J etma ster

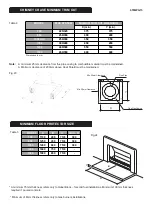

Fig. 6

Fig. 7

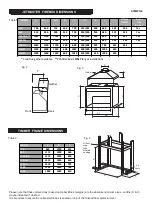

Timber Framing

75mm min Hebel Block or

100mm Concrete

Note: Ensure allowance

made for firebox to sit

on top of finished Floor

Protector level

Margin leg to be no less than

90mm wide

All Hebel Block margins have been made to fit firebox timber frame trim out dimensions (see Table 2).

Suggested method to cut Hebel Block - skill saw fitted with masonry blade.

Under no circumstance is the width of the vertical margin legs to be less than 90mm and the height of the

margin lintel to be less than 300mm (see Fig 5).

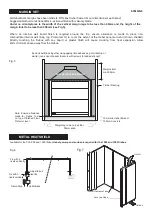

Where an internal wall board finish is required around the fire, ensure allowance is made to place non-

combustible internal wall lining (eg: Promatect H) to cover the extent of the Hebel panel surround (shown shaded).

Directly touching the firebox with any board or plaster finish will cause cracking from heat expansion. Allow

2mm minimum space away from the firebox.

Bond Hebel Block together using appropriate adhesive eg: Gorilla Grip or

similar (non-solvent based) & secure with screws for added strength

Fig. 5

Margin Lintel

min 300mm

Non Combustible Board

Fix with 3

rivets vertically

Frame Stud

Hebel Block

Fix with 3

rivets vertically

Adjust to suit

rivet fix

25mm Clearance Tabs

Securing Flaps

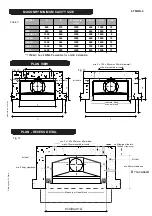

Cold Air

Hot Air

METAL HEAT SHIELD

Available for the 700, 850 and 1050 firebox

Hebel power panel enclosure required for the 1200 and 1500 firebox.

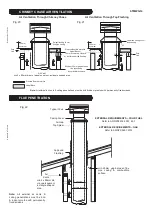

MARGIN SET

6.TMWG.5