Baby Lock Jewel Service Manual

© Baby Lock, all rights reserved

37

•

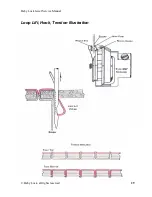

Carriage on backwards – long overhang goes to the machine front by needle.

•

Rubber wheel has come off encoder assembly: was pealed off the encoder assembly

when the machine was removed from box, came off because machine was slid

sideways on a surface before machine was placed on carriage

•

Ran over encoder cable with the machine metal wheel before connecting it damaging

it.

•

Cables not plugged into the two encoders and the c-pod..

•

Rear machine encoder bracket bent by sliding the machine sideways.

•

Rear machine encoder stop bent down holding wheel up off carriage track.

•

Carriage encoder bracket bent.

•

Small rubber wheel not riding on bottom plastic part of track.

•

Wheel not on track – bracket bent.

•

Encoder wheel loose on axle – 1/16” Allen tool screw loose.

•

Spring came out partially or completely from under base plate on rear encoder wheel

assembly.

Operation Problems:

•

Moving too fast or slow or with too much irregularity or quick speed variations.

•

Did not hit “select” the 2

nd

time to fully activate the stitch regulator.

•

Not aware that they must move slower with more stitches per inch (SPI), e.g. 15 SPI

and that they can move faster with less SPI, e.g. 4.SPI