the wire thimble followed by the second and third wire rope clips at

7.5cm - 9cm apart from each other. Dead end of the guy cable should not extend

more than 5cm out from the third wire rope clip. Be sure that all the wire rope

clips are tightened properly and installed correctly.

Wire Rope Clip

Below is a diagram showing proper clip installation, it is imperative that you

install the saddle on the live end of the wire rope.

4.3 Connect the supplied Turnbuckles and Guy Cable loop-1 to the eyes of the Slip

Rod as shown in the below figure.