5. MAINTENANCE

All machines manufactured by JF-Fabriken are tested and checked for vibrations with

special tools.

The first time you start the machine pay attention to vibrations and noise to have a

standard of comparison later.

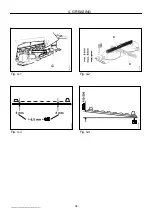

Fig. 5-4 To avoid damage caused by vibrations in the cutting unit, the cutter bar must be

fastened correctly. The 4 bolts F in each side must be tightened to 110 Nm (11 Kpm).

Fig. 5-5 Bolts at stone protectors and shearbars at the front of the cutter bar should be

checked at regular intervals.

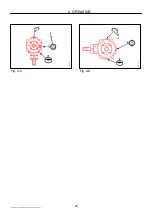

Fig. 5-6 The two large flow intensifiers G on the outermost discs are filled with foam blocks H

to avoid unbalance. It is important that the foam blocks remain undamaged to

prevent the flow intensifiers from being filled up with earth, dust and impurities which

may cause unbalance.

Fig. 5-7

The low flow caps I on the remaining discs should be straightened if they are

deformed and, if necessary, be replaced by new ones. Dismount the flow caps and

clean of earth, dust etc. 2 – 3 times during the season.

CUTTER BAR – DISCS AND BLADES

Discs, blade bolts and blades are made of high-alloyed, hardened materials. This

heat treatment provides especially hard and ductile material which is able to

withstand extreme stress. If a blade or a disc is damaged, do not attempt to weld the

parts together again as the generation of heat will weaken the parts.

Damaged blades, discs, blade bolts and nuts must be replaced by original -JF-

spare parts to obtain a safe operation.

WARNING:

When replacing blades, both blades on the disc in question

must be replaced as not to create an unbalance.

CAUTION:

Always lower the cutting unit to the ground before replacing

blades, blade bolts, discs and the like.

BLADES

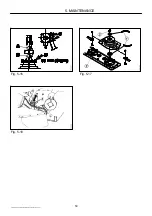

Fig. 5-8

Blades must be replaced if:

- the blade width is less than 33 mm measured 10 mm from the edge of the

disc.

- the metal thickness around the blade hole is less than 10 mm.

Bent blades must be replaced immediately.

Blade bolts and nuts must also be checked regularly, especially the tightening of the

nuts. Especially after collision with foreign matter, after replacement of blades and

the first time you use the machine.

Fig. 5-9

Blade bolts must be replaced if:

1)

they are deformed

2)

they are strongly worn on one side

3)

the diameter is less than 15 mm.

PIGB-093X-06 GX 2402/2802/3202 SM-GX 2402/2802 SC 0410

47