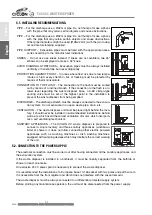

7.1. CLEANING.

In order to clean the lavatory connected to the waste disposer, it is recommended to use any market

high-quality cleaner with no acid components.

In areas with a high level of water hardness and for the purpose of eliminating the lime deposits, it is

recommended to clean regularly the appliance as follows:

- Disconnect the waste disposer from the electrical current.

- Pour into the lavatory a mixture of roughly 1 litre of vinegar and 3 litres of water.

- Leave the mixture to work for some hours.

- Connect the waste disposer again and start it.

7.2. TROUBLESHOOTING GUIDE.

Before performing any operation, please verify the following steps:

- Check that the filling and discharge mechanisms of the lavatory cistern are in good condition, and the

water supply to the cistern remains open.

- Check that the waste disposer in connected to its socket for a proper working, and check it is working

(by checking that the differential has not tripped and the magneto thermal circuit breaker remains

connected)

- Please check the waste disposer thermal disconnection system has not been set in motion (the waste

disposer includes an automatic disconnection system in case of extremely high temperatures), by

waiting roughly 20 minutes (may vary depending on temperature conditions).

- In case of an excessively long operating, or if the waste disposer is started continuously, please check

if there is any sort of leaking from the cistern to the lavatory or in the rest of the connected appliances.

- You must also check that there is no return to the waste disposer through the non-return valve of the

evacuation pipe due to an inappropriate closing thereof (verify that the clappet fits properly). (see repla-

cement-cleaning of the non-return valve on page 26).

26 - INSTRUCTIONS AND MAINTENANCE GUIDE

T-604 CC WASTE DISPOSER

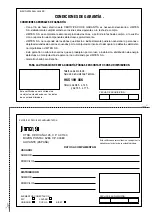

PROBLEM

REASON

SOLUTION

- The waste disposer does not start.

- It is disconnected.

- The electrical connection fails.

- The thermal protection circuit has been

activated.

- Connect the unit properly.

- Check the electrical connection.

- Wait roughly 20 minutes until the motor

cools.

- The differential switch trips.

- Motor earth wire is defective.

- Motor out of service. Contact the T.A.S.

- The motor works, but does not discharge

or makes it slowly.

- The evacuation pipe is obstructed.

- Clean the evacuation pipe.

- The motor buzzes but does not spin.

- Turbines or blades blocked by foreign

bodies.

- See the waste disposer dismantling

(page 11)

- After the evacuation, the motor starts

and stops indefinitely.

- Escapes in the non-return valve or water

loss from the cistern or from the auxi-

liary connection.

- Clean the non-return valve of the

discharge pipe.

- Review and replace the joints of the

cistern discharger and those of the taps

from the connected sanitary appliances.

- The motor does not stop.

- Evacuation pipe is too high or long for

the diameter of pipe in use.

- Power loss due to too many elbows.

- The discharge pipe is obstructed.

- The discharge pipe is obstructed due to

lime remains.

- The micro-switch does not work properly.

- Review the evacuation installation.

- Review the evacuation installation.

- Perform the descaling process as descri-

bed (cleaning 7.1.)

- Contact the T.A.S.

English

Español

Summary of Contents for Ciclon CC T-604 CC

Page 34: ...34 INSTRUCTIONS AND MAINTENANCE GUIDE T 604 CC WASTE DISPOSER 12 INSTALLATION English Espa ol...

Page 35: ...MANUAL DE INSTRUCCIONES Y MANTENIMIENTO 35 T 604 CC WASTE DISPOSER English Espa ol...

Page 36: ...36 INSTRUCTIONS AND MAINTENANCE GUIDE T 604 CC WASTE DISPOSER 12 MAINTENANCE English Espa ol...