With flues of greater efficiency or taller chimneys, smoke clearance may be possible with the air supply lever almost

completely closed. Note that in the latter case, a small area is left open to guarantee chimney ventilation.

Damping down over long periods (overnight) with logs, the fire should be allowed to die down before banking up

the fuel and closing the air supply to the minimum while maintaining smoke clearance. Banking up and closing

the air supply on a hot fire may cause the fire to roar away, overheat and burn out quickly. The right technique

comes with a little experience, and varies with the fuel being burnt.

Seasonal Use

In the summer months or at times when the fire is not being used then the air supply lever may be closed to

eliminate draughts and to minimise the air loss from the room.

Fuels

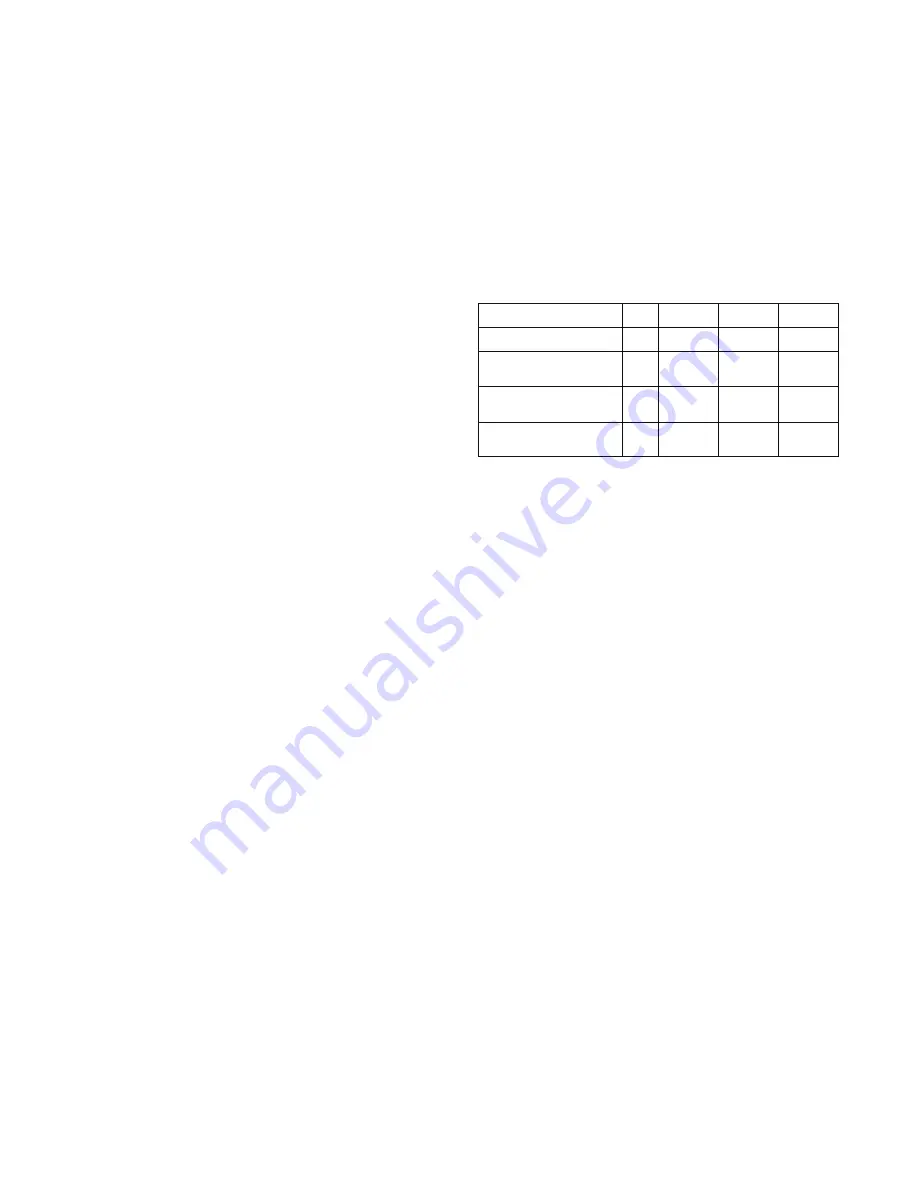

FUEL DATA

MODEL

WOOD

MAXIMUM WOOD SIZE

Length & Diameter

MAXIMUM REFUEL

WEIGHT

MINIMUM REFUEL

INTERVAL

mm

Kg

Min

18i

200 Lth

Ø100

1.75*

60*

60i

400 Lth

Ø100

2.25*

60*

70i

500 Lth

Ø100

3*

60*

The data marked * on the 18i and 70i are Jetmaster estimated figures

The table shows the recommended fuel sizes, weights

and refuel interval to achieve the outputs given on

page 5 in accordance with EN13229: 2001.

Recommended Fuel Types

1. Smokeless Fuels

Smokeless fuels may be burned in basket grates.

Use smaller lumps and some slack when banking

down for longer periods of unattended burning.

Of the smokeless fuels, Coalite, Homefire and

Anthracite are particularly suitable. Furnace fuels

and petroleum based solid fuels should not be used

in Jetmaster Stoves.

2. Wood (Recommeded and approved fuel for fire to meet requirement of EN13229:2001)

Wood has about half the calorific value of coal, on a weight for weight basis. “Green” wood has a high moisture

content, which makes it difficult to burn, and reduces net heat output.

Buying a load of green firewood means you may have been buying as much water as you are wood. When wood

is burned, the water content is converted into steam. The large amount of heat necessary to do this accounts for

the reduction in useful heat. Air-drying, or seasoning, reduces moisture content, thus making it easier to burn.

Where green wood must be burned, first build to a strong heat to ensure that enough excess heat is produced

to dispose of the moisture.

The readiness of wood to burn depends on the density and the size of each piece. Denser hardwoods are

generally better than softwoods such as pine, which when dry burn fast and split. A split log will catch and burn

better than a full round log. Only well seasoned wood should be used. This also helps to burn off more of the

tars, and to reduce the build up of tar deposits.

The fire burning rate can thus be controlled by the amount of fuel that is used the size of fuel and the refuelling

interval as well as the control of the air supply lever. Kindling wood will burn fast, split logs at a medium rate and

whole logs a little slower. So by mixing the sizes that are burnt and used in conjunction with the air supply control

the fire rate of burn and hence output can be controlled.

Any of the dense hardwoods are recommended such as:- Birch, Beech, Hornbeam, Oak, Ash, Elm and numerous

others not mentioned.

Cleaning and Maintenance

The visible front parts of the fire can be repainted with heat resistant black paint. These parts can be repainted

every 1 or 2 years as required but generally dusting with a soft brush should keep the fire looking good. The

interior of the firebox and the grate should not be painted.

To maintain the finish on Decorative Surrounds wipe with a soft damp cloth only.

Do not use

abrasive cleaners,

polish or solvents as these can damage the surface finish.

Glass Door

If over a period of time the glass door starts to soot then this maybe cleaned with a proprietary cleaner available

from your dealer.

ALL CLEANING MUST BE CARRIED OUT WITH THE APPLIANCE COLD.

28

Summary of Contents for INSET STOVE MKIII 60i

Page 35: ...35...