D

A

F

E

B

E

D

A

D

A

C

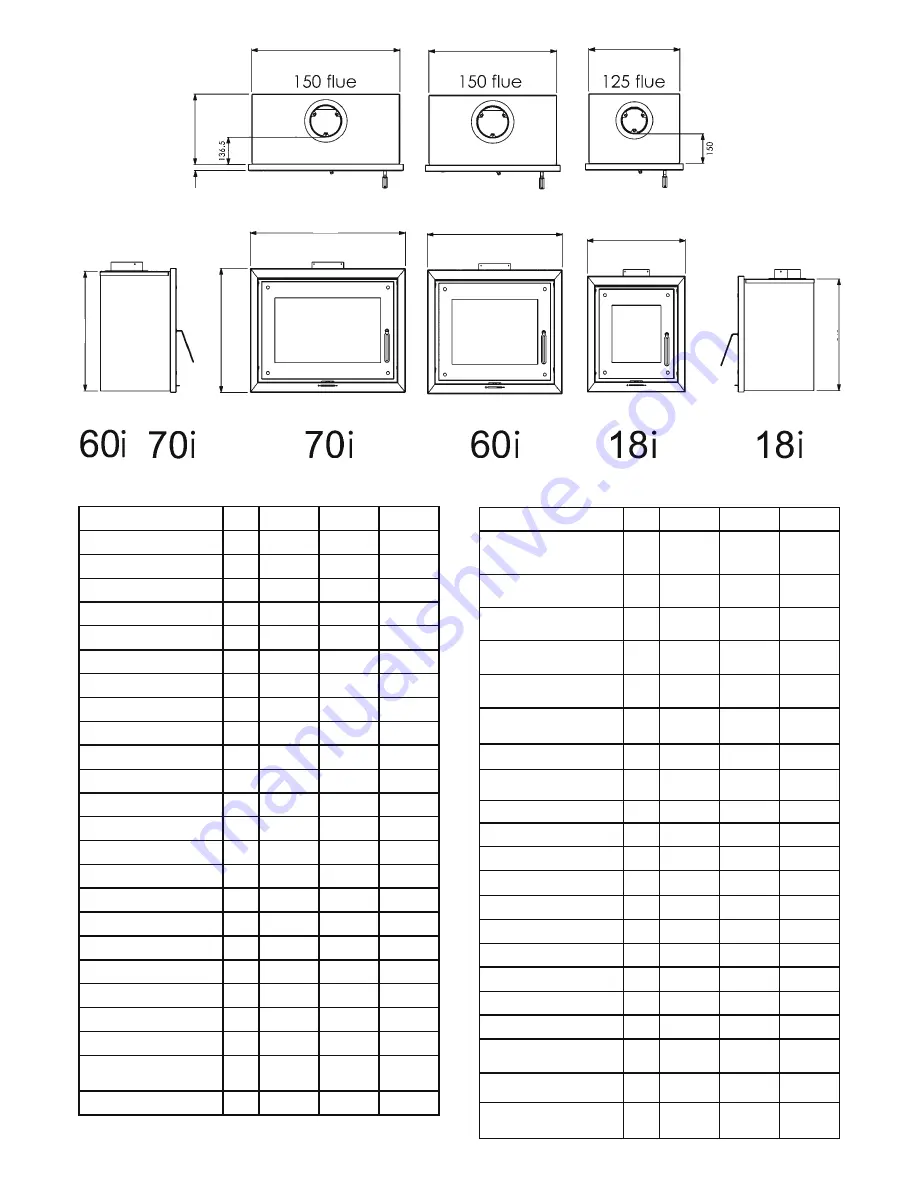

DIMENSIONS

MODEL

FRAME/TRIM

WIDTH

HEIGHT

DEPTH

OUTER FIREBOX

WIDTH

HEIGHT

DEPTH

OPENING REQUIRED

WIDTH

HEIGHT

DEPTH

WEIGHT

OUTPUTS /

TEMPERATURES WOOD

ROOM SIZE HEATED

TOTAL NOMINAL HEAT

OUTPUT WOOD WHEN

TESTED TO EN13229: 2001

NET EFFICIENCY WOOD

TO EN13229: 2001

FLUE GAS TEMPERATURE

TO EN13229: 2001

FLUE GAS MASS FLOW TO

EN13229: 2001

MEAN CO2 IN FLUE GAS

TO EN13229: 2001

MEAN CO @ 13% O2 TO

EN13229: 2001

FLUE SIZE

MINIMUM FLUE SIZE

DIAMETER

MINIMUM FLUE AREA

MINIMUM FLUE DRAUGHT

CHIMNEY HEIGHT

ABOVE FIRE

AIR SUPPLY

AREA

MAXIMUM WOOD SIZE

Length & Diameter

MAXIMUM REFUEL WEIGHT

MINIMUM REFUEL

INTERVAL

A mm

ins

B mm

ins

C mm

ins

D mm

ins

E mm

ins

F mm

ins

mm

ins

mm

ins

mm

ins

Kg

M³

kW

%

°C

gs-1

%

%

mm

in

cm

2

in

2

Pa

M

ft

cm

in

mm

Kg

Min

18i

488

19

1

/

4

571

22

1

/

2

30

1

3

/

16

449

17

3

/

4

549

21

5

/

8

347

13

3

/

4

457

18

554

21

7

/

8

355

14

85

100*

5*

84% *

X

X

X

X

125

5

123

20

12

4.5

15

0

0

200 Lth

Ø75

1.75*

60*

60i

670

26

3

/

8

610

24

30

1

3

/

16

631

24

7

/

8

588

23

1

/

8

347

13

3

/

4

647

25

1

/

2

593

23

3

/

8

355

14

95

150

7.5

84

292

4.17

14.48

0.24

150

6

177

28

12

4.5

15

14

2.5

400 Lth

Ø100

2.25

60

70i

770

30

1

/

4

610

24

30

1

3

/

16

731

28

7

/

8

588

23

1

/

8

347

13

3

/

4

747

29

1

/

2

593

23

3

/

8

355

14

110

200*

9.5*

80%*

X

X

X

X

150

6

177

28

12

5.0

16.5

25

4

500 Lth

Ø100

3*

60*

The data marked * on the 18i and 70i are Jetmaster estimated figures

5

MODEL

18i

60i

70i

Summary of Contents for INSET STOVE MKIII 60i

Page 35: ...35...