10

EN

Number

Speed(/min)

600

600

1000

1000

1400

1400

1800

1800

2200

2200

2600

2600

3000

3000

3500

3500

Caution: The constant speed and power

controller can be turned only as far as 3500 and

back to 600. Do not force it past 600 or 3500, or

the speed adjusting function may no longer work.

●

Polishing Operation

Please adjust the speed to a lower speed when

used the machine as a polisher.

*Caution: Always wear goggles and mask

during operation.

1. When using the tool for polishing, do not

force the tool on the surface of the workpiece

to be polished. Sometimes the weight of

the tool applies adequate pressure. Forcing

and excessive pressure will result in poor

performance and dangerous. At the same time, it

will also lead to tool overload and motor burning.

2. Sanding disc, polishing oil or wax oil should be

selected in accordance with the material and

desired surface finish. Maximum polishing effect

will be attained by following method:

Preliminary polishing with sander using a fine-

grain sanding disc.

Polishing with a polishing guard using polishing

oil or wax. Apply a small quantity of oil or wax on

the material surface before polishing.

Caution: When using the tool for polishing,

do not force the tool on the surface of the

workpiece to be polished. Sometimes the

weight of the tool applies adequate pressure.

Forcing and excessive pressure will result in

poor performance and dangerous. At the same

time, it will also lead to tool overload and motor

burning. Apply polishing oil or wax oil on the

workpiece in accordance with the material and

desired surface finish before polishing.

Maintenance and Care

Caution: Always be sure that the tool is

switched off and unplugged before attempting

to perform inspection or maintenance.

●

Clean the air vents

The air inlet and air outlet of the tool should be

cleaned regularly or at any time when it is blocked.

1

2

1.Air Outlet

2.Air Inlet

●

Check the mounting screws

Should always check whether mounting screw

fastening safely. If found loose screws, shall be

immediately to tighten, so as to avoid an accident.

●

After Use

Do not put down the tool immediately after the tool

is turned off. Wait until the tool completely stops

before putting it down. This can not only avoid

accidents, but also reduce a large amount of dust

and fine debris being sucked into the tool.

●

Check the Carbon Brushes

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark.

Keep the carbon brushes clean and free to slip

in the holders. Both carbon brushes should be

replaced at the same time.

1

1.Limit Mark

●

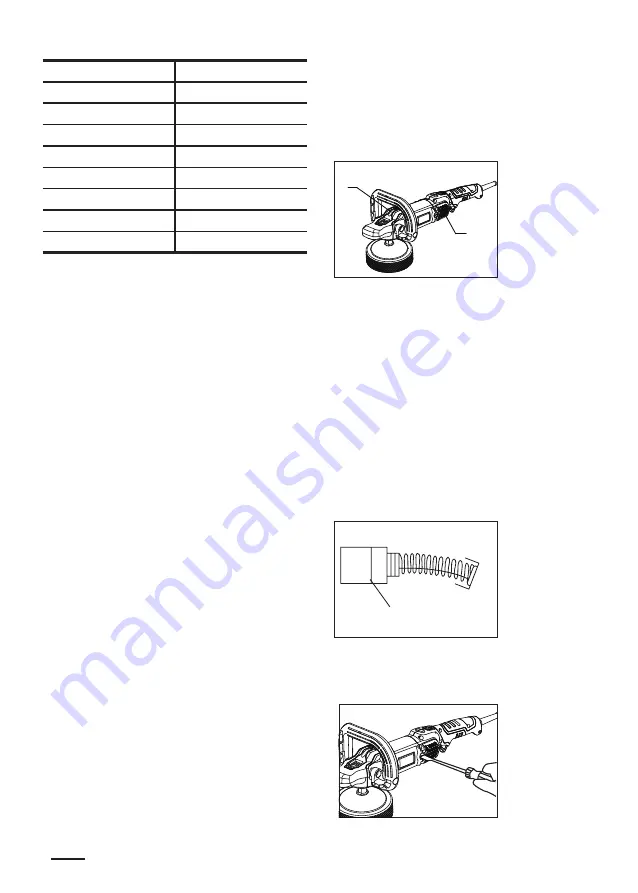

Replace the Carbon Brushes

Use a screwdriver to remove the brush cover, take

out the worn carbon bush and replace a new one,

and then tighten the brush cover securely.

Summary of Contents for DSP05-180

Page 1: ...ES DSP05 180 ASP05 180 KSP05 180 EN FR 2 14 27...

Page 13: ...13 EN...

Page 26: ...26 FR...

Page 39: ...39 ES...