3. ADJUSTMENTS AND DRIVING

FLOW CAPS

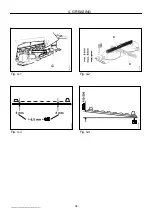

Fig. 3-12 The discs are equipped with flow caps to ensure that the crop is lifted away from the

blades faster. This reduces risk of stripes and recutting.

If the power requirement seems to be too high, the flow caps can be dismounted.

The amount of crop and the driving technique determine the need of flow caps.

SWATH GUARDS

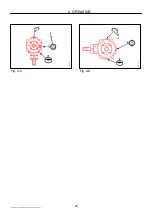

The swath guards on the machine must ensure that the swath has the wanted shape

and width. The crop is thrown from the conditioner rotor to the rear to the swath

guards which gather the crop in an airy, narrow swath with a rectangular cross

section.

Such a swath provides optimal preconditions for effective drying and subsequent

unproblematic picking up for a forage harvester or a baler.

Fig. 3-13 The width of the swath can be adjusted by turning the swath guards. The

bolts/handles on the top plate are loosened and the guards are moved either out or

in.

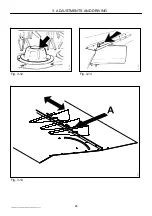

EQUIPMENT FOR WIDE SPREADING (TOP DRY) ON SM MODELS

The GX machines with finger conditioner (SM models) are fitted with a number of

spreading plates which make it possible to place a full-width swath to obtain optimum

drying.

Fig. 3-14 All spreading plates can be adjusted separately in oblong holes. This is simply done

by loosening the eye nuts and moving the spreading plate to the wanted position.

The factory setting for each spreading plate is marked with an indicator hole A.

NB: To place a normal swath, it is necessary to dismount the outermost spreading

plates in each side to be able to turn the swath guards into the wanted position.

PIGB-093X-06 GX 2402/2802/3202 SM-GX 2402/2802 SC 0410

27