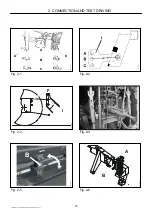

2. CONNECTION AND TEST DRIVING

2. CONNECTION AND TEST DRIVING

CONNECTION TO THE TRACTOR

First, the machine should be adjusted to the track width of the tractor.

Fig. 2-1

You can choose between 3 settings (A, B and C) of the pins on the headstock

corresponding to the following track width sizes.

Track width [mm]

Pin position

< 1650

A

1650 – 1850

B

> 1850

C

The adjustment of the pins is made by loosening and adjusting the fixed pin and

adjusting the loose pin according to fig. 2-2.

Fig. 2-2

Choose middle hole B in the lever arm I at the left coupling point.

WARNING:

Category III link arms can in hole A break the spring tightener

Fig. 2-1

Connect the link arms of the tractor to the coupling points D of the machine.

Fig. 2-3

Mount the top link F so that it is approximately parallel with the link arms of the

tractor.

Thereby a suitable movement is achieved when lifting the machine with the link arms

and optimal conditions for later connection and disconnection of the machine.

Fig. 2-4

Connect the hydraulic hoses to a double-acting hydraulic outlet.

Place the machine in working position by first raising the link arms, then activate the

double-acting outlet, and at the same time actuate the valve by pulling the cord.

Fig. 2-5

Release the transport lock B.

Fig. 2-6

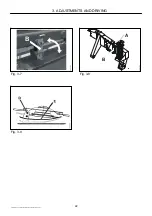

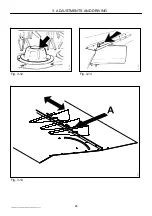

Adjust the relief of the machine as follows:

1) Place the handle for the double-acting hydraulic outlet in floating position.

2) Raise/lower the link arms of the tractor until the indicator A is on level with the

arrow on the transfer B.

3) Lock the link arms in this position.

A lighter machine (lower ground pressure) is obtained by raising the link arms so the

indicator A moves approximately 1 cm down towards + on the transfer B.

A heavier machine (higher ground pressure) is obtained by lowering the link arms so

the indicator A moves approximately 1 cm up towards - on the transfer B.

PIGB-093X-06 GX 2402/2802/3202 SM-GX 2402/2802 SC 0410

17