With User to Create Better Product

10

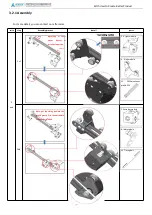

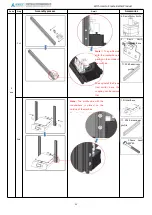

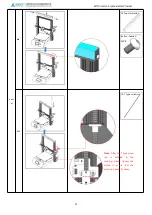

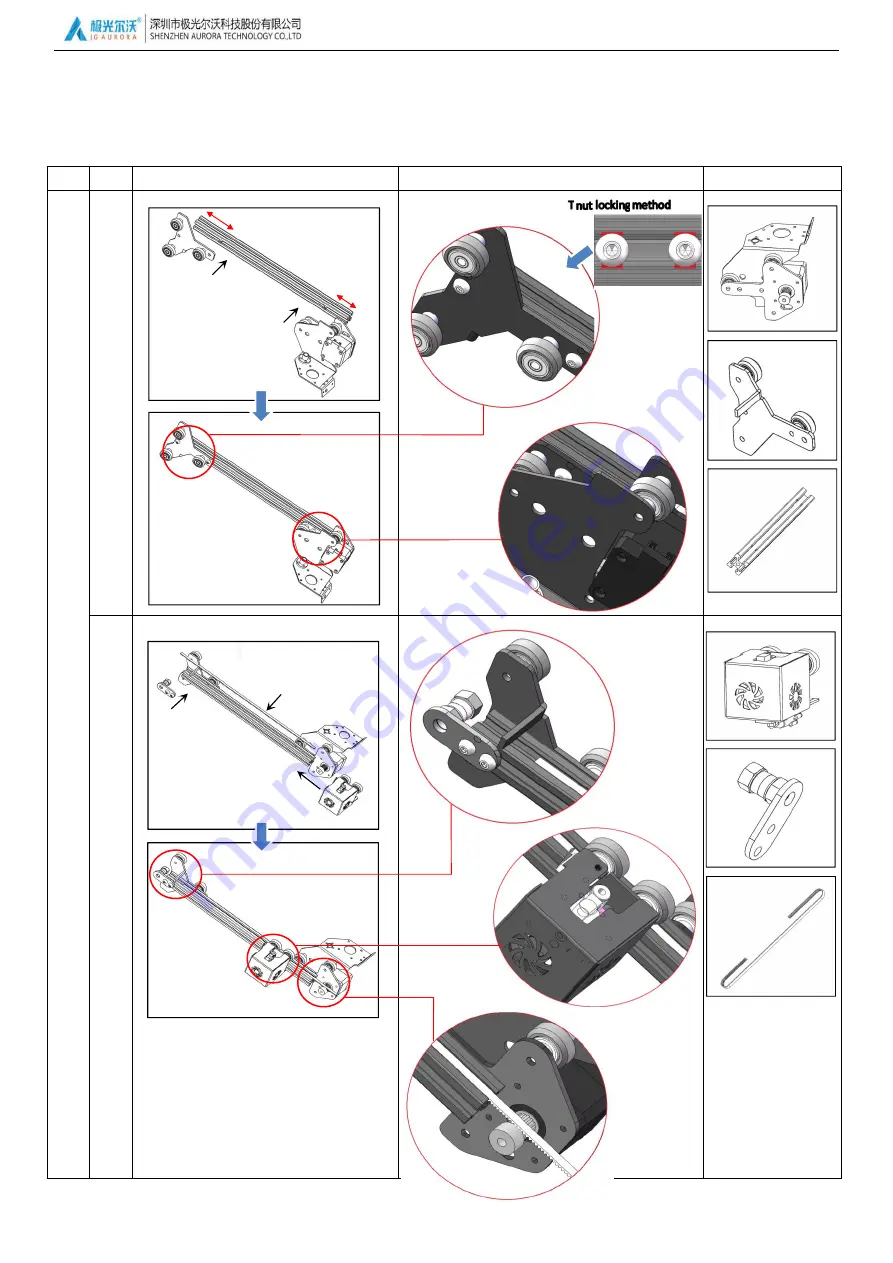

3.2.1 Assembly

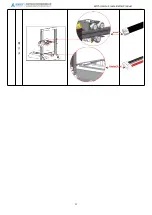

For more detail, you can contact our after sales.

suite

step

Assembly process

detail

parts

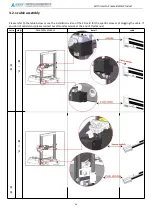

X

axis

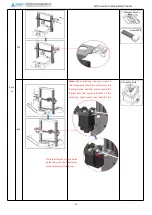

1st

2nd

long

short

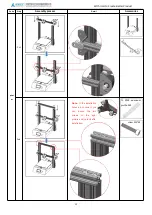

4. X left module

3. X right module

13.

2020aluminum

profile-350

2. Extruder module

14. Timing belt

8. Idler module

Note: put the timing belt into the

profile groove first, then,assemble

the extruder module

Note:long or short

means

distant of

install hole position

。